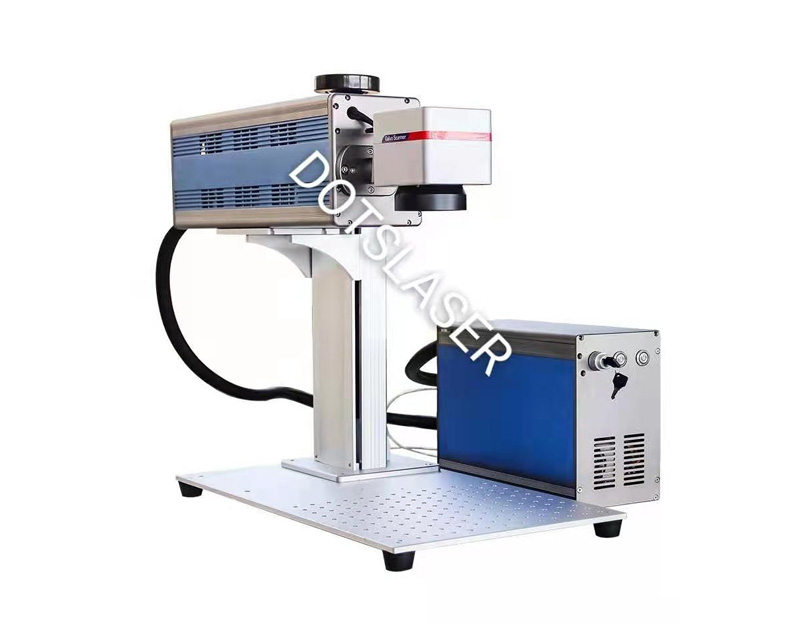

CO₂ Laser Engraving on wood products

CO2 small power laser machine is best solution for engraving wood products, Co2 laser marking machine is mainly applicable for many non-metallic materials like leather,textile,film,wood,acrylic,bamboo,board,paper,plastic,stones,ABS,PVC,PC, and so on. It is used in gifts, advertising decoration, toys, electronic appliances, medicine, food,automobile,packaging, and other industries.

Video shows:

What is best wood for laser engraving?

1. Maple - Maple wood is suit for laser engraving,due to its light color,even grain,it is easy to engrave. It engraves well and produces a crisp, clear image.

2. Cherry - Cherry wood have some advantages for laser engraving.Cherry wood hase a warm, reddish color and a rich, lustrous grain that

gives laser engravings a beautiful, natural look.

3. Alder -Alder wood has a light color and a consistent, straight grain that makes it became one of the a good choices for

laser engraving text and logos.

4. Walnut - Walnut wood has a rich, dark color and a striking, swirling grain that makes it a best materials and good choice for

laser engraving artwork and designs.

5. Bamboo - Bamboo is a sustainable wood that engraves well and produces a unique, textured look.In summer,it's help to

decrease the overheat temperature influence.

When choosing wood for laser engraving, it’s important to consider the type of image or design you want to create. Some woods may be better suited for intricate designs,

while others may work better for text or logos.

Ultimately, the best wood for laser engraving will depend on your personal preferences and the specific project you’re working on.

What can we use laser engraving for wood products?

1. Personalized Gifts: Wooden gifts are always cherished, and laser engraving makes them even more special. You can engrave a friend or loved one's name,

a special date or message onto wooden jewelry boxes, photo frames, or other keepsakes.

2. Business Advertising: Wood is a great material for creating business cards and promotional materials. Engrave your company logo, website,

and contact information onto wooden business cards or wooden signs to impress potential clients and customers.

3. Decorative Art: Laser engraving can also be used to create decorative art pieces on wooden plaques or wall hangings. There's no limit to what you can create,

including intricate patterns, wildlife scenes, or inspirational quotes.

4. Product Branding: Laser engraving can be used to enhance the branding of your products. Add your company logo or product name onto

wooden packaging for a unique and professional touch.

5. Home Decor: Laser engraving can also be used for creating unique home decor items, such as wooden coasters, cutting boards, or kitchen utensils.

You can engrave fun and quirky designs or even add a personalized message for a fun touch.

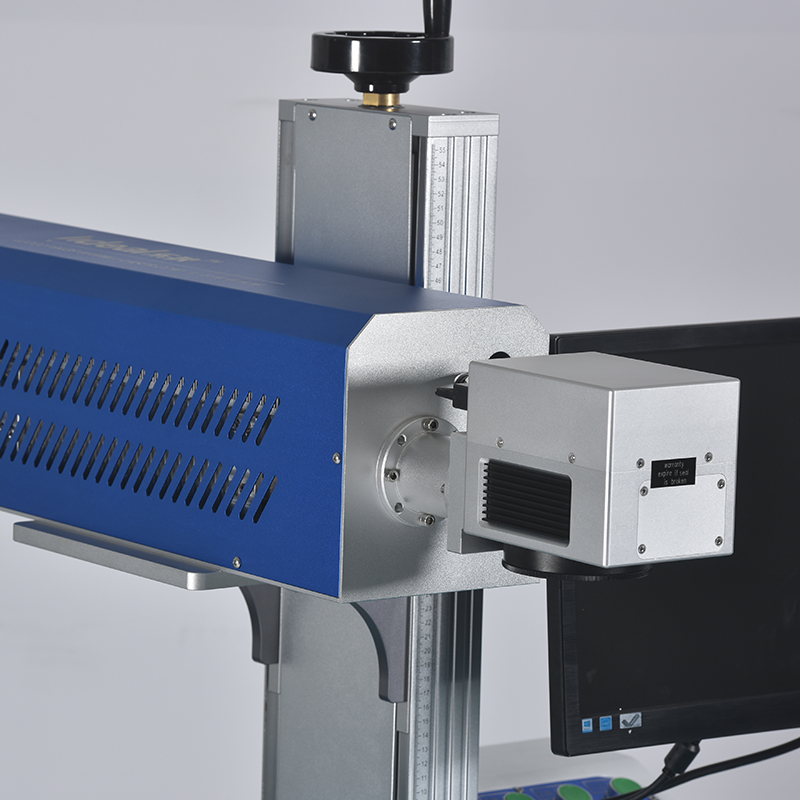

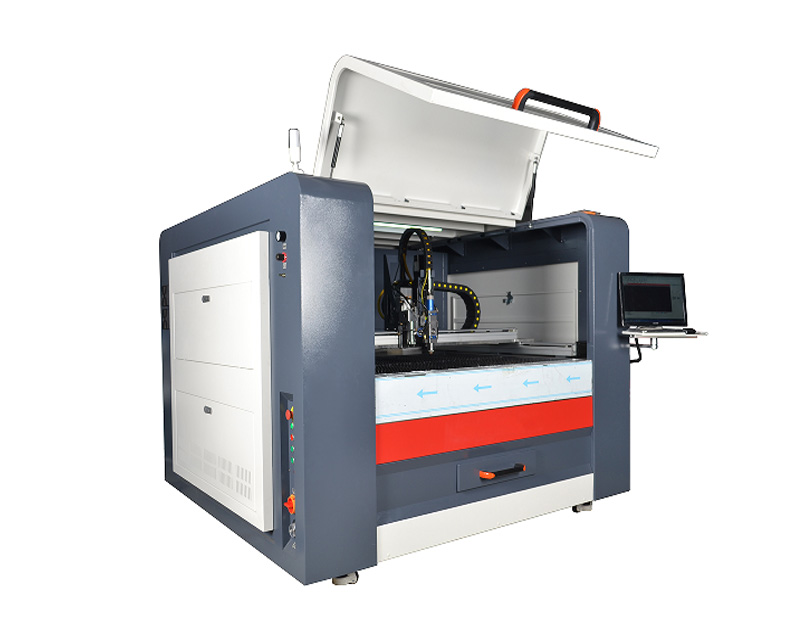

Machine parameter:

NO. | Name | CO2 laser marking machine |

1 | Machine model | DS-LM60 |

2 | Rated output power | 55W/80W |

3 | laser wavelength | 10640 nm |

4 | Laser level | Class 4 |

5 | Repeat accuracy | ±0.01mm |

6 | Min.line width | 0.1mm |

7 | Min.character size | 0.5mm |

8 | Max marking speed | 8000mm/s |

9 | Working area | 100x100mm(standard)/200x200mm/300x300mm |

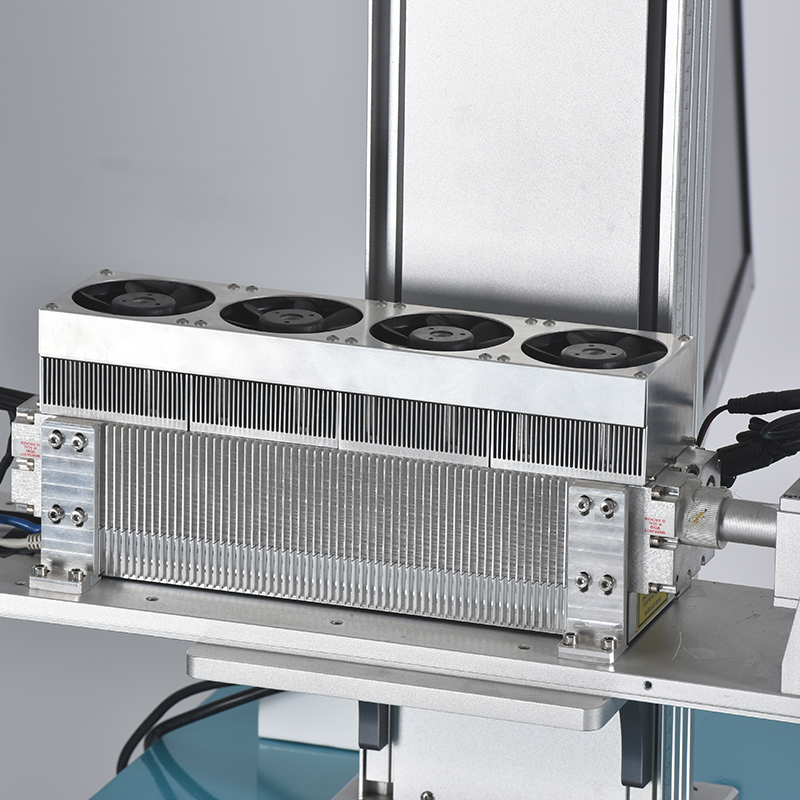

10 | Cooling | Air cooled |

11 | Working environment temperature range | 5~35 ℃ |

12 | Humidity range of working environment | < 70% No condensation |

13 | working voltage | 220V,50/60Hz |

How to operate when you start engraving?

1. Setting laser power: Appropriate laser power is key to engrave wood products well. Higher power laser enables engraving deeper mand more detailded engravings,

lower power maybe not engrave what your desired engraving effect, if you don't control the power,it may cause damage to the wood or destroy the raw materials.

2. Adjusting laser focus: Adjusting the correct focus of laser beam is essential when you plan to engrave a wood products.

A properly focused laser beam of a laser engraving machine for wood will result in a more precise and accurate engraving,

while a poorly focused laser beam may produce a blurry or uneven engraving.

3. Correcting engraving speed: The engraving speed is connected with engraving effect and quality,when lower laser moves over the surface,

it will result in a deeper and more detailed engraving, but it also need take long time to complete,with fast engraving,it may cause blurry engraving or damage the materials.

4. Choosing wood thickness: Different thickness wood engraving cause different results.Thicker wood may require a higher power laser and need spend longer time to complete,

so that to achieve the desired depth of the engraving,if use lower power laser,it may won't achieve the good engraving result.

5. Watching wood grain: The grain of the wood can also affect the laser engraving process. Wood with a consistent grain pattern will be easier to engrave accurately,

while wood with a more irregular grain pattern may be more difficult to work with.

6. Observing wood density: The wood density is a essential factor to engrave wood products well during the engraving process. Harder and denser wood

definitely need higher power laser and takes longer time to finish, soft wood no need to use higher power laser to complete.

Samples:

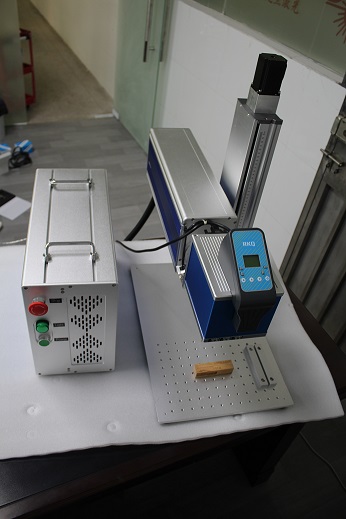

Shipment and package

Certificate

Customer comes to Dotslaser's factory

Unpacking caution

Every marking machine has been rigorously tested at the factory, only qualified product for shipment. When you receive the freight, please check as follows. If you have any questions, please contact the

agent or staff at DOTSLASER.

● Whether there is damage or deformation during transport.

● Confirm that all of the items on the packing list are correct.

● Confirm that the model of the product matches the nameplate(Operating voltage and KVA

number).

● Make sure that all clamps are tight and that there are no foreign objects in the device.

● Confirm the operation buttons, switches are normal.