CO₂ Laser Engraving rubber products

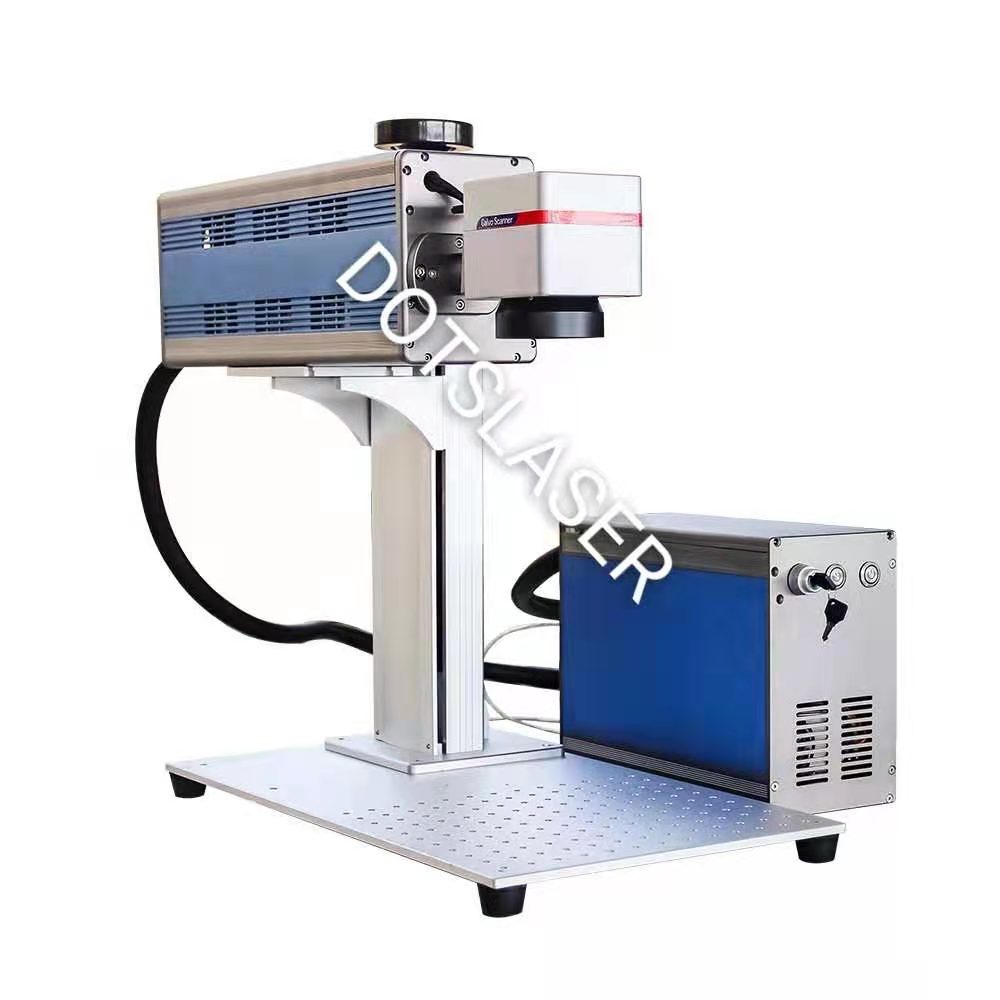

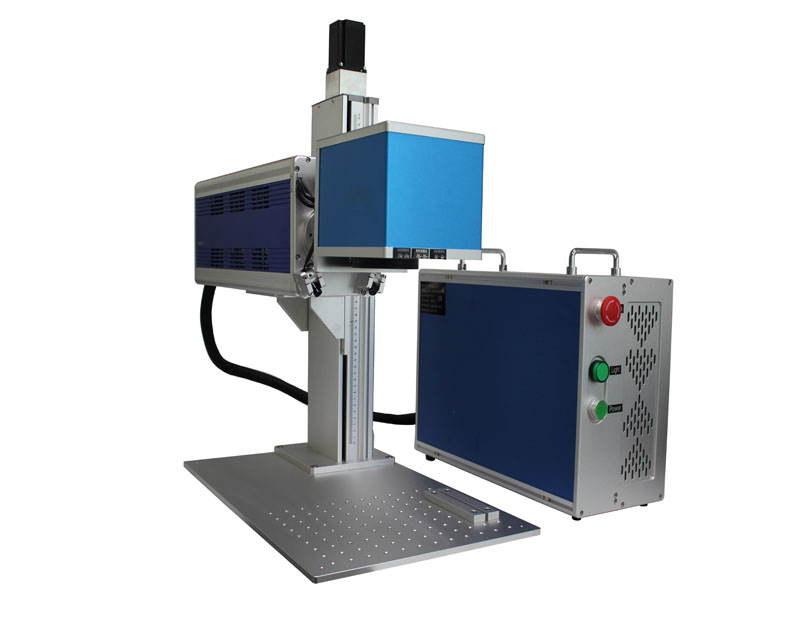

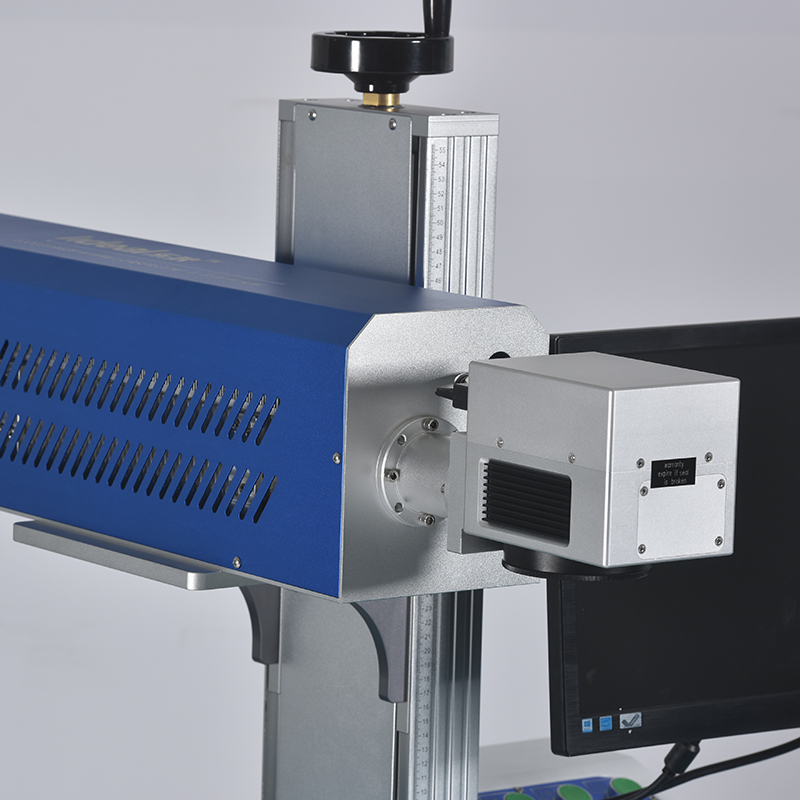

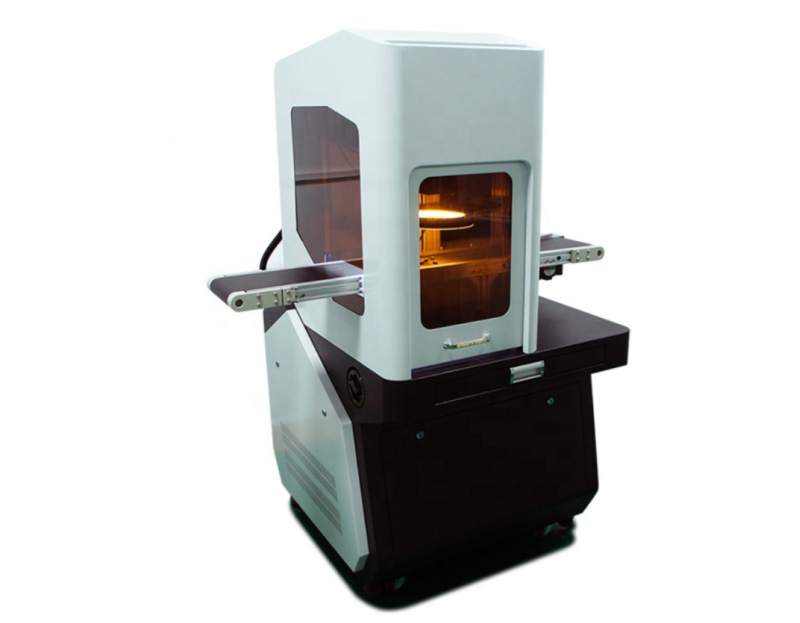

CO2 can well engrave rubber products, it is suitable for nonmetal materials,Dotslaser CO2 laser machine has equipped with high speed galvo scanner and best brand laser source, which can increase machine quality greatly,prolong machine lifetime and save a lot of maintenance cost.

Video shows:

Machine features:

1. High Power Output: The 60W power output allows for deep and precise engravings, even on thicker rubber stamps,this machine equipped with excellent beam quality, high photoelectric conversion efficiency, good performance and can be competent at fine processing.

2. Versatility: CO2 lasers can engrave on a variety of materials, making them suitable for creating custom stamps for different applications, support multiple marking form: Flying Marking,Line Printer, Rotating Marking.Multistage Marking.

3. Engraving Precisely: CO2 lasers offer high precision, ensuring that your engraved designs are sharp and detailed, high precision marking, swift, engraving depth controllable.

4. Fast speed: 60W CO2 lasers can engrave quickly, allowing you to efficiently produce large quantities of stamps,fast engraving speed, save a lot of processing time and labor cost,increase productivity greatly.

Parameter:

NO. | Name | CO2 laser marking machine |

1 | Machine model | DS-LM60 |

2 | Rated output power | 55W/80W |

3 | laser wavelength | 10640 nm |

4 | Laser level | Class 4 |

5 | Repeat accuracy | ±0.01mm |

6 | Min.line width | 0.1mm |

7 | Min.character size | 0.5mm |

8 | Max marking speed | 8000mm/s |

9 | Working area | 100x100mm(standard)/200x200mm/300x300mm |

10 | Cooling | Air cooled |

11 | Working environment temperature range | 5~35 ℃ |

12 | Humidity range of working environment | < 70% No condensation |

13 | working voltage | 220V,50/60Hz |

Applications of Synthetic Rubber:

Drive Couplings

Conveyor Belts

Shoe Soles and Heels

Adhesives

Roll Coverings

Car Tires

Seals

Gaskets

Grommets

SBR pads (Mining equipment)

How to engrave your rubber products properly?

1. Choose the Right Rubber: Select a rubber material that is suitable for CO2 laser machine making. Consider factors such as hardness, durability, and clarity,so that you can engrave your items well.

2. Optimize Laser Settings: Experiment with different laser settings in advance, such as power, speed, and focus, to achieve the best results for your specific rubber material and design.

3. Adjusting correct focus: Right focus is the key that you engrave successfully, adjusting the right focus before you start engraving.

4. Test Your products: Before producing large quantities of rubber products, test a few samples to ensure that the engraving is clear and legible, ensure your products with good quality.

Samples

FAQ

Q: Can your CO2 laser machine cut/engrave rubber?

A: Yes, Dotslaser CO2 laser machine can cut/engrave rubber products. Including natural and some synthetic rubber are well to CO2 lasers,

which allow for clean and precise cuts. It is a preferred and the most common method in many industries for laser cutting rubber.

Q: What materials can be engrave with CO2 laser?

A: CO2 laser marking machine is mainly applicable for many non-metallic materials like leather,textile,film,wood,acrylic,bamboo,board,paper,plastic,stones,

ABS,PVC,PC, and so on. It is used in gifts, advertising decoration, toys, electronic appliances, medicine, food,automobile,packaging, and other industries.

Q: Can you laser engrave silicone rubber?

A: Yes, silicone rubber is laser-friendly. CO2 lasers enable to cut and engrave silicone effectively, making it ideal for personalized items like watch bands or baking mats.

The process yields clean edges and detailed designs.

Q: Can fiber laser cut rubber?

A: Fiber laser is good at metal materials, but when it comes to non-metallic materials like rubber, wood, and acrylic, they aren’t the first choice.

Their wavelength isn’t as well-suited and is not readily absorbed by most types of rubber. For rubber applications, CO2 lasers typically deliver better results.

Q: How strong of a laser do you need to engrave rubber?

A: When it comes to rubber, being softer than metals, doesn't call for intensive laser power. In fact,

a laser cutter ranging between 10 to 50 W is ample to tackle any of the rubber types previously mentioned.

Shipment and package

Certificate