Big Format Laser Engraving On Sport Item

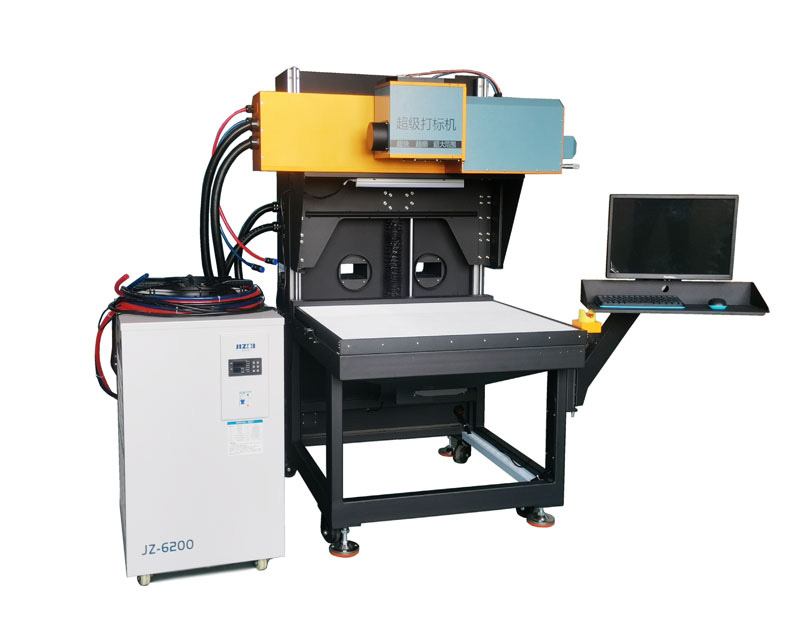

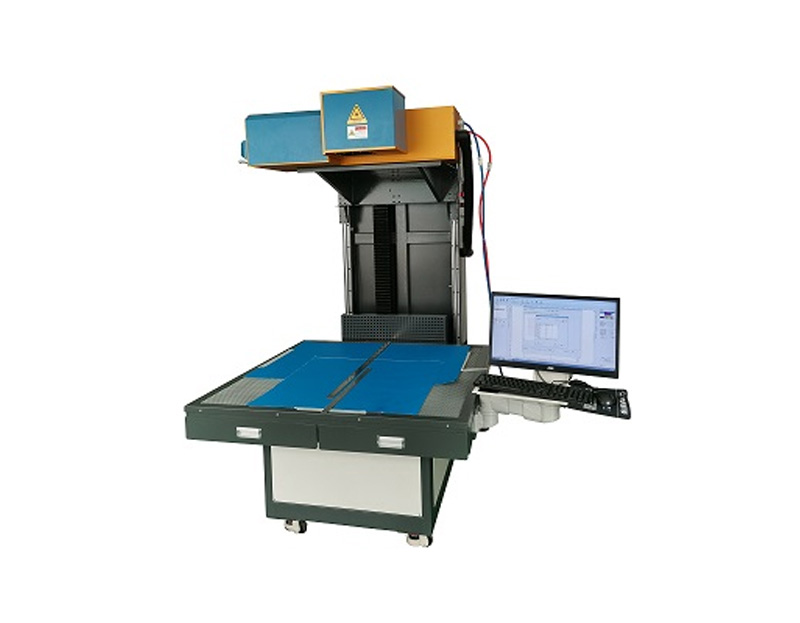

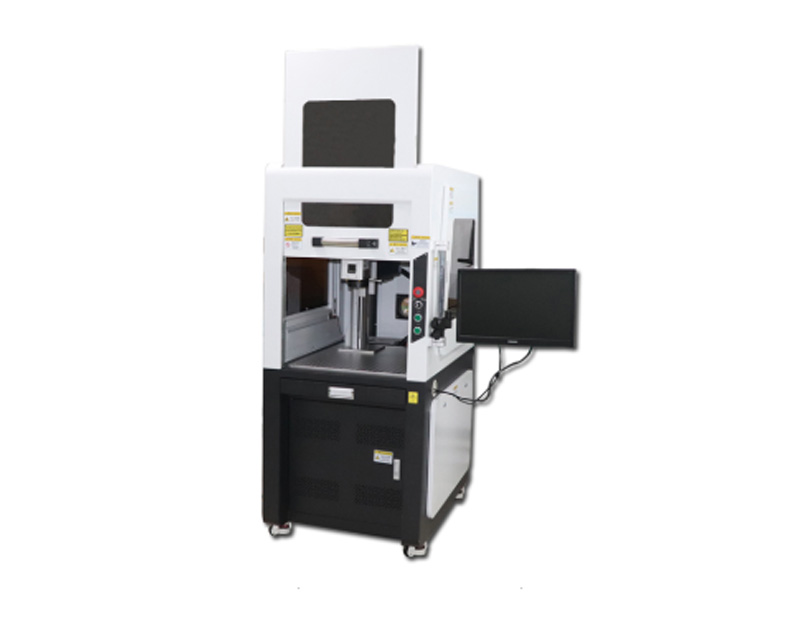

CO2 laser engraving on sport items is common, because its fast engraving speed and high engraving precision, it is suitable for mass productions, this machine can save a lot of processing time and labor cost. Easy to operate,more safe to staff when they're working.

Video shows:

Machine Features

Customers can designs favorite logos to be engraved on sport ware, allowing teams to add a unique touch to uniforms, equipment or merchandise.

Laser engraving provides permanent markings that are durable and long-lasting, ensuring that the design will not fade or wear away over time.

Laser engraving is a highly accurate and precise process that enables intricate designs and details to be added to sport ware with high precision.

Big format laser engraving can be used on a wide variety of materials, including polyester, nylon, and other synthetic fabrics commonly used in sport ware, making it a versatile option for sports teams.

Laser engraving provides a clean and professional appearance to sport ware, enhancing the image of sports teams and organizations.

Strict multi-protection control design is applicable to a wide range of ambient temperatures ensuring the continuous reliable work of the laser marking system.

Parameter

How to engrave your sports items?

Step 1:

In the 3D LASER computer interface of the SUPER marking machine, import or DIY your personalized engraving pattern.

SUPER marking machine 3D software is powerful, compatible with Coreldraw, AutoCAD, Photoshop and other software files; Support PLT, PCX, DXF, BMP, etc., can directly use SHX, TTF library; Support automatic coding, printing serial number, batch number, date, bar code, QR code, automatic jump number, etc

Step 2:

Place the material on the super laser marking and engraving machine, adjust and fix it. Super laser marking and engraving machine is equipped with adsorption platform, which can make the material close to the working plane, prevent the position deviation of the material in the marking process, and the air extraction system can better absorb the dust generated in the cutting process, maintain continuous marking stability, and design humanized.

Step 3:

Design the corresponding parameters in the 3D laser interface, such as length, engraving quantity, whether to flip horizontally and determine cutting.

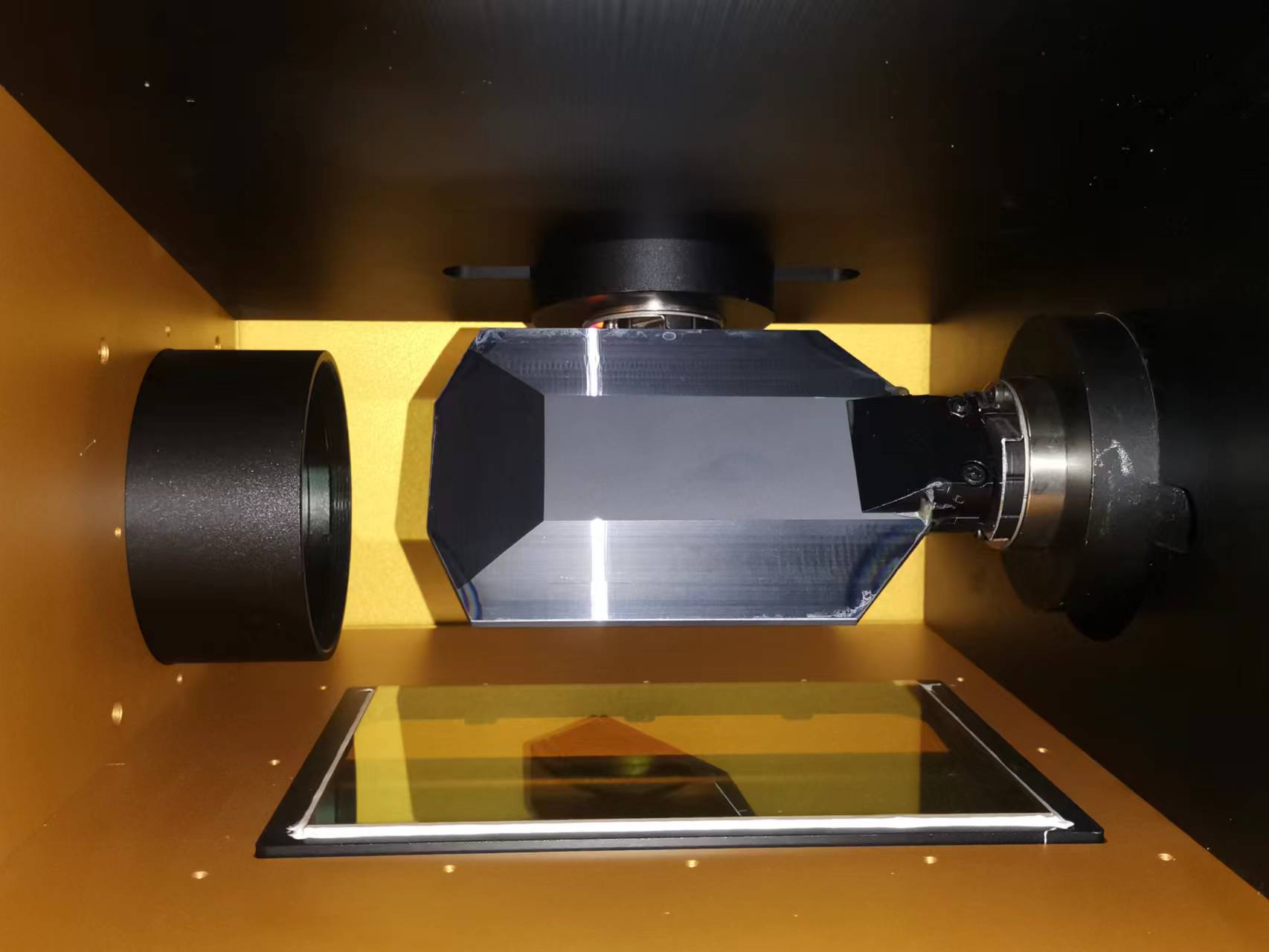

Since the SUPER laser marking machine is equipped with a 2.5-inch super optical focusing system, the focused spot is 50% smaller than the ordinary, and the line width is 0.2mm, so more complex and finer patterns can be cut out. In addition, the British Luxinar brand CO2 RF tube laser is selected as the driving source, which is more stable than the ordinary CO2 glass tube laser, the power output is more stable, the spot is more fine, and the cutting ability is stronger, therefore, the cutting thermal effect is small, greatly reducing the melting edge and the phenomenon of black and yellow, so that the whole effect is more exquisite, greatly improving the quality and grade of the engraving film.

Customer comes to our factory

Shipping and Package