CO2 laser engraving leather products

CO2 laser engraver with a high speed galvo scanner, powerful sensor, so laser beam qulity is stable, this machine also can engrave various materials, such as paper, wood, rubber, plastic,stone,marble,bamboo etc,. It owns impoerted dynamic focus system, constant temperature water cooling unit.

Video shows:

What is leather?

Leather, a timeless and versatile material, adds a touch of sophistication to everything it adorns with laser engraving leather machine. Leather can use for wallets and belts to phone cases and jackets, leather accessories elevate everyday objects into cherished possessions. But what if you could personalize these leather items with intricate designs, logos, or even custom messages?

This passage post delves into the world of laser engraving leather machine, exploring the possibilities this technology unlocks and the benefits it offers for personal and professional use. We'll also introduce the DOTSLASER CO2 Laser, a powerful and user-friendly machine specifically designed for precise and efficient laser engraving on letaher items.

Machine's features:

1. Good laser beam quality

Laser beam quality, M2<1.2, this ensure fast engraving speed (<7000mm/s)and precise engraving.

2. Stable laser wavelength

This CO2 laser marking machine is equipped with powerful laser source and reliable sensor, so output laser wavelength is more stable.

3. Wide applications

CO2 laser marking machine enables engraving various materials,such as wood, paper, leather, bamboo, stone, marble.

Parameter

Laser tube parameters | Max Output Capacity | 250W |

| Nominal Peak Powe | ≥450W | |

| Mode Quality | M2≤1.2 | |

| Duty Cycle Limit | ≤70% | |

| Laser Type | CO2 | |

| Laser Wavelength | 10.6μm | |

Marking performance | Marking Format | Pattern,Word,Bar code,QRcode,Date,Serial Number |

| Marking Character Types | Pattern and words of vectordiagram & bitmap | |

| Marking Area | 400X400-700X700(mmXmm) Adjustable | |

| Marking Depth | 0-5mm (According to the materials) | |

| Marking Speed | <7000mm/s | |

| Min Line Width | 0.3mm(According to the materials) | |

| Min Character | 0.4mm | |

| Repeat Positioning Accuracy | 0.01mm | |

| Machine information | Total Power | <6KW |

| Power Supply | AC220V/50Hz/30A | |

| Cooling Way | Constant temperature water cooling unit | |

| Working Temperature | 15-30℃ | |

| Working Humidity | <75 No condensation | |

| Working Environment | Without dust, without vibration | |

| Machine Packing Size | 1010*1340*1740mm | |

| Control cabinet packing size | 1060*660*1100mm | |

| Chiller packing size | 660*760*1080mm |

Sample

What's the best leather suit for CO2 laser engraving?

Smooth Surface: It provides a clean and even surface for engraving, which allows for clear and precise designs.

High Absorption: The natural fibers absorb the laser's energy effectively, producing a sharp contrast that makes the engraving stand out.

Minimal Warping: Less prone to warping or deforming under the heat of the laser, preserving the shape and quality of the finished product.

What's the functions of CO2 laser engraing?

Incredible Precision: Laser engraving delivers incredibly sharp lines and details, ideal for replicating complex designs or creating delicate patterns.

Permanent Markings: The laser beam creates a permanent mark on the leather, ensuring your personalized design endures for years to come.

Wide applications: CO2 laser machines can engrave a wide range of leather types, from smooth finishes to textured surfaces, offering vast creative possibilities.

Fast and Efficient: Laser engraving is a rapid process, allowing you to complete projects quickly and efficiently.

Clean and Repeatable Results: The laser beam minimizes dust and debris, producing clean and consistent engravings every time.

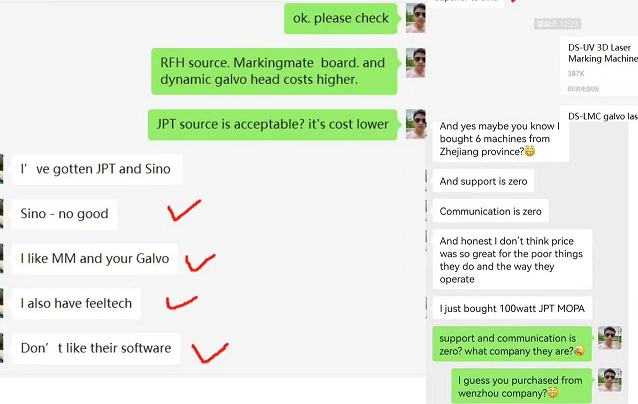

Customer's feedback

Process of laser engraving leather?

1. Choose the Right Leather

Opt for vegetable-tanned leather, which responds well to laser engraving by producing crisp, clear designs. Avoid chrome-tanned leather, as it can release harmful fumes during engraving and may not yield the same quality results.

2. Test Settings Before Engraving

Always conduct a test run on a scrap piece of the same leather. This allows you to adjust the laser's speed and power settings to find the optimal balance for clarity without burning the leather excessively.

3. Clean the Leather Surface

Ensure the leather is clean and free from oils or dirt before engraving. Use a soft cloth slightly dampened with water or a mild leather cleaner. A clean surface ensures uniform engraving and reduces the risk of unexpected marks.

4. Use Low to Medium Power Settings

Starting with lower power settings helps prevent burning the leather. Gradually increase power as needed, based on your test engravings. This is especially crucial for thin or delicate leather.

5. Focus on the Laser Precisely

Proper focusing of the laser is essential for sharp engravings. An out-of-focus laser can result in blurry or uneven designs. Refer to your machine's manual for instructions on how to adjust the focus correctly.

6. Control the Speed

Adjusting the speed of the laser can impact the depth and darkness of the engraving. A slower speed results in a darker engrave, while a faster speed is better for lighter engravings. Find the right speed that works for your specific leather type and desired outcome.

7. Protect the Leather from Excess Heat

Applying a thin layer of masking tape over the engraving area can help protect the leather from excess heat and reduce flare-ups. This technique also helps in achieving cleaner engraving lines.

8. Keep the Laser Lens Clean

Regularly clean the lens of your laser engraver to ensure it's free from dust and debris. A clean lens provides a more focused and effective beam, crucial for detailed work on leather.

9. Utilize Air Assist

If your machine is equipped with an air assist feature, use it to blow away smoke and debris during the engraving process. This helps in preventing the smoke from staining the leather around the engraved area.

10. Post-Engraving Care

After engraving, gently clean the leather with a dry cloth to remove any debris. If necessary, lightly dampen the cloth with water for cleaning but avoid using chemical cleaners. Apply a leather conditioner to keep the engraved area supple and protect the leather from drying out.

Machine's components

Shipment and package

Certificate

FAQ

Q: How can we guarantee the machine quality?

A: We will conduct pre-production samples before mass production, final test machine again before shipment.

Q: How can i operate the machine correctly?

We will send you a video to teach you how to use the machine, if you still have problems with machine, our technical operator enables chatting with you on phone or have a video call with you.

Q: How does the package?

A: Dotslaser provides 3 layers package. For the outside, we adopt wood craft case. In the middle.the machine is covered by foam, to protect the machine from shaking. For the inside laser machine, the machine is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and ourshipping agent have full experienced in safe transportation. We have exported to 100 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How to install and run the machine?

A:Our worker will install all the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine 95% customers can learn by themselves.

Q: How can i do if the machine goes wrong?

A: lf confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we

can to solve it for you.