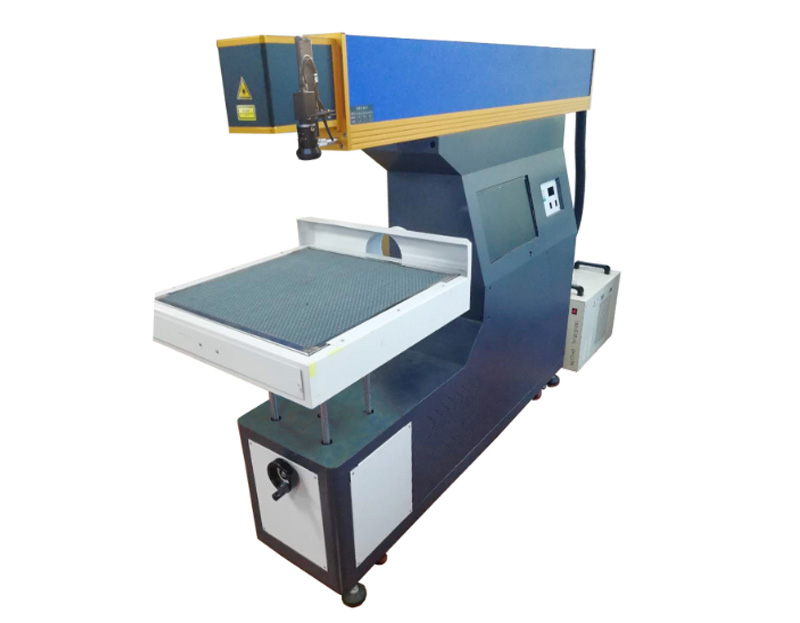

CO2 Laser Engraving On Packing Box

CO2 laser marking machines are used for engraving on packaging boxes to create clear and permanent markings. The machine works by using a high-power laser beam to etch on the surface of the material. It is ideal for use on various materials such as cardboard boxes, wooden boxes, plastics, and paper.The advantages of using CO2 laser marking machines on packaging boxes are numerous. Firstly, it allows for precise and detailed engravings, with a non-contact process that ensures high accuracy and consistency. Secondly, the laser markings are permanent, meaning that they stay intact even after exposure to pressure, water, or heat.

01/

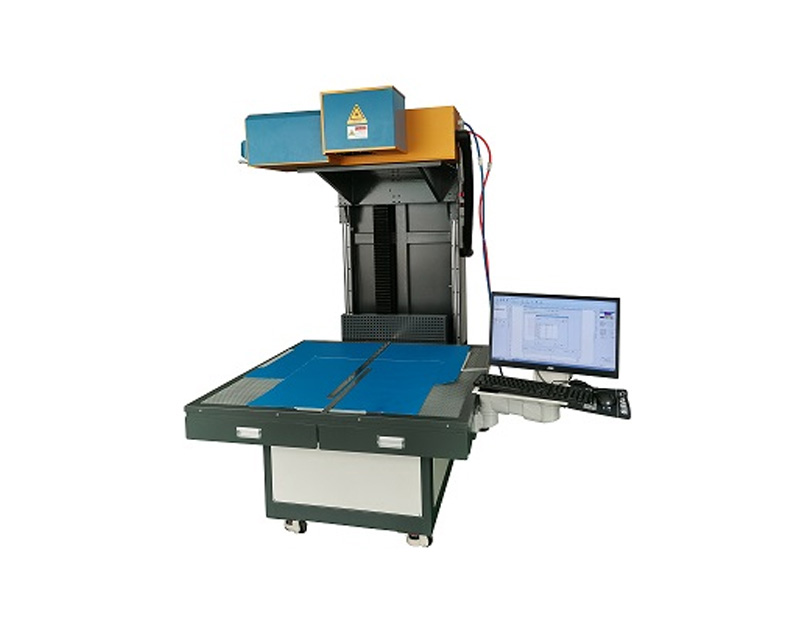

Wide working area

The three dimension focus system make the machine has bigger working area and finer optical spot diameter.The maximum marking area of the customized system can reach 2mX 2m.

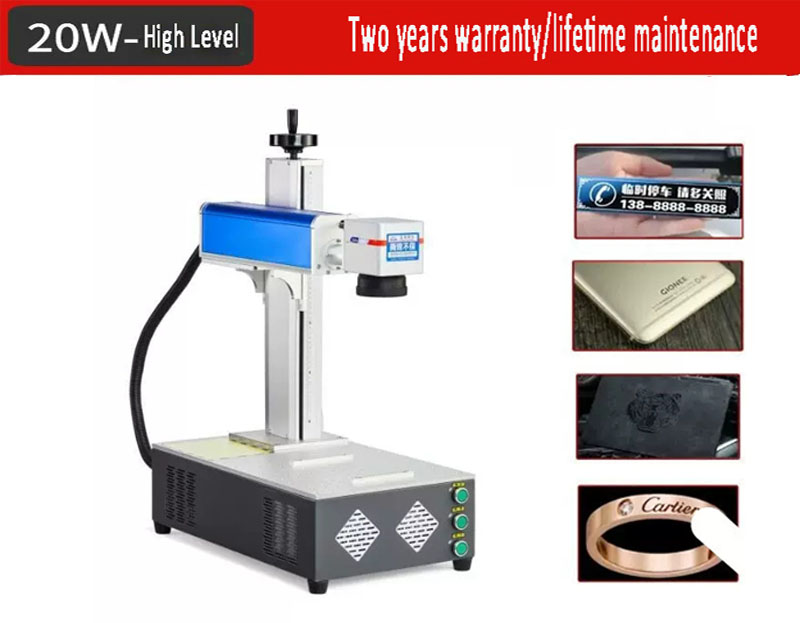

02/ Engraving efficiently

It has smaller focusing spot and higher energy density which are suitable forfiner cutting, punching and engraving.

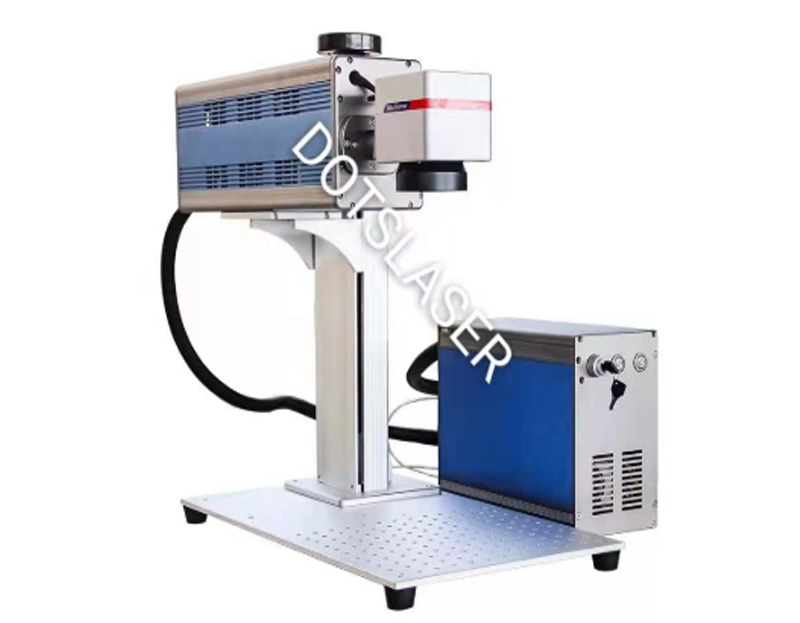

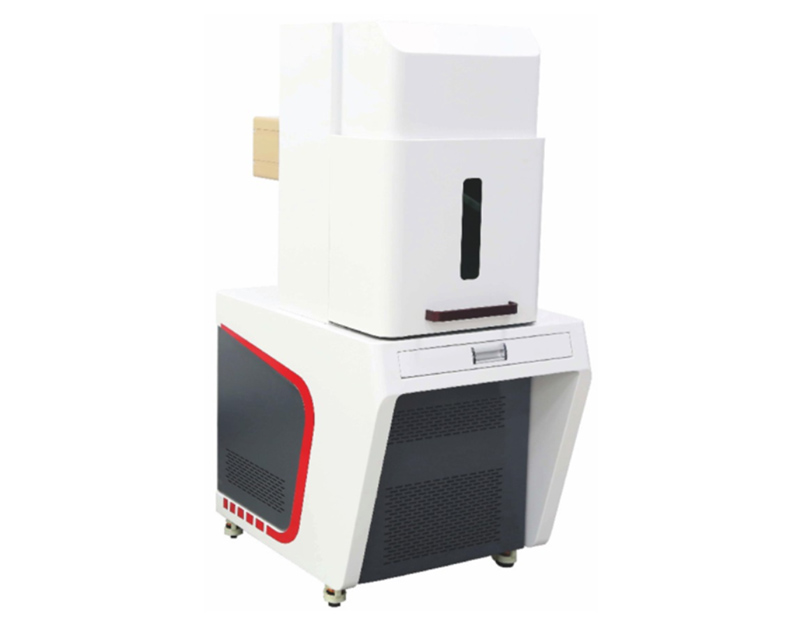

The Fully closed free-maintenance laser optical system is ready to use after installation without adjustment.

It's performance ensure smooth sharp cutting edge. The processing result is more average, without too high ortoo low energy injected in partial area.

The system is designed with external double-circulation industrial cooling water system, which is convenient for users to choose according to the place of use and conducive to the protection of work environment.

Strict multi-protection control design is applicable to a wide range of ambient temperatures ensuring the continuous reliable work of the laser marking system.

Parameter

Three Axis Dynamic CO2 Laser Marking Machine is widely suitable for the industries, such as Heat Transfer film (paillette, TPU materials, Reflective transfer film, etc.), leather, wooden box, paper card, clothes denim, illuminator,Mobile communications, mould, precision machinery, IT Digital shell, Military aviation components, handicrafts, Advertisement decoration, etc.

How to make a packing box with laser engraver?

Card stock is a very general and popular material, which can be used for laser cutting and engraving. This sample project features card stock that we carve and cut to create custom product packaging. By adjusting the speed, power and frequency settings of the laser, the operator can etch text, cut shapes, and even create perfect perforation lines for folding and assembly.

Laser technology optimized packaging production

Laser material processing started a change in industry. It brings quantitative improvements, such as the improvement of production speed, and quality improvements, such as the possibility of creating high value-added customized products, even on a small scale. The packaging industry immediately recognized that the use of lasers can provide unlimited possibilities for innovation.

Packaging is a basic aspect of most manufacturing industries, and laser technology occupies a strong position in this growing market. Laser strengthens and improves the characteristics of packaging materials to help them better perform their expected functions.

Samples of laser engraving packing boxes

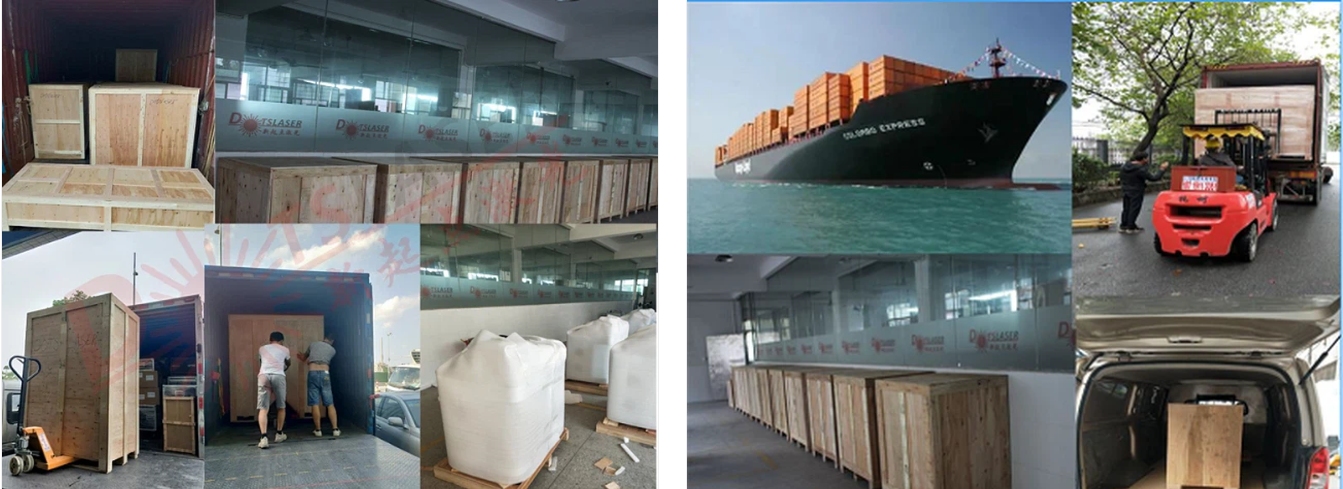

Shipping and package

Certificate