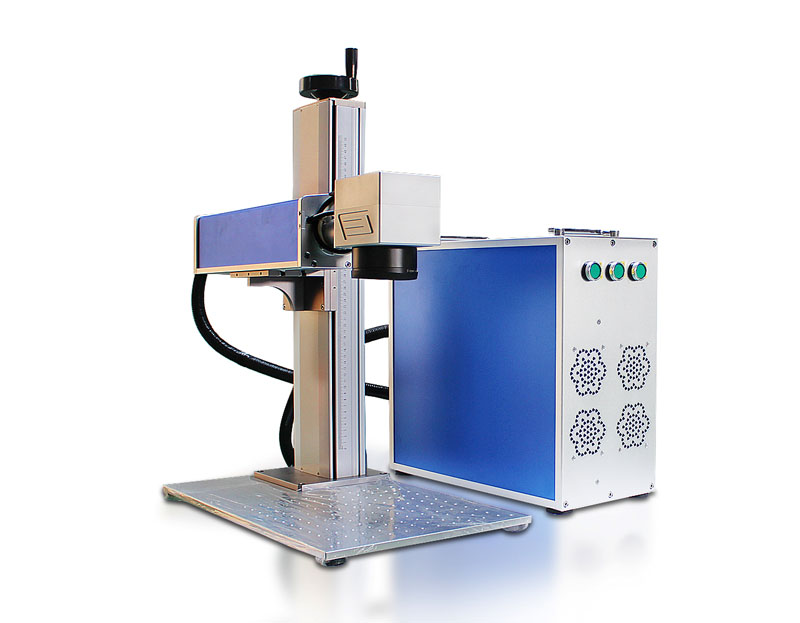

CO2 laser marking for cardboard

CO2 laser marking mahine often use on paper decorations,such as advertising, in production of packaging and various printed products, and even for technical purposes,using laser machine processing speed and productivity is greatly higher than conventional techniques. This machine equipped with high speed galvo scanner, which can create high quality products by more precisely engraving every find edge.

Video shows:

Machine features:

The three dimension focus system make the large working area and finer optical spot diameter,the maximum customized area can reach 2mx2m, which is suitable for mass production.

2. This machine equipped with smaller focusing spot and higher energy density which are suitable for finer cutting, punching and engraving.

3. CO2 laser machine with its high precision and high speed marking/cutting performance ensure smooth sharp cutting edge. During engraving,the laser power is more average, without too high or too low energy injected in partial area, it can't cause damage to materials and products.

4. Strict multi-protection control design is applicable to a wide range of ambient temperatures ensuring the continuous reliable work of the laser marking system, good machine setting ensure safe environment to workers.

Which cardboard and paper are suitable for laser engraving?

Paper in different weights and thicknesses can be cut and often also engraved. Grey paperboard can be cut, marked and engraved with speed and precision. White cardboard can be cut and engraved. On thicker types laser residue is visible after cutting.

1. Craft, matte, chalk-coated, designer, offset, newsprint, coated or embossed paper;

2. Standard cardboard, cardboard of various densities, packaging, printing, designer, chipboard, beer, combined cardboard;

3. Corrugated cardboard, including multilayer and laminated;

4. Foam board, including self-adhesive.

Machine parameter:

Laser tube parameters | Max Output Capacity | 250W |

| Nominal Peak Powe | ≥450W | |

| Mode Quality | M2≤1.2 | |

| Duty Cycle Limit | ≤70% | |

| Laser Type | CO2 | |

| Laser Wavelength | 10.6μm | |

Marking performance | Marking Format | Pattern,Word,Bar code,QRcode,Date,Serial Number |

| Marking Character Types | Pattern and words of vectordiagram & bitmap | |

| Marking Area | 400X400-700X700(mmXmm) Adjustable | |

| Marking Depth | 0-5mm (According to the materials) | |

| Marking Speed | <7000mm/s | |

| Min Line Width | 0.3mm(According to the materials) | |

| Min Character | 0.4mm | |

| Repeat Positioning Accuracy | 0.01mm | |

| Machine information | Total Power | <6KW |

| Power Supply | AC220V/50Hz/30A | |

| Cooling Way | Constant temperature water cooling unit | |

| Working Temperature | 15-30℃ | |

| Working Humidity | <75 No condensation | |

| Working Environment | Without dust, without vibration | |

| Machine Packing Size | 1010*1340*1740mm | |

| Control cabinet packing size | 1060*660*1100mm | |

| Chiller packing size | 660*760*1080mm |

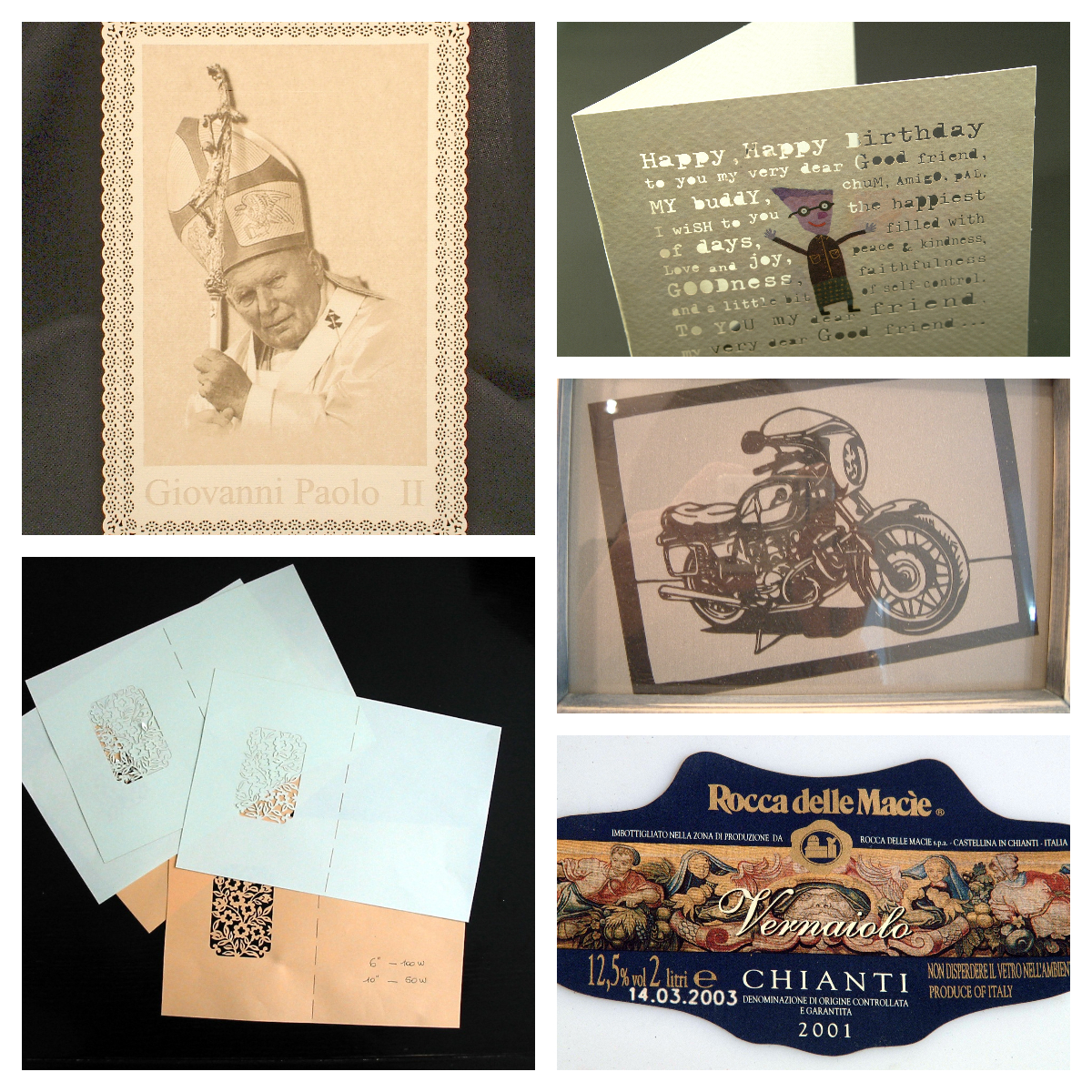

Sample shows:

Cradboard information:

Cost-effective materials:

Compared with other materials, cardboard has a huge advantage of low price. As a kind of raw material, due to its extensive use in the global packaging industry, its cost is low.

Cardboard is light in weight, faster in transportation and lower in cost. In terms of laser cutting, the unique internal structure of corrugated cardboard means that it can be cut quickly

which makes cardboard one of the materials with the lowest cost of laser cutting time.

Different Types Of Cardboard:

Cardboard is a general term for thick paper products, which has greater thickness and superior durability or other specific mechanical properties of paper; such as foldability, rigidity, and impact resistance.

The structure can range from a thick board called cardboard to a corrugated fiberboard made of multiple corrugated and flat layers.

Cardboard applications:

Cradboard is a material with reasinable price and versatile, making it ideal for many different applications, from advertising to packaging, arts and crafts, special wedding invitations and more. Common cardboard laser engraving/cutting applications created from laser cut shapes include:

Arts and crafts

Custom boxes and packaging

Business cards and other professional supplies

Signs and displays

Greeting card

Invitation

Table card

Shipment and package

Daily maintenance

● After finishing work, make sure the floor is clean. Then clean the machine including the surface

of the machine, the case of the optical system, the surface of the monitor, the work table, and so on.

● Please turn off each part and main power supply when they are clean.

● Check the lens regularly for dust. When it's clean, use the cotton wool with greater than 95%

medical grade alcohol to wipe clockwise from the center of the lens. When you need to move the machine to avoid bumps.

Check the connection cable according to the cable list.

Unpacking caution

Every marking machine has been rigorously tested at the factory, only qualified product for shipment. When you receive the freight, please check as follows.

If you have any questions, please contact the agent or staff at DOTSLASER.

● Whether there is damage or deformation during transport.

● Confirm that all of the items on the packing list are correct.

● Confirm that the model of the product matches the nameplate(Operating voltage and KVA

number).

● Make sure that all clamps are tight and that there are no foreign objects in the device.

● Confirm the operation buttons, switches are normal.