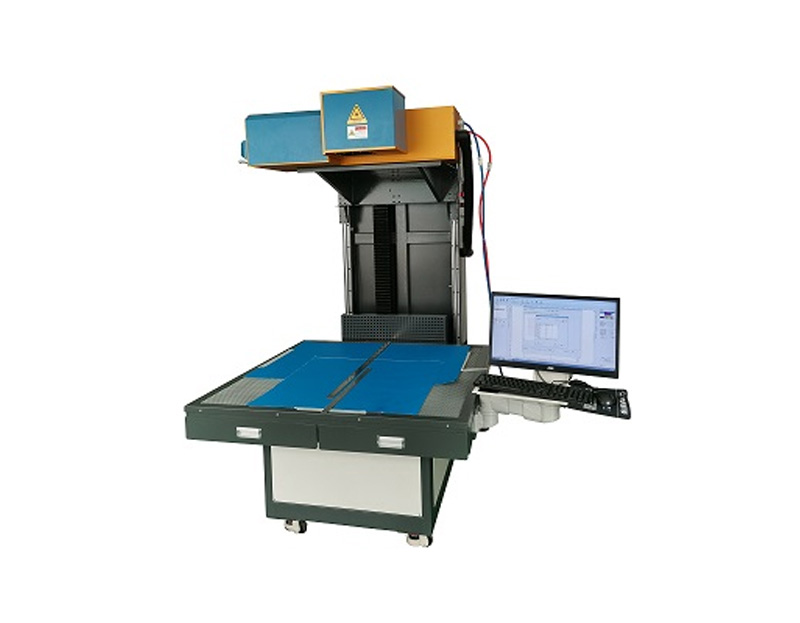

CO2 Laser Marking Machine Burn Clothes Crafts

CO2 Laser marking machine is a high-tech tool that can precisely engrave and cut various materials. When it comes to burning clothes crafts, CO2 laser marking machines are the perfect choice as they can easily create customized patterns and designs on fabrics. The laser beam is extremely precise and does not cause any damage to the cloth. Additionally, the process is fast and efficient, making it perfect for mass production. Moreover, the CO2 laser marking machine can also be used to engrave other materials such as wood, plastic, and metal. This laser technology is excellent for creating personalized gifts, awards, and promotional items.

Video shows:

Machine Features

The CO2 Laser marking machine has three dimension focus system make the machine has bigger working area and finer optical spot diameter.This means that you can create intricate designs and patterns with excellent accuracy and detail.

02/Versatility

The CO2 Laser marking with smaller focusing spot and higher energy density which are suitable forfiner cutting, punching and engraving.It can mark textiles, leather, wood, glass, and plastics.

03/Durability

The CO2 laser marking machine creates permanent markings on clothes crafts. This makes the designs and patterns more durable and longer-lasting, which is increase the using rage of clothing.

04/High precision and high speed marking/cutting

Marking performance ensure smooth sharp cutting edge. The processing result is more average, without too high or too low energy injected in partial area.

05/Environmentally friendly

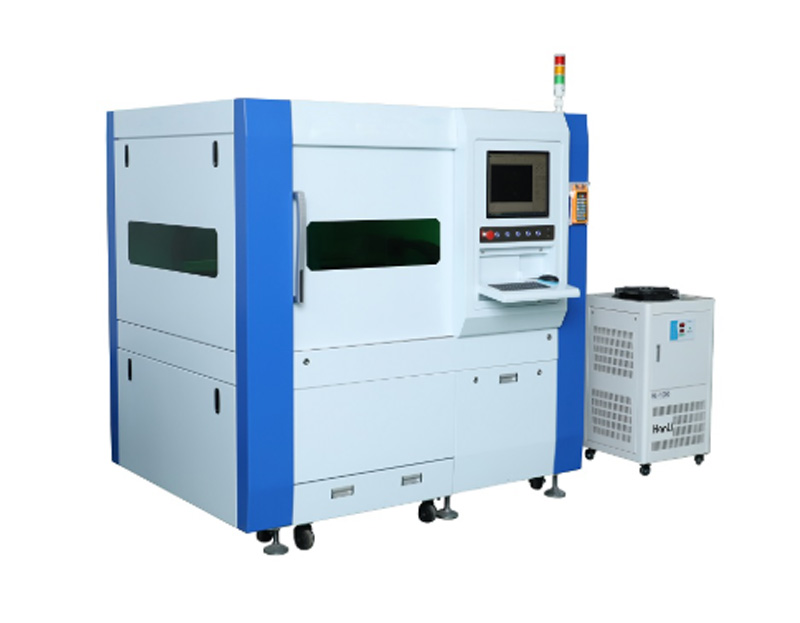

The system is designed with external double-circulation industrial cooling water system,The CO2 Laser marking machine uses a non-toxic and environmentally friendly marking method. The whole machine runs more stable and has lower power consumption.

Parameter

Three Axis Dynamic CO2 Laser Marking Machine is widely suitable for the industries, such as Heat Transfer film (Paillette, TPU materials, Reflective transfer film, etc.), leather, wooden box, paper card, clothes denim, illuminator,Mobile communications, mould, precision machinery, IT Digital shell, Military aviation components, handicrafts, Advertisement decoration, etc.

As an all-new process, there are several applications of laser in apparel industry. Laser engraving and cutting technologies now being widely applied in many garment industries, fabric production units, other textile and leather industries. In synthetic fabrics, laser cutting produces well-finished edges as the laser melts and fuses the edge, which avoids the problem of fraying produced by conventional knife cutters. Furthermore, use of laser cutting is increasingly used for leather due to the precision of cut components. In fashion accessories, laser cutting can be used to produce new and unusual designs.

In laser cutting a laser is used to cut the fabric into the desired pattern shapes. A very fine laser is focused on to the fabric surface, which increases the temperature substantially and cutting takes place due to vaporization. Normally CO2 lasers are used for cutting of fabric. Unlike traditional knife cutting, the laser beam does not become blunt and does not require sharpening.

Cloths

Shipment and Package