Laser Engraving On Wood Products

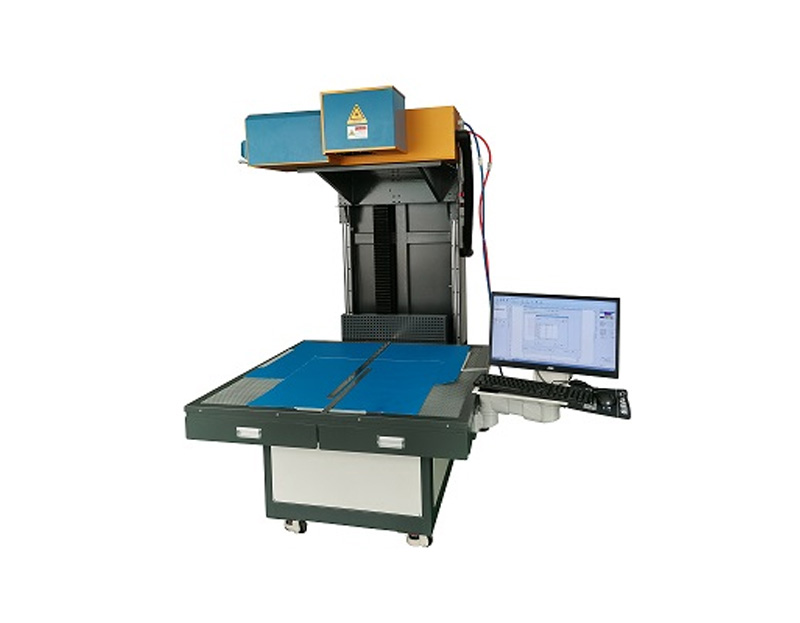

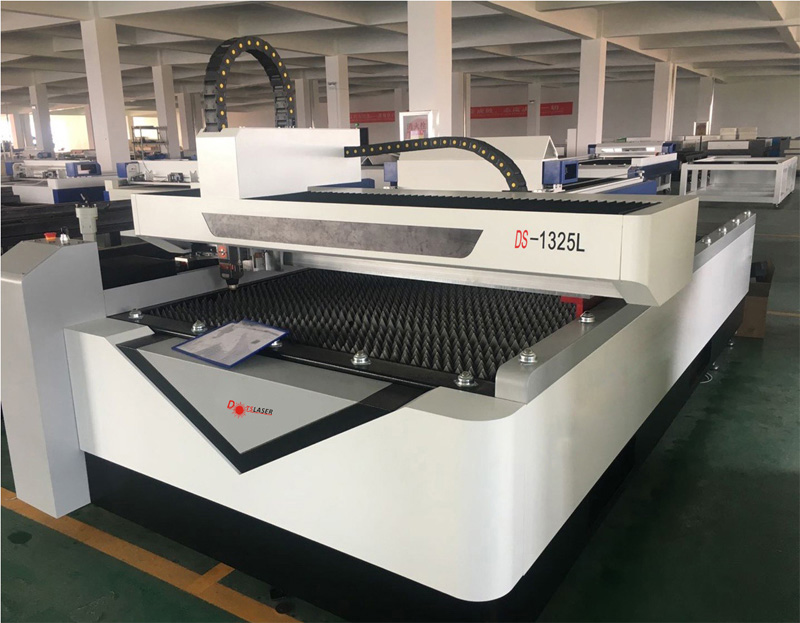

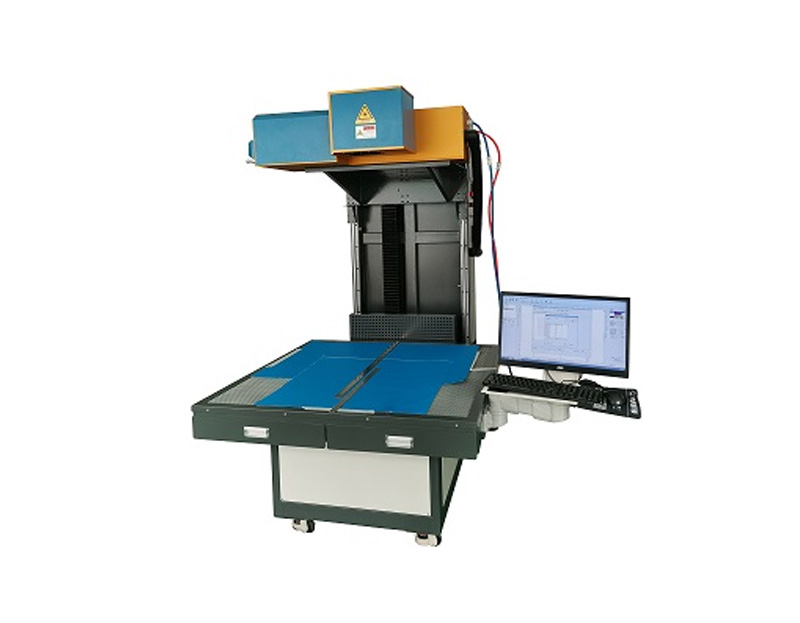

CO2 laser engraver has three axis dynamic, CO2 Laser Marking Machine is widely suitable for the industries, such as Heat Transfer film (paillette, TPU materials, Reflective transfer film, etc.), leather, wooden box, paper card, clothes denim, illuminator,Mobile communications, mould, precision machinery, IT Digital shell, Militaryaviation components, handicrafts, Advertisement decoration

Video shows:

Machine Features:

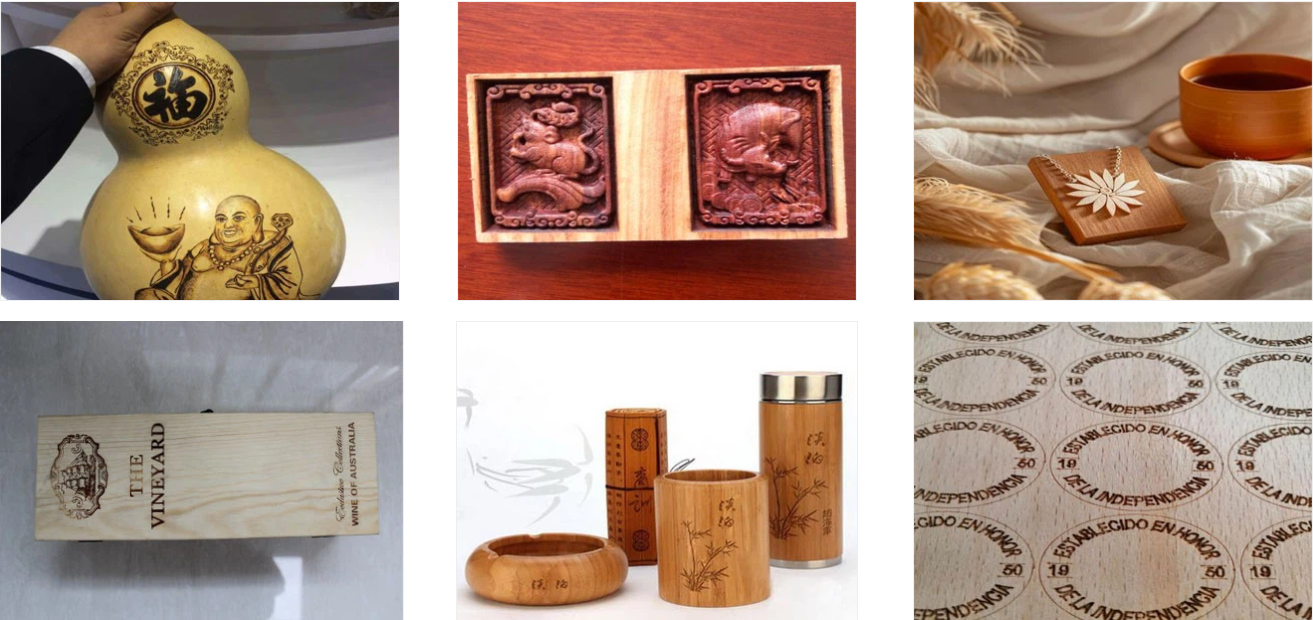

Our this type of machine can produce incredibly precise designs. Cpmpare with traditional woodworking methods, laser technology allows for detailed cuts and intricate designs with minimal error.

Laser technology makes engraving on wood products faster and more efficient. The laser can also be programmed to engrave multiple pieces with identical designs one by one, saving time and effort.

This machine is suitable for engraving wide range of wood products, including furniture, decorations, and signs. They can also be adjusted to work on different types of woods, from softwoods to hardwoods.

Engraved designs produced by laser technology are highly durable and long-lasting. This is because the laser burns the design into the wood, creating a permanent bond that won't fade or wear away over time.

Laser engraving machines allow for complete customization of wood products. Designs can be created using software programs, and personalized messages or images can be added to create unique products.

Laser engraving machine with fast engraving speed ,our factory offers basic free services and repairs,it can save much processing time and labor cost.

Machine's Parameter

Three Axis Dynamic CO2 Laser Marking Machine is widely suitable for the industries, such as Heat Transfer film (paillette, TPU materials, Reflective transfer film, etc.), leather, wooden box, paper card, clothes denim, illuminator,Mobile communications, mould, precision machinery, IT Digital shell, Military aviation components, handicrafts, Advertisement decoration, etc.

● Natural Wood (unprocessed with chemicals)

●Softwood/Hardwood

●Birch (easy to find, readily available)

●Pine (great choice for laser cutting)

●Cedar (soft, straight grain, pleasant smell)

●Redwood (reddish tint, resistant to moisture)

●Ash (hard to find, finishes well)

●Birch (readily available)

●Cherry (popular for furniture)

●Mahogany (works great with lasers, hard to find)

●Oak (beautiful grain, easy to work with)

●Walnut (works well with laser, expensive and rare)

●Cork (naturally buoyant, elastic and fire resistant)

●Balsa (very lightweight, inexpensive, great for laser cutting)

●Bamboo (technically not wood, but widely used in cutting boards which are great for engraving but difficult to cut with good results)

Samples

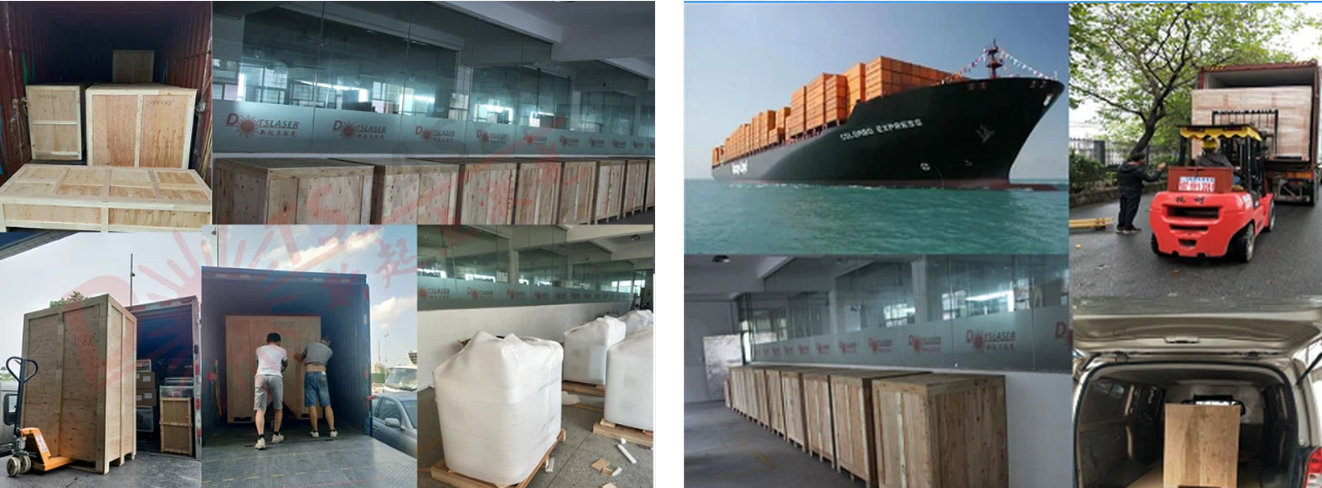

Shipping and Package

1. Quality assurance and after-sales service

The warranty period of the equipment shall be 12 months since the equipment be used by the customers, the installation and debugging is completed and the equipment is accepted by the demander. Dotslaser attaches great importance to the after-sales service work of the product, once the product is delivered to the user, the company immediately established the user after-sales service file, and regularly track the user's product use status, solve and answer all the problems of the user, received the user's notification information about the equipment failure, the company's workers can make a rapid response within 2 hours. If the telephone guidance is difficult to troubleshoot, our company's technical staff can arrive at the customer site within 24 hours to provide support.

2. Installation and debugging

Before machine installation, our factory will offer you a basic structure installation file,the good need 2 weeks delivery to you there , the engineers of Dotslaser will arrive at your site and inspect the machine again. Comfirm all the conditions meet the installation and commissioning requirements of the equipment, the equipment will transport in time. The installation and commissioning time of the equipment is about five working days, the first three days are connected to the use of the system, and the system is operational after the service project. The engineer will train qualified operators on basic maintenance procedures and general operating characteristics of the equipment in the next two days

3. Service support

If there has any problem with any part of the system during the warranty period, Dotslaser well-trained service engineers are ready to provide cellphone call or begin on-site service,if the machine has any problem during the warranty period,please contact us directly !

Unpacking Caution

Every marking machine has been rigorously tested at the factory, only qualified product for shipment. When you receive the freight, please check as follows. If you have any questions, please contact the agent or staff at DOTSLASER.

● Whether there is damage or deformation during transport.

● Confirm that all of the items on the packing list are correct.

● Confirm that the model of the product matches the nameplate(Operating voltage and KVA number).

● Make sure that all clamps are tight and that there are no foreign objects in the device.

● Confirm the operation buttons, switches are normal.