Leather CO2 laser engraving

Laser marking machine offers precise and perfect engraving on leather that can't be achieved through other engraving methods. There are a variety of personalized leather items, such as wallets, bags, belts, hat patches, keychains, and journals, can be made through laser engraving.

Video shows:

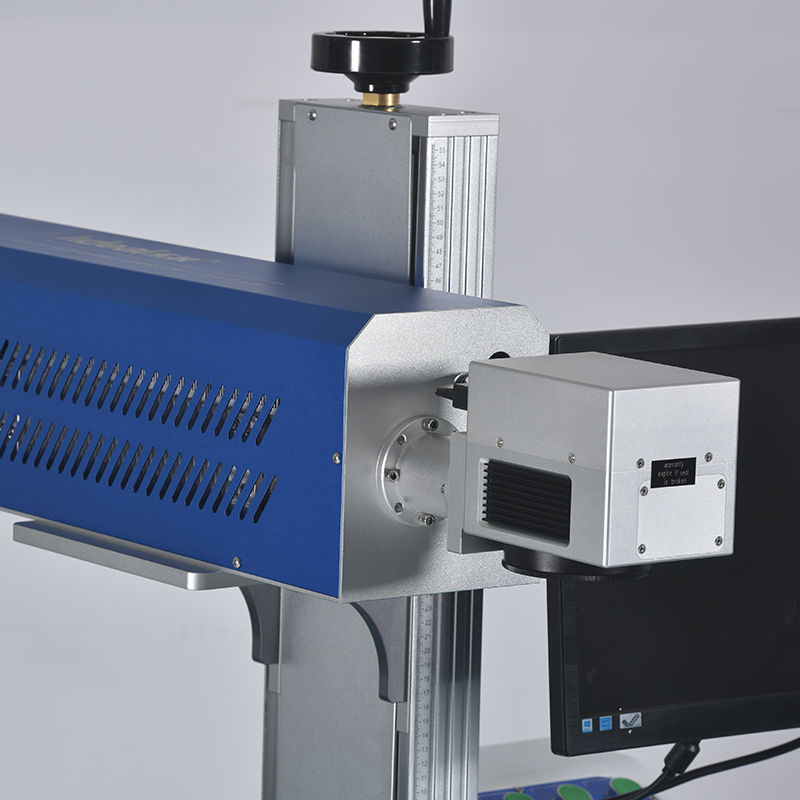

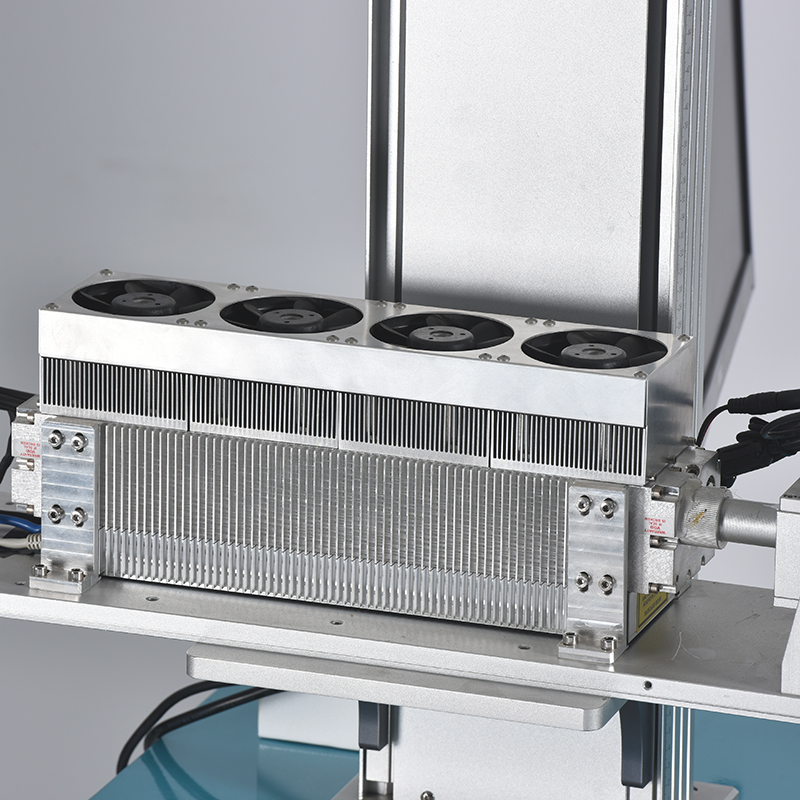

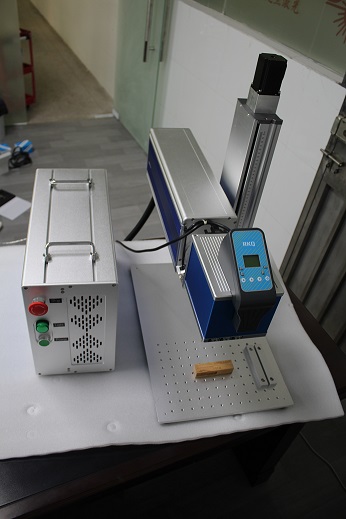

Machine features:

1. Versatile: Suitable for various nonmetal materials such as plastic, acrylic, wood, bamboo, paper, stone,and leather, with clear markings and good marking effects.

2. Powerful control system: it can optimize a variety of data according to different processes and support multi-language one-key switching, it meets the application process requirements of most industries in the market .

3. Special techniques: Using high-quality light source, good spot quality, uniform optical power density, stable output optical power, it has the characteristics of no light leakage, anti-high reflection, etc., which meets the mainstream market application requirements.

4. Permanent marking: marking effect won't fade in the harsh environment(low temperature/overheat temperture/often touching)

What types of laser can engrave leather well?

CO2 laser engravers are considered the best option for engraving leather. They are designed for a wide range of materials, especially the non-metallic, including leather, wood, acrylic, stone, paper, glass, rubber, fabric, and more. CO2 laser engravers are suitable for small business owners looking to diversify their offerings with different materials and increase efficiency.

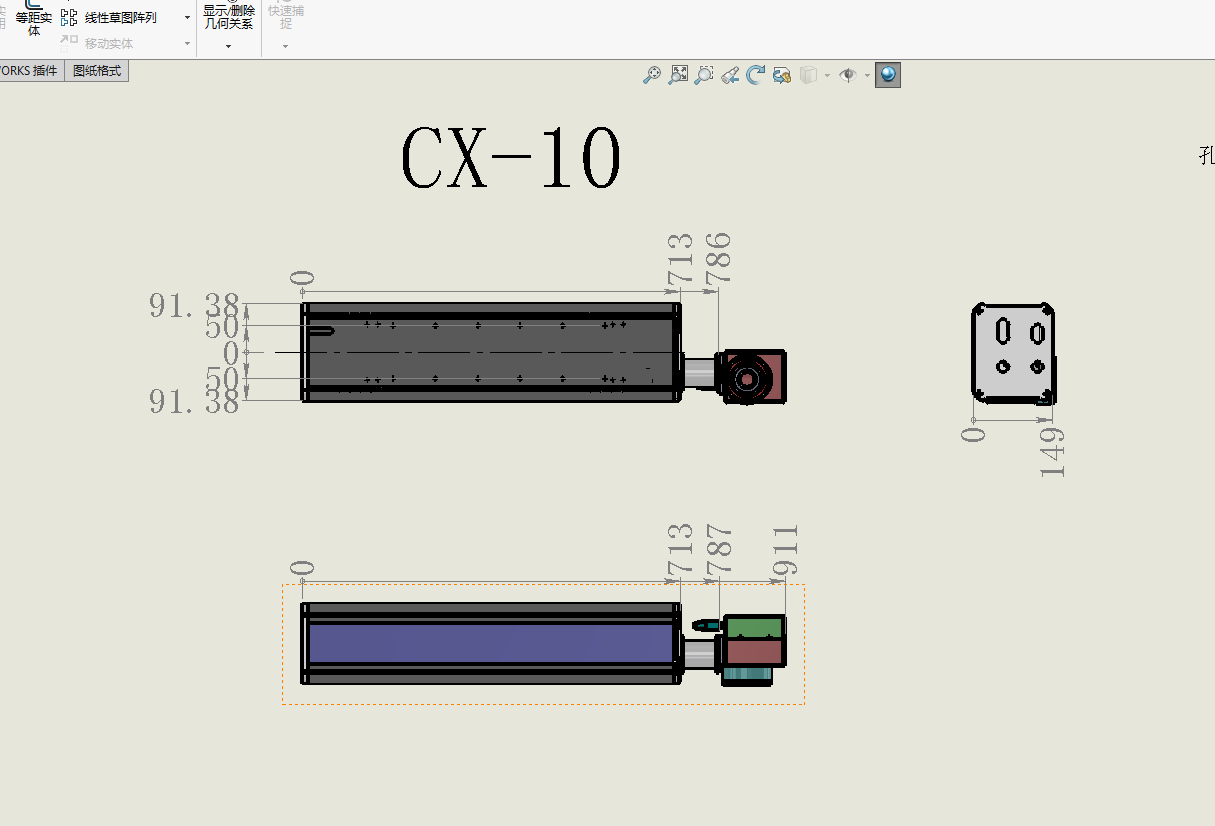

Parameters:

NO. | Name | CO2 laser marking machine |

1 | Machine model | DS-LM60 |

2 | Rated output power | 55W/80W |

3 | laser wavelength | 10640 nm |

4 | Laser level | Class 4 |

5 | Repeat accuracy | ±0.01mm |

6 | Min.line width | 0.1mm |

7 | Min.character size | 0.5mm |

8 | Max marking speed | 8000mm/s |

9 | Working area | 100x100mm(standard)/200x200mm/300x300mm |

10 | Cooling | Air cooled |

11 | Working environment temperature range | 5~35 ℃ |

12 | Humidity range of working environment | < 70% No condensation |

13 | working voltage | 220V,50/60Hz |

What types of leathers best for laser engraving?

1. Natural leather is best for laser engraving,this leather is obtained from animals. Most of such leather is excellent for laser engraving. You can use leather made from cowhide, lambskin, deerskin, sheepskin, etc.But in order to protect wild animals,we more recommend other leathers.

2. Full grain leather is the strongest and most durable grade of leather available. It retains the maximum thickness, oil absorption, and natural grains from the original outer layer of the animal hide. The full-grain leather is the highest quality leather you can find.

3. Top grain leather is the second highest grade of leather and has the outermost layer of hide removed. Top grain leather which is the second-best quality.

4. Corrected grain is leather from the upper part of the hide where there the surface has been polished or buffed. Then there is corrected grain leather which is altered leather, and the last one is the bonded leather which is made from the leftovers.

All these types of leather can be used for laser engraving. But you need to run the laser power and speed settings test before you start.

Samples:

Shipment and package

Tips for laser engraving leather:

If you want to engrave well leather products, there are some tips for you:

Choose the right types of leather,thin or thick leather is different in engraving

Adjusting the correct power and speed settings, it is better to run a power-speed test on a piece of scrap leather and then choose the optimal settings. It prevents the wastage of material and precious time.

The focus of the laser machine is very important. Even if your settings are correct, there is no guarantee of good results if the focus is not correctly adjusted. Make sure the focus is correctly calibrated before engraving.

Clean the leather object after engraving. Remove the debris and particles. You can also polish leather if needed.

After sales services:

DOTSLASER has specially set up a marketing management center, with more than 100 offices across the country, to provide customers with comprehensive pre-sale, in-sale and after-sale support and services. Where there are new starting point laser products, there is the high-quality service of new starting point company!

1. Free technical consultation, software upgrade and other services;

2. The response time of customer service is within 24 hours;

3. Provide maintenance services for life.

Certificate