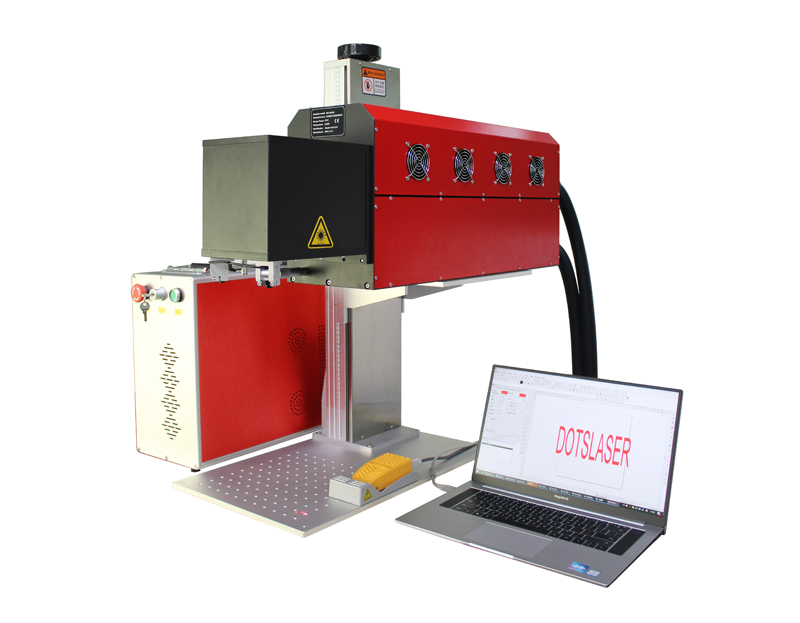

100W Fiber laser cleaning machine

The 100W fiber laser cleaner has wide range applications, such as removing contaminants, rust, paint, and other unwanted substances from surfaces,The laser beam is generated by a laser generator and directed through an in-line cable to a handheld device that focuses the beam onto the surface to be cleaned. Handheld laser cleaners are used in a variety of industries, including automotive, aerospace, and manufacturing. In these industries, the cleanliness of machinery and equipment is critical to maintaining efficiency and preventing damage. It is also used in restoration projects such as cleaning historic buildings and monuments.

Video shows:

Machine's features

1. Non-contact 360° cleaning, not limited by space and location, no consumables.

2. No damage to the substrate. It has a better cleaning effect for substrates with high precision requirements, such as molds.

3. It can better control the heat input and prevent the substrate temperature from being too high or micro-melting.

4. The cleaning surface has high cleanliness and no pollution and can be used directly without secondary treatment.

5. The red light focusing is easy to operate, and the cleaning is repeated automatically.

6. The life of the laser source is 100,000+ hours, and it can work continuously for 24 hours.

7. Strong single-pulse light energy and high cleaning efficiency.

8. Wide range of material applicability, the cleaning laser is a flexible and efficient application to a variety of industrial processing scenarios.

9. Low requirements for the working environment, it is safe stable maintenance-free.

10. The laser cleaning head is extremely lightweight and can be operated by hand for a long time.

11. Patented red light-assisted focusing technology, can adjust the focus position according to different field lenses.

12. With real-time monitoring of optical path temperature, motor abnormality, laser abnormality, and automatic motor standby protection. The system is safer and more stable.

Parameter

Laser system | DS-C100 | DS-C200 |

Laser source | 1064nm Q-switch fiber laser | |

Nominal Laser Power | 100W | 200W |

Peak Power | >15KW | >30KW |

Cooling System | Air Cooled | Air Cooled |

Laser Class | Class 4 | Class 4 |

Energy per Pulse | 1.5mJ | 10mJ |

Preheat time | 0-10s | 0-10s |

Humidity | 10-95% | 10-95% |

Machine Weight | 60KG | 60KG |

Supply voltage | 210-230V | 210-230V |

Total Power Consumption | 480-490W | |

Fiber Cable Length | 5M/8M | 5M/8M |

Laser cleaner VS Traditional cleaning methods

| omparison | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry Ice Cleaning |

|---|---|---|---|---|

| Washing Method | Non-Contact Cleaning | Contact Cleaning | Abrasive Contact Cleaning | Non-Contact Cleaning |

| Harm To Base Material | None | Yes | Yes | None |

| Washing Efficiency | High | Low | Low | Mid |

| Consumable | Power | Chemical Detergent | Abrasive Paper, Grinder, Abrasive Stone | Dry Ice |

| Washing Result | Very Good, Very Clear | Medium, Uneven | Medium, Uneven | Good, Uneven |

| Precision Washing | Accuracy Controllable, High Precision | Uncontrollable, Low-Precision | Uncontrollable, Medium-Precision | -Uncontrollable, Poor Precision |

| Safety/Environment | No Pollution | Chemical Pollution | Dust Pollution | No Pollution |

| Operation | Easy to operate, portable, or automation optional | Complicated processes, higher technical requirements of the operator, and Pollution prevention measures are required | With more time & manpower, pollution prevention measures are required | Easy to operate, portable, or automatic |

| Investment | High investment in machines, but no consumable, low maintenance cost | Low investment in machines, but expensive consumables | Medium investment in the machine, high manpower cost | Medium investment in the machine, high consumable cost |

How can avoid laser damage the materials?

Material Sensitivity: Some materials are more sensitive to heat and energy than others. For example, certain plastics, composite materials, or heat-sensitive coatings may be more prone to damage from laser cleaning. Understanding the characteristics of the material being cleaned can help adjust laser parameters accordingly.

Laser Settings: The power, pulse duration, and other laser parameters must be optimized for the specific material and contaminants being cleaned. Using too much power or applying the laser for too long can result in excessive heating and potential damage to the surface.

Surface Characteristics: The condition and characteristics of the surface being cleaned can also affect the likelihood of damage. Rough or uneven surfaces may absorb laser energy differently, leading to localized heating and potential damage.

Surface Coatings: Laser cleaning can remove surface coatings such as paint or rust, but it’s important to consider the compatibility of these coatings with the laser process. Some coatings may be more difficult to remove or may require specific laser parameters to avoid damaging the underlying substrate.

Quality of Equipment and Operator Skill: The quality of the laser cleaning equipment and the skill level of the operator play important roles in preventing material damage. Proper training and experience enable safe and effective operation of equipment.

Samples

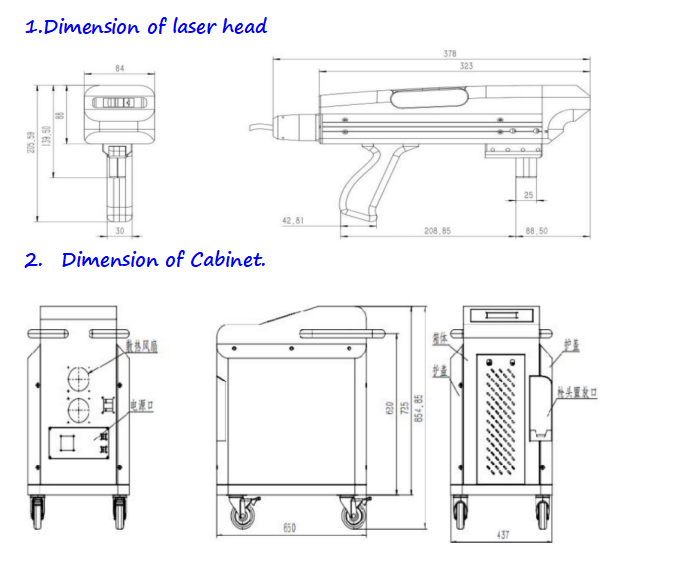

Machine's size

Certificate