100W Pulse laser cleaning machine

This pulse laser cleaning machine is design to remove organic and inorganic contaminants such as paints, rust, primers, cutting fluids, coatings, etc. Non-contact cleaning method; Minimal impact on base material; Low energy consumption and low noise level. Easy to operate and save process cost. Widely used for the surface laser degreasing, laser paint removal, laser removal of zinc, laser film removal, laser cleaning, such as coating, etc

Video shows:

Machine's feature

1. Non-contact cleaning without damaging the parts base.

2. Precision cleaning enables precise location and precise size selective cleaning.

3. No chemical cleaning solution required, no consumables, safe and environmentally friendly.

4. Easy to operate, just turn on the power, and can be handheld or used with a robot to achieve automatic cleaning.

5. The cleaning efficiency is very high and saves time.

6. The laser cleaning system is stable and requires almost no maintenance.

Parameter

Model

| DS-LC100

|

Laser power output

| 100W |

laser wavelength Cooling

| 1064±10 nm Air cooled

|

Pulse frequency

| 1~4000KHz |

Single pulse energy

| 1.5mj

|

Min.line width

| 0.1mm

|

Repeat accuracy

| ±0.001mm

|

Pulse width

| 8~500ns(adjustable)

|

Power supply

| AC220V±10%,50Hz

|

Working temp

| 0~40℃

|

Humidity range

| < 70% No condensation

|

Net.weight

| 45KG |

Applicable industries:

1. Mold and die.

2. Automotive Manufacturing.

3. Ship.

4. Food processing.

5. Sewage treatment.

6. Rubber tires.

7. Petrochemical.

Applicable materials:

1. Metal surface rust removal.

2. Metal surface paint removal treatment.

3. Cleaning oil, stains and dirt on metal surfaces.

4. Metal surface coating, coating removal.

5. Pretreatment of welding surface/spraying surface.

6. Remove dust and attachments from the surface of stone statues.

7. Mold residue cleaning.

How to choose pulse laser cleaning machine?

1. Consider the materials to be clean

Delicate or Sensitive Materials:

Pulsed lasers are ideal for delicate surfaces like historical artifacts, precision instruments, and electronics. For example, when cleaning a delicate 18th-century bronze statue, a pulsed laser can remove corrosion without harming the underlying metal. Data shows that pulsed lasers can reduce thermal damage by up to 50% compared to continuous lasers, making them the preferred choice for sensitive materials.

2. Evaluate the clean task complexity

High-Precision Requirements:

Pulsed lasers is suitable for delicate clean,its cleaning gun enables cleaning every complex angles. For instance, when removing rust from a car part, a pulsed laser can target the corroded areas without affecting the rest of the metal, achieving a 95% reduction in rust with minimal surface damage.

3.Consider the speed and efficiency

Fast Cleaning:

Pulse lasers generally offer faster cleaning speeds, making them ideal for industrial applications where time is of the essence. Data indicates that pulse lasers can clean large areas, which is crucial in high-throughput environments like automotive manufacturing.

4. Budget of machine

Cost Efficiency:

Continuous lasers tend to be more cost-effective for large-scale industrial applications due to their speed and simplicity. However, they may require higher energy consumption, which can increase operational costs over time.

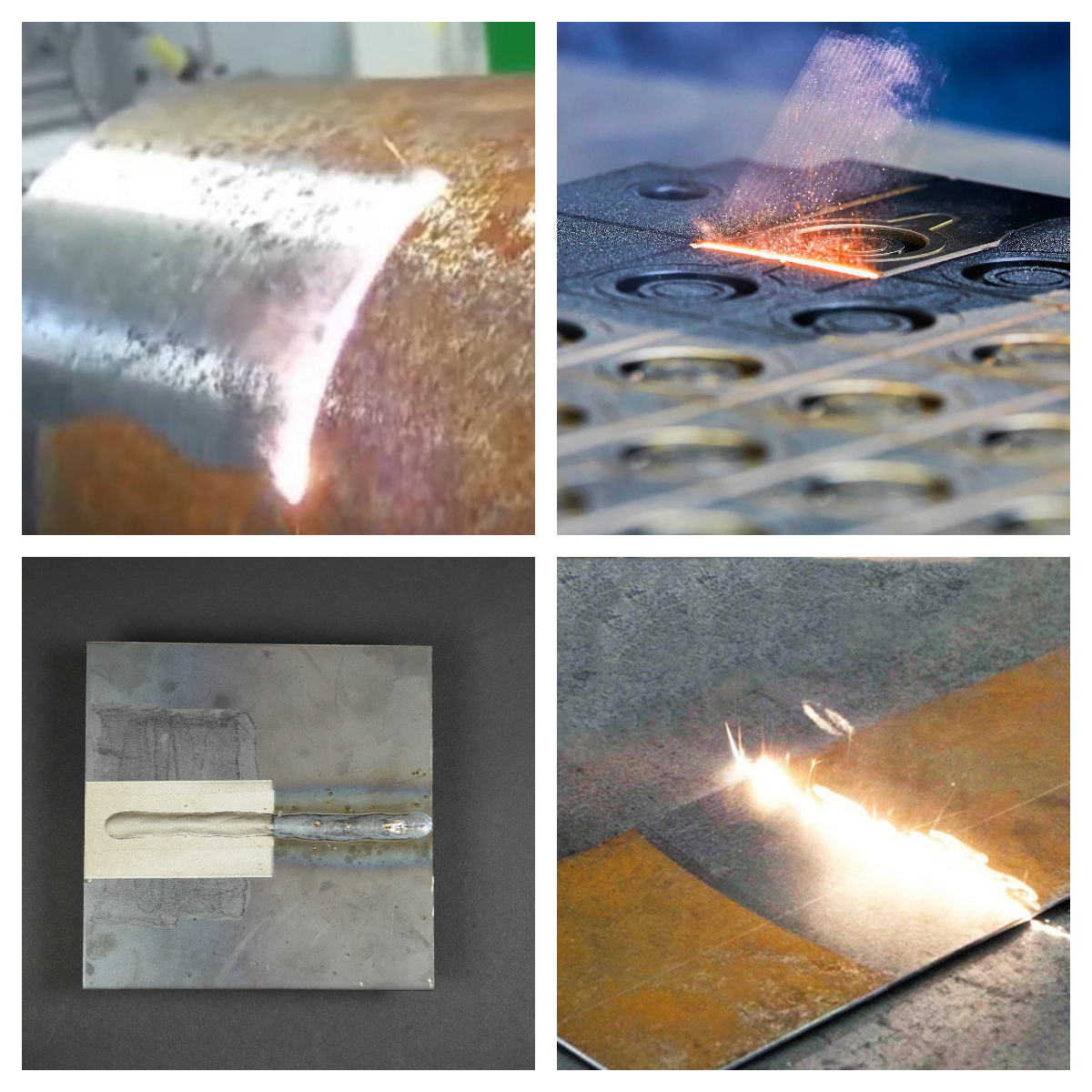

Samples

Certificate

FAQ

Q1: How does the package?

A: Dotslaser provides 3 layers package. For the outside, we adopt wood craft case. In the middle.the machine is covered by foam, to protect the machine from shaking. For the inside laser machine, the machine is covered by thickening plastic bag for waterproof.

Q2: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and ourshipping agent have full experienced in safe transportation. We have exported to 100 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q3: How to install and run the machine?

A:Our worker will install all the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine 95% customers can learn by themselves.

Q4: How can i do if the machine goes wrong?

A: lf confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we

can to solve it for you.