Laser cleaning on cultural relic

Laser cleaning machine is a highly advanced technological innovation that has revolutionized the cleaning industry. It is a powerful tool that uses beams of highly concentrated light to remove dirt, dust, rust, and other contaminants from various surfaces. The machine is easy to operate, efficient, and environmentally friendly, making it a popular choice among professionals across various industries. The laser cleaning machine is effective at removing unwanted contaminants from a wide range of surfaces, including metals, plastics, stones, and other materials. The beams of light are highly focused and can be adjusted according to the specific cleaning requirements. Thisis very suitable for cleaning delicate surfaces, such as historical artifacts, sculptures, and other priceless artifacts.

Video shows:

Machine's advantages:

1. Non-contact cleaning

Laser cleaning without damaging the parts base, proper laser power enables perfect cleaning on the cultural relic no damage to the surface of the cultural relic.

2. Precision

Laser cleaning enables precise location and precise size selective cleaning, enery tiny corners can be cleaned easiy by using laser cleaning technology.

3. Less consumables,less cost

No chemical cleaning solution required, no consumables, safe and environmentally friendly.

4. Automatic cleaning

Easy to operate, just turn on the power, and can be handheld or used with a robot to achieve automatic cleaning.

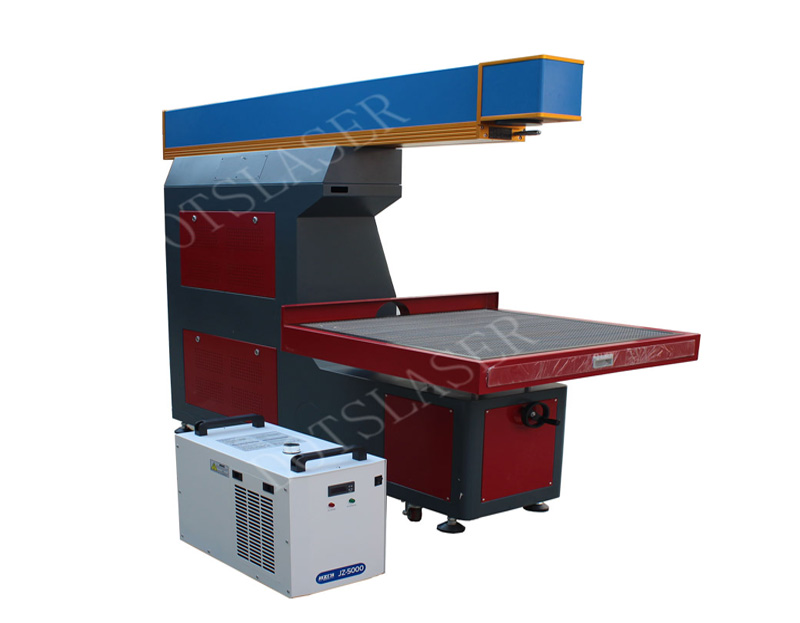

Parameter

Product | Laser cleaning machine |

Laser wavelength | 1080±1nm |

Laser source power | 1000W/1500W/2000W/3000W |

Voltage | 220V/380V, 50/60 HZ (Transformer available) |

Scan width | 0-300mm |

Environment humidity | ≤70% without condensation |

Laser type | Continuous/modulation |

Cooling method | Water cooling |

Total power | 6000-10000W (including chiller) |

Cooling water requirements | Purified or distilled water |

Cleaning efficiency | 15-45m²/h |

Machine dimension | 870x560s1050mm |

Cable length | 7m |

Machine weight | 145/165/180kg |

Laser cleaning on cultural relic applications:

Laser cleaning is to locate the laser beam to the surface of the metal cultural relic, and remove the pollutants through the radiation effect of the laser to achieve the cleaning effect Laser cleaning technology has the characteristics of non-abrasive, non-contact, high efficiency and suitable for various materials, and its application in the field of cultural relic protection has attracted increasing attention. To improve the application of laser cleaning technology on metal cultural relics, lots of works have been carried out.

1.Bronze relic cleaning

2. Painting cleaning

3. Ceramic products

4. Ivory products

5. Wood crafts

6.Textile crafts

Why use laser cleaning techniques on cultural relic?

Cleaning is the first step in the treatment and protection of metal relics, which usually refers to the removal of contaminants (e.g. dust, old coatings or burial deposits) and corrosion layers. Traditional cleaning methods include mechanical method, sandblasting method, ultrasonic method and chemical method.

▼Mechanical method refers to the use of physical friction contact principle to remove the attachment and loose rust on the surface of cultural relics with tools. This cleaning method consumes time and energy, and has low efficiency.

▼Sandblasting method applies the injection of metallic or ceramic powder to clean the surface of metal cultural relic, operated in a special sand storehouse, and after sandblasting material surface roughness is larger.

▼Ultrasonic method uses the micro-mechanical shock wave generated by ultrasonic wave to shake off the dirt attached to the surface of metal cultural relics, so as to achieve better cleaning effect and improve the efficiency of rust removal . However, due to the limitation of the interior space of the ultrasonic equipment, this method is only suitable for small metal relics.

Chemical method uses chemical reagents to react with the rust layer on the surface of metal cultural relics to achieve the purpose of rust removal. However, some chemical reagents have certain toxicity and corrosion, which may damage the surface of metal cultural relics and pollute the environment . It can be seen that the traditional cleaning methods cannot be effectively guaranteed in terms of cleaning quality, cleaning efficiency and environmental protection because of technical limitations. A new cleaning technology is urgently needed to solve this series of problems. The emergence of laser cleaning technology gives hope to cultural relics conservators.

Shipment and package

Certificate