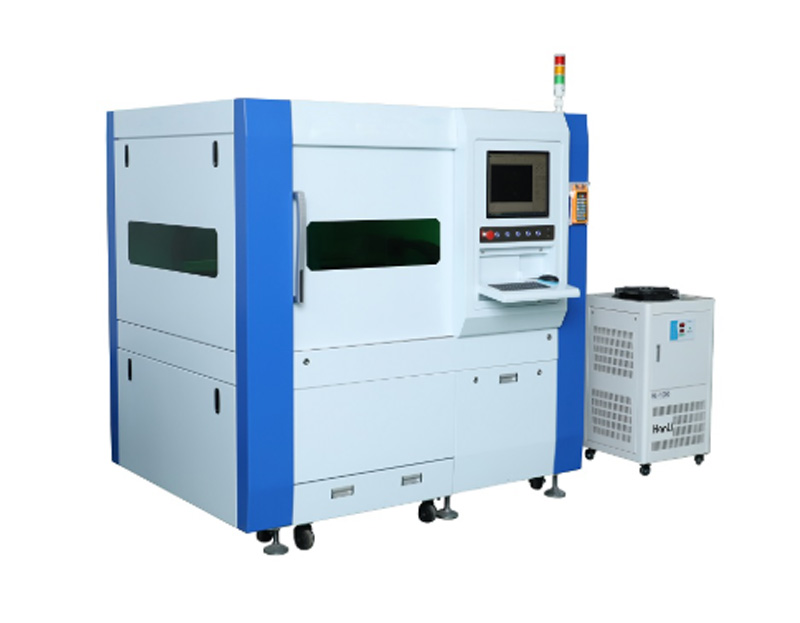

Small handheld laser cleaning machine

The laser cleaning machine is a powerful tool to remove rust and oil impurities using laser technology, it uses a powerful laser beam pointed at the surface of the cleaning material, the laser beam rapidly heats and evaporates the unwanted material, which is then removed by a suction system. The laser cleaner is use non-contact process, it won't cause waste consumables or do damage to the materials, and it's friendly to environment, it is also an exact process that can remove the smallest particles or residues without damaging the surface or leaving any residue.

Video shows:

Features

1. Top brand CW laser source,welding gun&controller,water chiller.

2. Fast,360 degree uniform results.

3. Applicable to a wide variety of industrial applications.

4. User friendly handheld strain free operation.

5. Cabinet with easy roll casters.

6. Simple and friendly operation interface.

7. No consumables required except lens.

Parameter

Laser power | 1KW/1.5KW/2KW/3KW |

Scanning width | 0-300mm |

Laser type | continuous |

Power consumption: | 5.5~9.5KW(chiller included) |

Cleaning efficiency: | 15~45㎡/h |

Cable length | 7m |

Laser wavelength | 1064±5nm |

Voltage | 220V/380V,50/60Hz |

Environment humidity | ≤70%,no condensation |

Cooling method | water cooling |

Cooling water requirements | purified or distilled water |

Applications:

Surface cleaning: Laser cleaning can remove contaminants like rust, oil, and paint from a variety of materials, including metals, ceramics, and automotive parts.

Mold cleaning: Laser cleaning can remove release agents and residuals from molds used to make rubber, plastic, glass, and composite products.

Weld cleaning: Laser cleaning can be used to clean welds on steel, stainless steel, and aluminum without damaging the substrate.

Marking: Laser cleaning can be used for marking or labeling.

Sterilization: Laser cleaning can be used to sterilize critical equipment in medical and food applications.

Art restoration: Laser cleaning can be used for art restoration

Product's main components

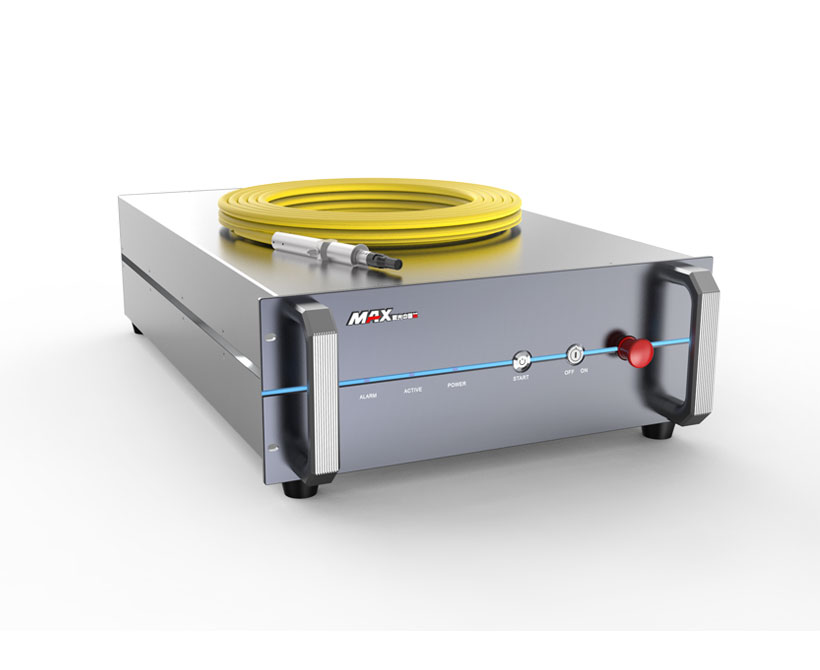

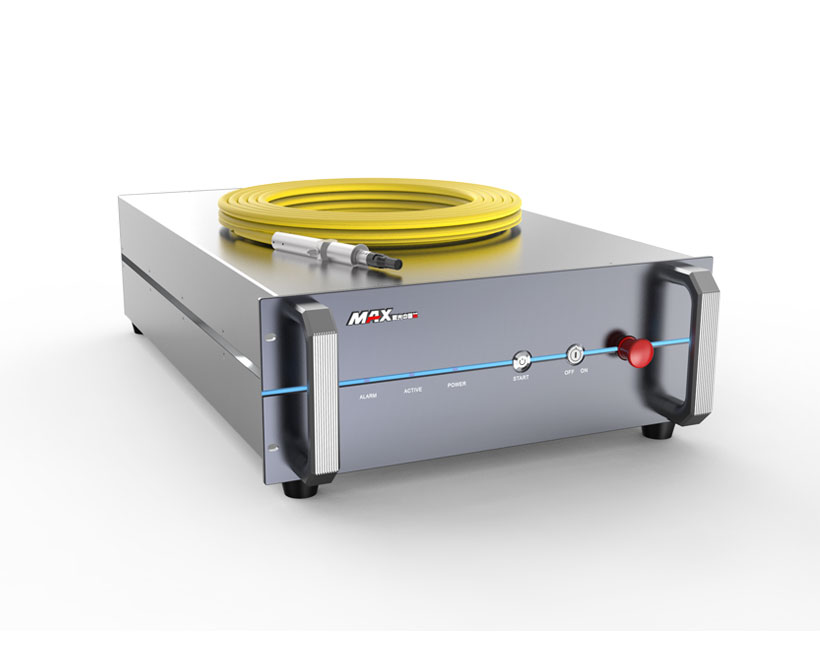

1. Laser source

Stable, high efficiency, energy saving,bascially maintenance free, good experience, low cost.

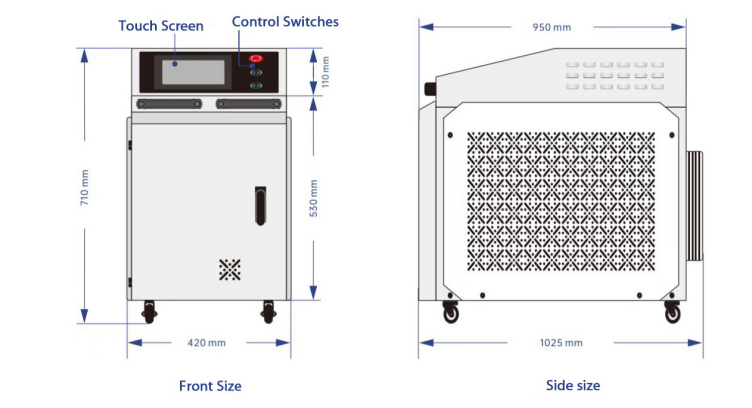

2. Chiller

Intelligent control, self-adaptive hot and cold dual temperature adjustment ,separate cooling of cleaning head and laser source, stable laser output, fast and energy saving.

3. Smart control panel

Full touch screen operation interface, multilingual support work status is clear at a glance, process library design, set once, use at any time.

4.Neat wiring

The selection of components has been scientifically calculated, the layout is reasonable, the logo is clear and easy to maintain.

What are the advantages of laser head?

1. Light weight,only 0.7kg, easy to use

2. 400mm focal length, cleaning width can be up to 150±10mm

3. Shorter focus, large cleaaning width, low laser attenuation

4. Flexible and easy to use on large irregular workpieces

Attention of using laser head

1) Ensure reliable grounding before power supply.

2) The laser output head is connected with the welding head. Please check the laser output head carefully when using it to prevent dust or other pollution. When cleaning the laser output head, please use special lens paper.

3) If the equipment is not used in accordance with the methods specified in this manual, it may be in abnormal working condition and cause damage.

4) When replacing the protective lens, please make sure to protect it.

5) Please note: When using for the first time, when the red light cannot come out of the copper mouth, be sure not to emit light

Machine's size

Samples

Certificate