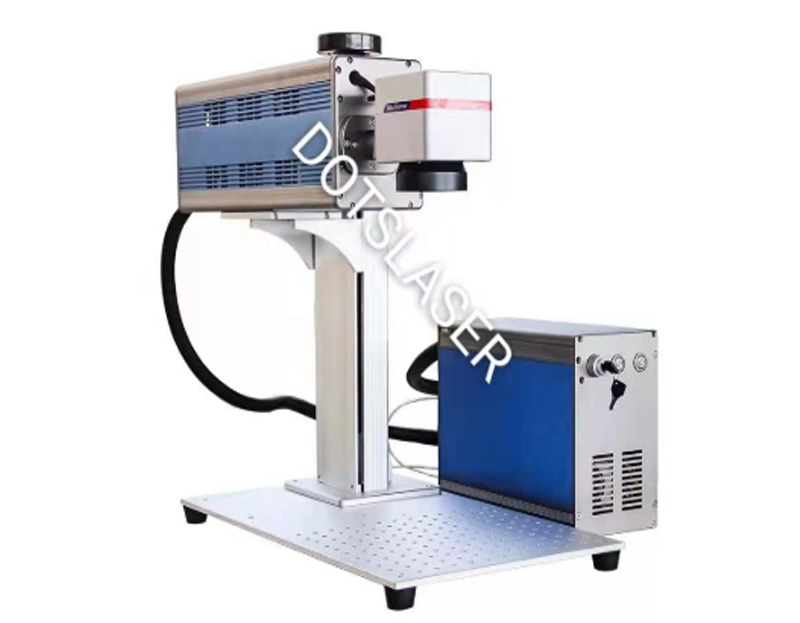

Big galvo fiber laser engraver

The emergence of laser marking machines has revolutionized modern technology. With fiber laser machines gaining immense popularity among customers, it's not hard to see why. Thanks to their impressive advantages and versatility, these machines can mark a wide range of materials, including metal sheets, aluminum, copper, steel, stainless steel, and even titanium. Boasting high-speed precision and exceptional marking capabilities, it's no surprise that many manufacturers prefer fiber laser marking machines.

Fiber laser engraving video displays:

Fiber laser engraver features:

1. Energy conversation

No consumables and free maintenance, our machines consume only about 0.35 kilowatts of electricity per hour, which is both energy efficient and environmentally friendly.

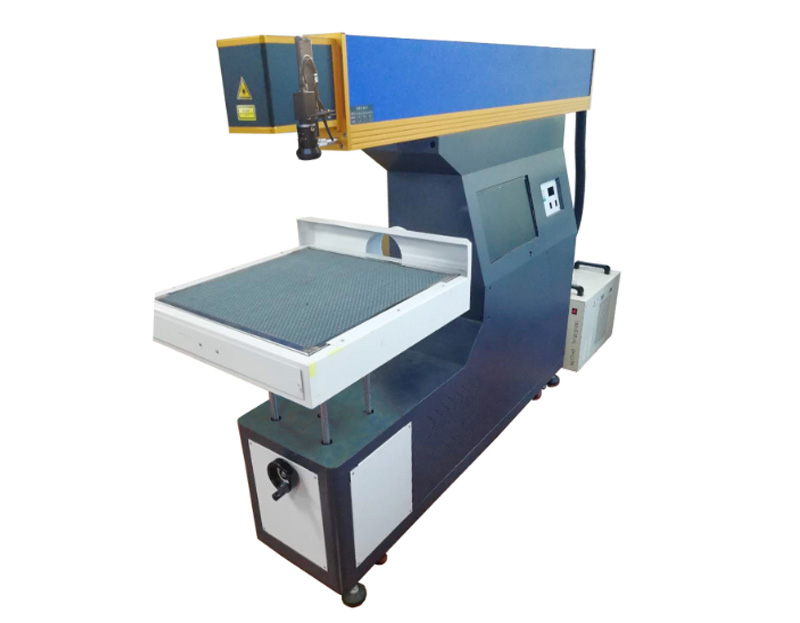

2. Large marking area

Boasting a spacious working area of up to 600 mm x 600 mm, the fiber laser marking machine shatters conventional size and format constraints. Equipped with an impressive XY axis size of 800 mm x 3 mm, it effortlessly tackles sizable and intricate objects.

3. Reasonable design

Full Protection from fiber laser through the large observation window, visible red laser for alignment and preview

Parameter

Power | 100w |

Marking area | 600x600mm |

Marking line width | 0.01mm-0.1mm |

Min. Character size | 0.15mm |

Power adjustable range(%) | 0-100(adjustable) |

Marking speed | 0-7000mm/s |

Optical cable | 3m |

Las r wave length | 1064nm |

Cooling way | Water/air |

Voltage | 110v/220v, 50/60hz |

Repeat frequency | 20-80khz |

Repeat accuracy | ≤0.01mm |

Support format | PLT,DXF.AI,JPG,BMP,PNG. |

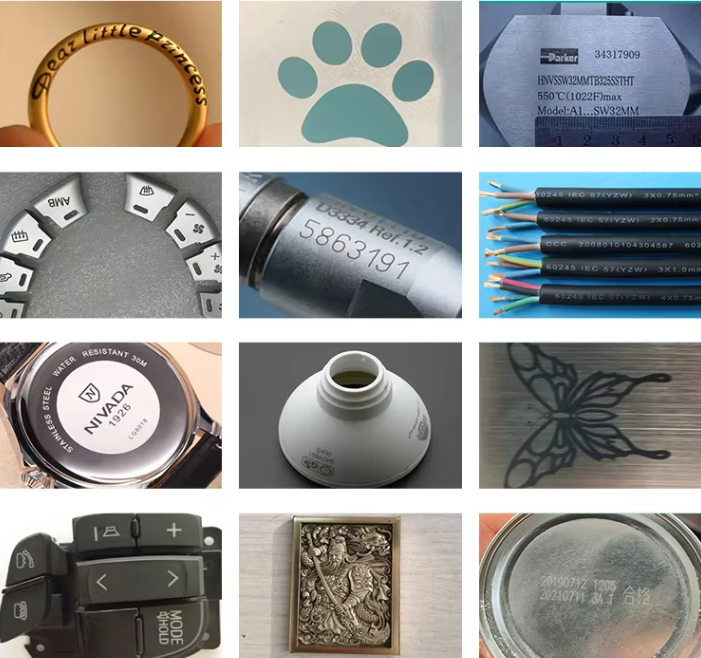

Fiber laser marker application:

The laser marking machine has wide applications and is primarily employed for marking logo, words, brand, date, series number, batch number, sign, drawing, photo, QR code, etc. on the surface of metal & non-metal material. The range of metals include stainless steel, alloy, metal plate, aluminum, silver, gold, etc. and the non-metals include plastic: engineering plastic and hard plastic, etc. It is also used in electronic equipment, such as- integrated circuits, mobile communications, precision instruments, glass watches and clocks, computer keyboards.

Daily maintenance of lens:

The field lens will be polluted by the dust when we process, and the reflectivity will be reduced, which is not conducive to the laser processing in the future. Therefore, we must ensure the cleanliness of the mirror, check the mirror regularly, if polluted, we can use anhydrous ethanol to clean the lens, and then wipe the mirror with absorptive cotton; The lens in the focusing mirror must pay attention to protection, because the pollution will affect the output of the laser, if accidentally polluted, you can first remove the blow pipe and protective sleeve, remove the lens and then blow the floating dust on the surface of the focusing lens with a balloon, and then wipe the lens surface with a absorbent cotton dipped in anhydrous ethanol.

Product detail presentation:

1. Product size

Compact design enables moving easily, no space limited.

2. Light path

High quality light path,red light laser beam accurately points out the object's position.

3.Computer screen

Reliable software, support multiple languages,easy to operate.

4. High speed scanner

Most of manufacturers use digital galvo scanner.

Fiber laser samples display:

Machine's shipment and package