Fiber laser flying marking on beverages

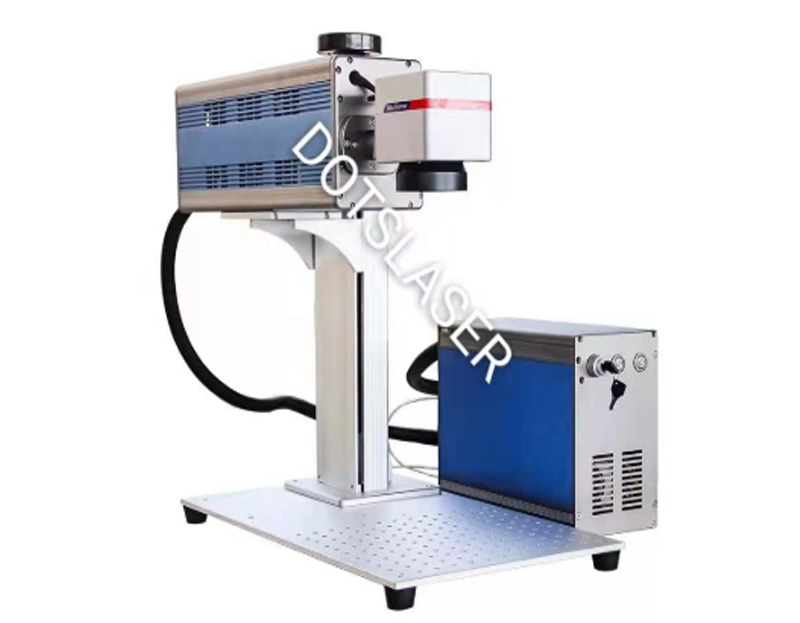

Fiber laser flying machine is a high-speed continuous marking machine designed to improve productivity. It adopts MAX industrial-grade high-performance laser source(optional) which are with stable performance, fast processing efficiency and marking speed on the production line. It can reach high speed up to 200 meters per minute with high-yield application identification requirements, it mainly used in production date, anti-counterfeiting, medical and food/beverages packaging industries.

Video shows:

Machine's features

1. Permanent marking

Fiber laser flying machine with high speed galvanometer system, reliable laser source, output stable laser beam with good marking result, its engraving effect won't fade with time goes by, ensure product's engraving quality, increase productivity.

2. Less maintenance cost

Dotslaser machine has 1 year warranty, during 1 year if inner machine has problems we can fix it with free. Dotslaser machine alway adopts high level accessories, power laser source, it won't has problems in fact, it helps reduce maintenance cost.

3. Fast engraving speed

Fiber laser flying machine is equipped with high speed scanner, quick reaction sensor, it can aim the products quickly and mark on it, continuous laser marking, no need manual operation, saves labor cost and processing items time.

4. Easy to operate

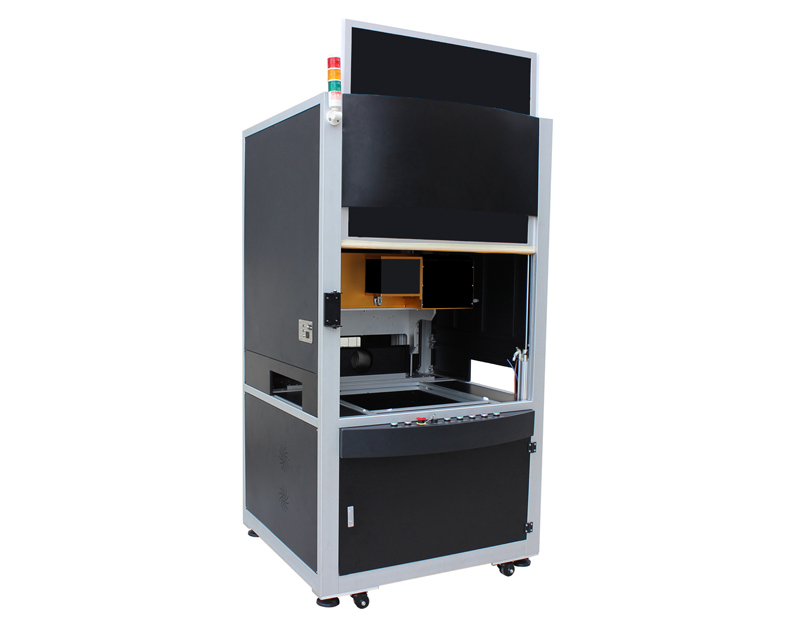

This mahine is equipped with simple software interface, marking software supports various file formats and languages, easy to operate,even you are a new hand you can master it quickly, design compact size with four roller casters,easy to move,convenient to use.

Parameter

Model serials

| T serials(Max laser source) | |

Model | T200 | |

Laser parameter | Laser source model | MFP-20G/20X |

Output power | 18.5W | |

Beam quality M2 | ≤1.4 | |

Pulse repetition frequency | 27-60 KHZ | |

Laser wavelength | 1064±5 | |

Output power stability | <3% | |

Working life | About 100000 working hours(non lifetime) | |

Optical properties | Marking range | 100-300mm |

Engraving depth | ≤1 mm (depending on power and time)

| |

Engraving speed | ≤10000mm/s

| |

Repeat accuracy | ±0.002

| |

Minimum marking line width | 0.1mm

| |

Minimum character height | 0.15mm

| |

Use environment | Cooling way | Air cooling |

System power supply | 500W/220V/50Hz(110Vcanbeconnected)

| |

Temperature humidity | 0~40°,30%RH85%,airconditionershouldbeinstalledwhenusedoutsidetherange

| |

Oil mist condensation | Not allowed

| |

Other parameter | Operating system | Fly control system |

File format

| The software supports text, Model serials T serial(MAX laser source ) QR code, bar code, serial number, graphics and other marking content

| |

Dimensions

| 660X510X1460 mm

| |

Packing size | Host: 790X740X350mm Column: 1350X350X280mm

| |

Total weight | About 66KG | |

How Does Fly Laser Marking Work?

Fly Laser Marking is a dynamic process. It marks an object while it’s in motion. Thus, this method is also called automatic laser marking or conveyor laser marking. Whether you want to start a beverage business, a fly laser marking machine can greatly help you. You must include some information about your beverage bottle. The most critical info is the production & expiry date, batch number, and import information. A fly laser printer can create permanent marks on glass, plastic, or aluminum. You can use these benefits to mark the mentioned information on beverage bottles.

Step 1: Prepare your machine

First, you should check your machine, make sure the convery belt is running smoothly, when you places the bottles, there is no risk of falling of misalignment.

Step2: Loading the design and date

Before you start engraving, make sure every cables is properly installed in the machine, after that, you can load your design and data to the software, adjust correct parameter makes best engraving result.

Step 3: Adjusting the laser parameter and focusing

Onced the design and data are ready, please double check the laser parameter settings, adjusting the focusing or use auto focusing at first, and next start engraving, when finish engraving, remember cleaning the workbench and model,in case have dust on products.

Why use fiber laser mark on beverage?

1. Quicker,easier and more accurate

Laser marking on beverages is permanent, it has wide range applications. It can mark on various materials including plastics and metals, minimal waste – no pre-treatment or post-treatment is required. Furthermore, it provides incredibly precise results with detailed text, characters, barcodes as well as time & date stamps. In addition to this, laser marking machines have a long service life meaning they require little maintenance – everything necessary to keep production running smoothly!

2. Resistant to Corrosion or Wear

Long lasting marking ensures product longevity which can enhance the ability of a company to produce trustworthy products, laser marking on beverages is a great choice for any business looking to maximise their brand exposure in a cost-effective manner.

3. Beverages traceability makes more reliable

In the beverage industry, laser marking is proving to be an invaluable asset for product traceability. This technology enables the permanent application of high-contrast markings onto a wide range of materials, quickly and conveniently. Laser markings are absolutely clear, meticulously accurate and show unparalleled durability, making them a perfect choice for food labelling.

4. Cost reduction benefits

Laser marking is a best choice for labelling in the beverage industries due to its cost reduction benefits. This type of technology enables manufacturers to construct more clearly visible, accurate and permanent labels on their products. There is no need for businesses to buy additional supplies such as printed labels, inks and consumable parts which cuts costs significantly. Laser marking requires very little maintenance work ensuring that overheads associated with the production line remain low.

Samples

Certificate