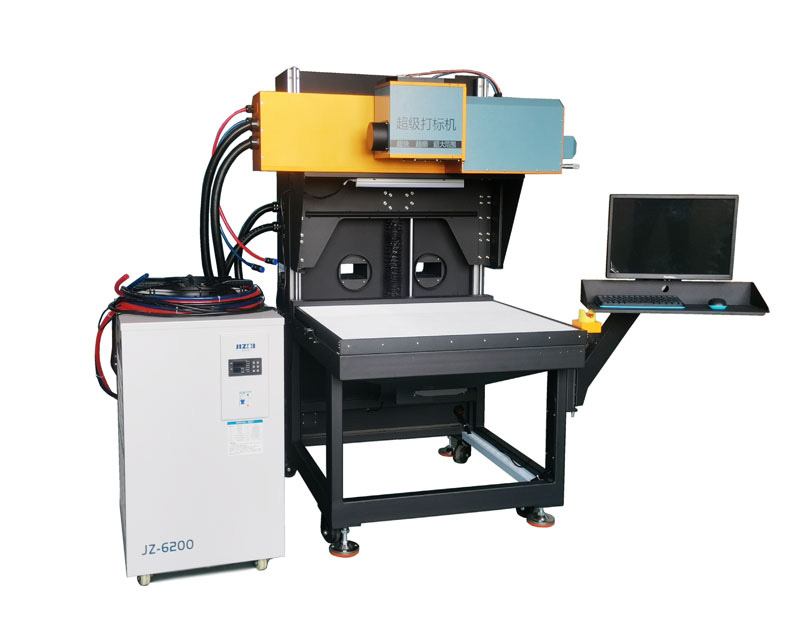

Fiber laser marking for sanitary ware

With the continuous improvement of national living standards, people has higher requirements for the functionality, aesthetics, durability and other aspects of kitchenware. In order to better adapt to the life concept of customers, many kitchenware manufacturing enterprises continue to explore new production processes and upgrade processing equipment. Laser marking machine as a new era of processing tools, has become an ideal choice for different kitchen brands.

Why we need use laser to customized kitchen ware?

Kitchens are complex wonderlands. These are places where the best concoctions and recipes were made and discovered. But before all of that sumptuous food gets in your stomach, processes come along with cooking—which requires the best kitchen utensils.

Cooking is a creative form of labor, whether you’re preparing a rigorous recipe or a quick snack. From sourcing fresh ingredients to choosing suitable kitchen utensils, you need to put your mind and heart to cook it well. You might think that a silicone utensil set with a wooden handle is no different than its metal counterpart, but they affect your dish in various ways.

Video shows:

Machine's features:

1. Durable

Laser-marked kitchenware products, with high wear resistance and fade resistance; Laser welding kitchen utensils, high welding quality, beautiful weld and high hardness, can effectively ensure the durability of kitchen utensils.

2. Multiple functions

Laser marking machine variety, can provide kitchen manufacturers with marking, engraving, welding, cleaning, cutting and other processing equipment, powerful

3. Wide applications

Kitchenware products manufacturing materials, involving wood, glass, ceramics, metal, silicone, plastic, etc., laser marking machine can be compatible with most of the metal and non-metal materials on the market, to achieve different processing technology.

4. Environmental protection

Laser marking is a non-contact process, in the entire process, the kitchen will not produce mechanical stress, without the use of any ink or chemicals, safe and environmentally friendly.

5. Automate

According to customer needs, software development and function expansion can be carried out, the laser equipment can be integrated into the existing production line, and integrated automatic control can be carried out to improve production efficiency.

Laser marking machine, as a popular kitchen products marking process, can provide exquisite and permanent marking effects for spoons, utensils, pot and tableware in the kitchen. For example, add brand name and product model on the wok to enhance brand recognition; Create a colorful design on the stainless steel spoon to bring a beautiful eating experience; Wooden plates are marked with complex patterns and words to provide customers with personalized customized services.

Parameter

NO. | Model | DS-LM20 |

1 | Laser source | Fiber generator |

2 | Engraving depth | ≤0.2mm(depends on material) |

3 | laser wavelength | 1064±10 nm |

4 | Marking area(2D) | 100×100mm/150×150mm/200×200mm |

5 | Pulse frequency | 20~80KHZ/1~600KHZ/1~4000 |

6 | Max marking speed | 8,000mm/s |

7 | Repeat accuracy | ±0.001mm |

8 | Min.line width | 0.01mm |

9 | Min.character size | 0.2mm |

10 | Cooling | Air cooled |

11 | Working temp | 10~35 ℃ |

12 | Humidity range | < 70% No condensation |

13 | Power supply | AC220V±10%,50Hz or AC110V±10%,60Hz |

14 | beam quality | m2<1.5 |

What's the benefits of“Laser Logo Engraving on cookware”?

▼Personalization

Uniqueness and Individuality: Laser-engraved logos allow individuals to personalize their cutlery sets with names, initials, or custom designs..

Meaningful Gifts: Personalized cutlery sets make memorable and thoughtful gifts for special occasions like weddings, anniversaries, or housewarmings.

▼Branding for Businesses

1. Reinforcing Brand Identity: Restaurants, hotels, and catering businesses can engrave their logos onto cutlery sets, reinforcing brand recognition and identity.

2. Professional Image: Customized cutlery sets with the company logo create a professional and cohesive image, leaving a lasting impression on customers.

▼Durability and Longevity

Permanent Engravings: Laser-engraved logos are permanent and resistant to fading or wearing off, ensuring the design remains intact even after regular use and washing.

Scratch Resistance: Unlike traditional methods like printing or stickers, laser logos are scratch-resistant, maintaining their aesthetic appeal over time.

▼Hygiene and Safety

1. Smooth Engraved Surfaces: Laser-engraved logos do not affect the hygiene or safety of the cutlery set. The engraved surface is smooth, preventing bacteria buildup and making cleaning effortless.

2. Non-Toxic and Food-Safe: Laser engraving is a safe and non-toxic process, ensuring that the cutlery remains food-safe and suitable for everyday use.

What's the practical considerations for Laser Logo Engraving on Cutlery Sets?

A. Material Selection

Stainless Steel: Stainless steel cutlery sets are the most common choice for laser engraving due to their durability, corrosion resistance, and smooth surface.

2. Other Materials: Laser engraving can also be applied to materials like titanium, silver, or gold-plated cutlery, depending on the specific requirements.

B. Design Complexity and Size

Design Complexity: The level of intricacy in the design affects the engraving time and cost. Highly intricate designs may require additional time and precise calibration.

2. Size Considerations: The size of the cutlery piece determines the available space for the logo, influencing the design choices.

C. Customization Options

Font Styles and Graphics: Laser engraving allows for various font styles and graphic elements to create personalized and visually appealing logos.

2. Multiple Piece Sets: Cutlery sets often consist of multiple pieces, providing opportunities for consistent branding or customized designs on each piece.

Samples

Reliable utensils are user-friendly

Silicone utensils work best with non-stick pans making them user-friendly for casual cooking. Since they are made of rubber, they won't scratch on your metal wares.

At the same time, they are toxin-free (given the right temperature) and are more durable than cooking wares made of plastic.

Another upside is: you won't have a hard time cleaning them. Sleek and comfortable to use, they are the best kitchen utensils that do the job even with low maintenance aftercare.

Customized this kinds of kitchen ware with unique style make your life more colorful.

Shipment and package

After-sales service

1. Quality assurance and after-sales service

The warranty period of the equipment shall be 12 months since the equipment be used by the customers, the installation and debugging is completed and the equipment is accepted by the demander. Dotslaser attaches great importance to the after-sales service work of the product, once the product is delivered to the user, the company immediately established the user after-sales service file, and regularly track the user's product use status, solve and answer all the problems of the user, received the user's notification information about the equipment failure, the company's workers can make a rapid response within 2 hours. If the telephone guidance is difficult to troubleshoot, our company's technical staff can arrive at the customer site within 24 hours to provide support.

2. Installation and debugging

Before machine installation, our factory will offer you a basic structure installation file,the good need 2 weeks delivery to you there , the engineers of Dotslaser will arrive at your site and inspect the machine again. Comfirm all the conditions meet the installation and commissioning requirements of the equipment, the equipment will transport in time. The installation and commissioning time of the equipment is about five working days, the first three days are connected to the use of the system, and the system is operational after the service project. The engineer will train qualified operators on basic maintenance procedures and general operating characteristics of the equipment in the next two days

3. Service support

If there has any problem with any part of the system during the warranty period, Dotslaser well-trained service engineers are ready to provide cellphone call or begin on-site service,if the machine has any problem during the warranty period,please contact us directly !