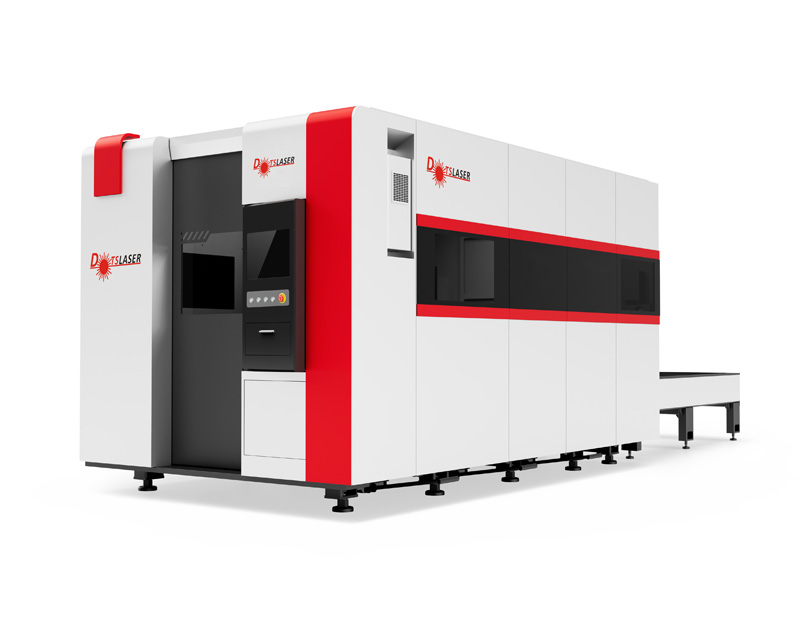

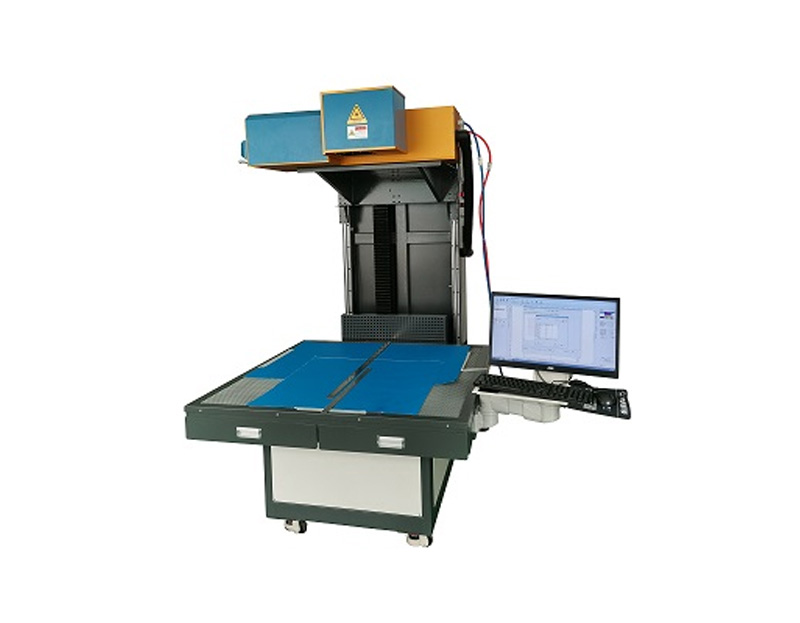

Large area fiber laser marking machine

Large area CNC laser marking machine adopts top-level laser source, high quality and thick metal sheet, smart sensor and control board, high precision and fast marking speed are the most obvious advantages in this machine, large workbench is suitable for mass production, increase productivity greatly, it's a useful tool for many manufacturers, marking effect also warm welcomed by many customers.

Video shows:

Machine's feature

1.Stable performance

Large worktable with high stable performance, even marking tiny characters didn't cause deformation.

2.Excenllent uniformity

Flat worktable ensures laser beams optput all the same, avoid happening the situation like somewhere with deep color marking, somewhere with light color marking.

3. High quality laser source

Top-level laser source guarantees perfect marking effect, deep marking effect attracts many customers.

4. High precision

Dotslaser adopts high speed scanning galvanometer system, highest speed can reach up to 8000mm/s, delicate marking line.

Parameter

Name | Large area fiber laser marking machine |

Laser type | Fiber laser |

Cooling mode | Air cooling |

Marking area | 1000x1000mm, 1300x1300mm,1300x2500mm, 2500x6000mm. |

| Mode of operation | Continuous wave |

| Applicable material | Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wood |

Core component | Laser source |

Feature | Deep marking |

Working temp

| 0~40℃

|

Applicable industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other |

Warranty | 1 year |

| System language | CN/EN/ES/PT Other Support Customization |

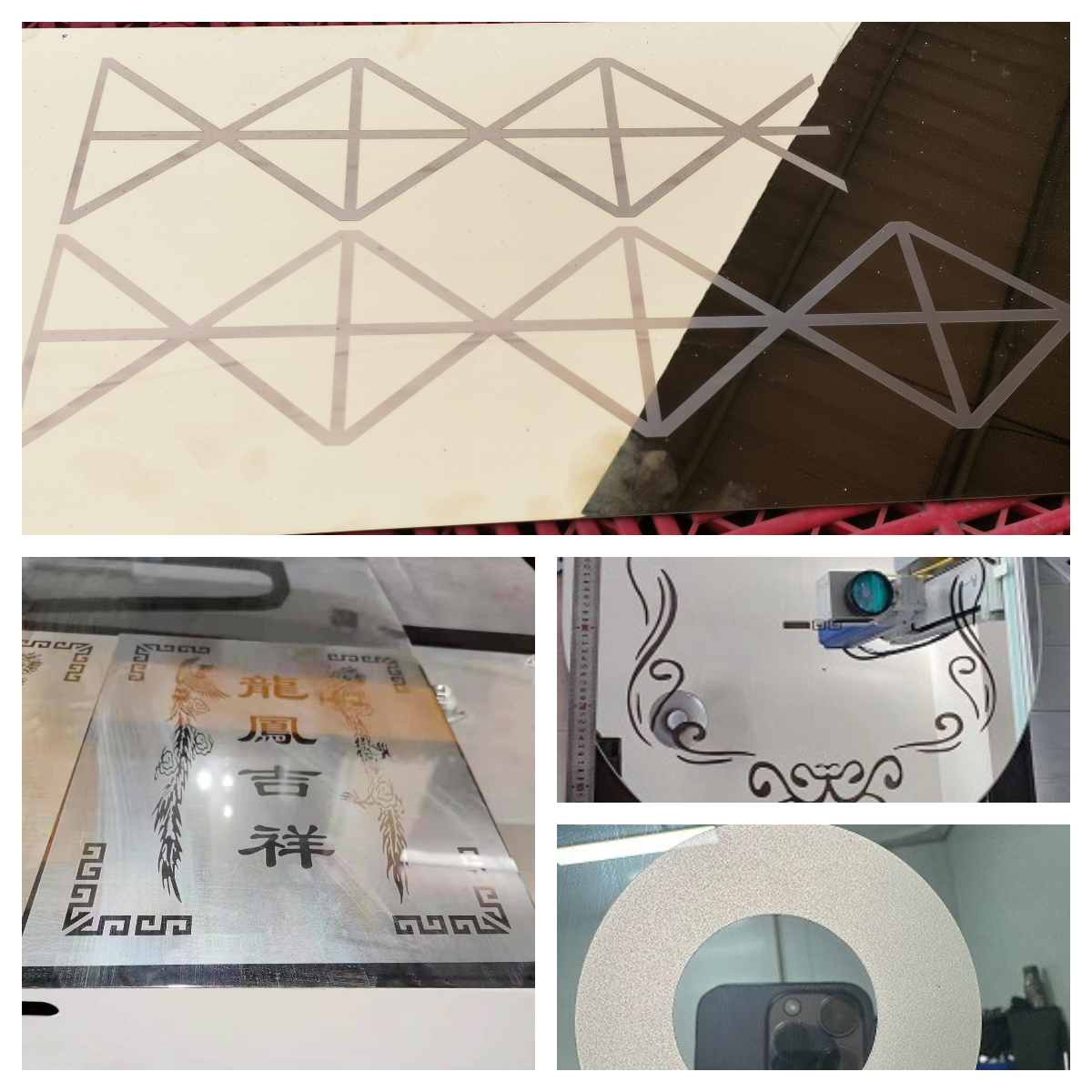

Applications:

Large laser marking machine mainly use for engraving on metal,such as stainless steel, carbon steel,steel, and also marking on the mirror, sandblasting technbiques are welcomed in the market. It is widely use in some industries like salon , building industries, in-home decoration, laser-engraved LED mirror decoration can be used in decorating bathrooms, vanities, living rooms, dressing rooms, bedrooms, dining rooms, hallways, and more. LED mirrors with laser engraving could further produce a richer and more realistic reflection of the effects in makeup and beauty salons, creating a perfect brightness that makes makeup, shaving, grooming, etc., much more accurate and effective.

Daily maintenance of your large fiber laser marking machine:

1. Regular Cleaning:

Usually cleaning the work area, lens and mirrors in case dust and debris to influence the good performance, using soft cloth to wipe down the surfaces, making sure that the optics are free from contaminants.

2. Check and Clean the Cooling System

The cooling system prevents overheating. Check the water tank, coolant levels, and cooling lines from time to time for proper functioning. Replace the coolant periodically and clean the cooling system to avoid blockages.

3 Inspect and lubricate all the moving parts

Keep the rails and motors properly lubricated. Lubrication cuts down on friction and wear, which provides smoother movement and greater accuracy with engraving. Take a look at the rails from time to time for any damage or misalignment.

4. Laser Calibration

The laser should be regularly calibrated to maintain its precision. Misalignment can lead to poor engraving results and cause unnecessary wear on the components. Regular calibration ensures that the engraver is performing optimally.

5. Inspect and Replace Consumables

Consumables include lenses, nozzles, and filters. Check for wear and tear and replace them to ensure quality cuts and engraving. The lens should be free of any residue that can distort the laser beam.

6. Keep the Software and Firmware Updated

Update the software and firmware of the engraver regularly, thus making it compatible with any newer designs and improvements in performance. Updates generally come with fixes to bugs, new features, and enhancement to laser control.

7. Look for Electrical Issues

Run periodic checks on electrical connections, the power supply, and total electrical integrity of the system. Faulty connections or power surges may seriously damage the engraver and make operation unexpected.

Samples

Shipment and packing

Certificate