Laser Engraving Computer Accessories

Computer has been use for working or studying usually,it's essential in life,design a unique computer patterns is very common when you choose to buy a digital products.Nowadays, everyone pays more attention to the upgrade of accessories,this fiber laser machine can meet your design requirement.

Video shows:

What Is Laser Engraving?

Laser engraving technology uses a strong, focused laser beam to engrave what you want on the materials,and it's non-contact,your material without damage anytime. However, this process engraves really complex types of designs, patterns, images, and text into the surface of the material. This ability makes it quite popular among retailers and sellers.

What's the advantages of laser engraving machine?

●Precision

The most obvious advantages of laser engraving machine is its precision,laser machine can engrave materials fast and accurate,because this machine is equipped with high technique computer numerrical control. They have the ability to engrave or etch highly complex and delicate patterns on a vast range of materials like glass, wood, metals, etc.

● Versatility

Laser engraving machines another obvious advantage is its versatility. These machines can handle a variety of materials and serve diverse purposes.It has wide applications and can fit for engraving many kinds of materials.This includes custom-made gifts, production branding, marketing, industrial markings, and much more.

● Efficiency

Laser engraving machines come with precise engraving and fast engraving speed,which makes working process more efficient than traditional egrave.and it can work 24 hours all the time.This quality allows it to be used for businesses in their mass production in faster time.

● Customization

Laser marking machine allows for customization. This allows users to make anything they want on any type of material. Moreover, this feature is considered best for businesses who are looking for customized business marketing products, retailers who are looking for custom-made gifts, and individuals who want aesthetic keepsakes.

● Non-Contactless

When laser machine start working,you just need to put your items in a suitable position,laser engraving does not require touching the object while engraving patterns. This, therefore, reduces the chances of product damage. Thus Enabling it to offer durable products

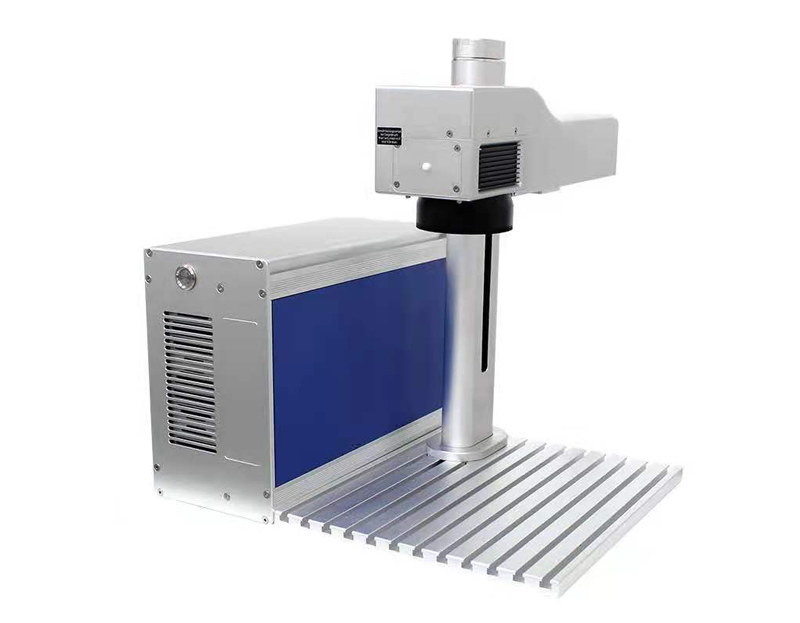

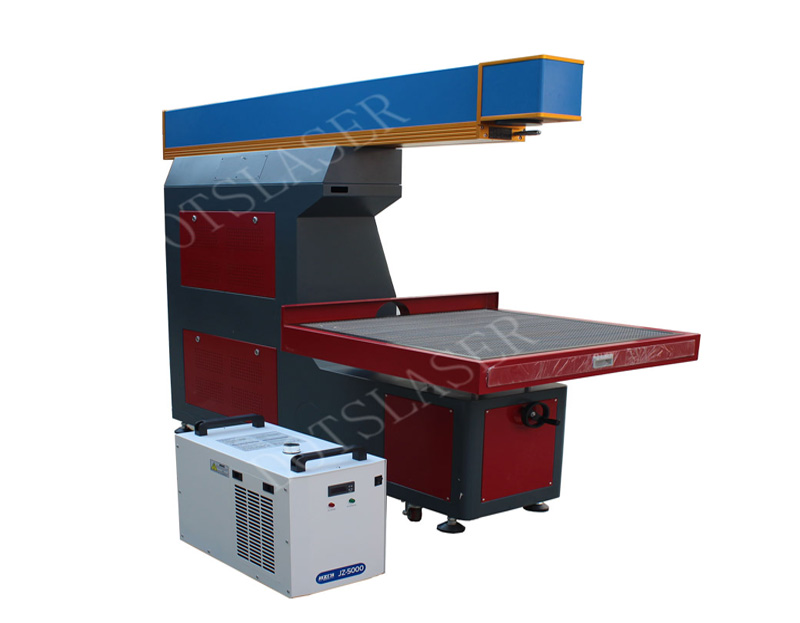

Machine parameters

| NO. | Name | DS-LM60 |

| 1 | Power | 2 KW |

| 2 | Weight | 1500 kg |

| 3 | Voltage | 380v 50/60hz |

| 4 | Engraving Area | 700*900mm |

| 5 | Mode of Operation | Continuous Wave |

| 6 | Laser Source Brand | DOTS |

| 7 | Laser Processing Accuracy | 1 Wire (0.01mm) |

| 8 | After-sales Service Provided | Online support |

| 9 | Video Outgoing-inspection | Provided |

| 10 | Machinery Test Report | Provided |

| 11 | Cooling | Air cooling |

| 12 | Warranty | 1 year |

| 13 | Size(length * wide * height) | 3190*1725 * 1500mm (Customized) |

| 14 | Graphic Format Supported | AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

| 15 | Applicable Material | Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wood |

| 16 | System Language | CN/EN/ES/PT Other Support Customization |

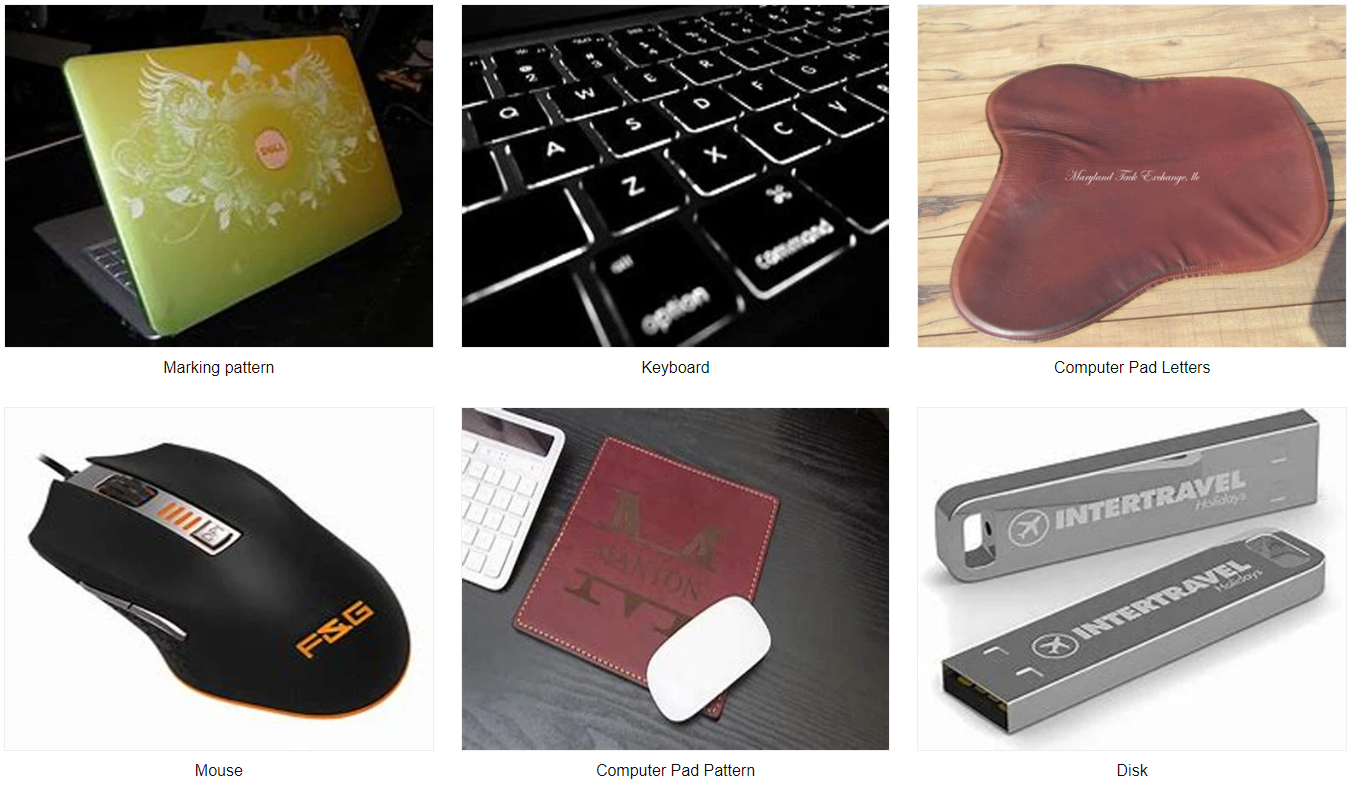

Samples:

Laser engraving offers sophisticated solution,a lot of people prefect unique customization.This technique can create detailed designs, logos, and text on devices, making them more visually appealing and functional. Key benefits include:

Branding: Engrave your company's logo on your products,ensure product unique feature.

Security: Engraving serial numbers or identification marks on items can help prevent theft. It can also make it easier to recover lost or stolen items.

Personalization: Users can create unique, one-of-a-kind devices with special messages, quotes, or custom designs.

What's the procedures when using laser machine?

Step 1: Check the Equipment

First,you should do well th pre-work when you use the machine,adjust the focusing distance,turn on the power,and the started the machine to engrave. please remenber the equipment is securely placed, prevent movement during the engraving process,otherwqisw it will cause engraving bad effect or safety problems.

Step 2: Select a Design

Select what your favorite patterns,logo or text to be engraved and enter it into the software,our software through file controls where the laser beam goes to make sure the design is accurately created on the machine's surface.

Step 3: Machine Setup

Before engraving adjusting the speed, power, and focus of the machine based on the material and design complexity to achieve optimal results,then engraving effect is more suitable on your laser marking object.

Step 4: Engraving Process

The engraver is started and the laser beam etches the design into the surface of the device. The laser removes material layer by layer, creating a permanent mark that is both beautiful and durable.

Step 5: Post-Engraving Care

Laser engraving is the process of selectively removing microscopic layers of material, thus creating visible marks on the treated surface. After engraving, the device is removed from the machine. It is then cleaned to remove any leftover residue from the engraving process.

Machine main components

Certificate

After sales services

1. Quality assurance and after-sales service

The warranty period of the equipment shall be 12 months since the equipment be used by the customers,

the installation and debugging is completed and the equipment is accepted by the demander.

Dotslaser attaches great importance to the after-sales service work of the product, once the product is delivered to the user,

the company immediately established the user after-sales service file,

and regularly track the user's product use status, solve and answer all the problems of the user,

received the user's notification information about the equipment failure,

the company's workers can make a rapid response within 2 hours. If the telephone guidance is difficult to troubleshoot,

our company's technical staff can arrive at the customer site within 24 hours to provide support.

2. Installation and debugging

Before machine installation, our factory will offer you a basic structure installation file,the good need 2 weeks delivery to you there ,

the engineers of Dotslaser will arrive at your site and inspect the machine again.

Comfirm all the conditions meet the installation and commissioning requirements of the equipment, the equipment will transport in time.

The installation and commissioning time of the equipment is about five working days, the first three days are connected to the use of the system,

and the system is operational after the service project.

The engineer will train qualified operators on basic maintenance procedures and general operating characteristics of the equipment in the next two days

3. Service support

If there has any problem with any part of the system during the warranty period, Dotslaser well-trained service engineers are ready to provide

cellphone call or begin on-site service,

if the machine has any problem during the warranty period,please contact us directly !