Laser Removing Paint Machine

Laser paint removal or ablation is a process during which functional layers are selectively removed from a surface using laser radiation (usually pulsed). The absorbing material is heated by laser energy and evaporates or sublimates. The transparent material is ablated in its solid state.

Video shows:

Laser paint removal is a process that uses high-intensity laser beams to strip away layers of paint from surfaces. This method of coating removal is both precise and controlled, so it's ideal for applications where traditional methods, like chemical stripping or abrasive blasting, might cause damage or be less effective.

Benefitd of laser paint removal

01/Less processing Waste

Laser paint removal less hazardous than traditional machine. Since lasers vaporize paint directly from the surface with no need for chemicals or abrasives, this method produces almost no secondary waste.

02/Engraving precisely

Laser removing well control while procesing,well protect to your materials. You can adjust the laser's intensity and focus to target specific layers of paint without damaging the material underneath the coat of paint.

03/Efficient and Cost-Effective

Laser paint removal is faster and more efficient than conventional methods. There's less setup time and you can strip paint, depending on the power of your laser and how thick the paint is.

04/Wide applications

It can be used on a wide range of materials, including metal, plastic, and composites, without causing damage. Laser systems are also quite low-maintenance, with fewer consumables and only occasional servicing compared to traditional paint removal equipment.

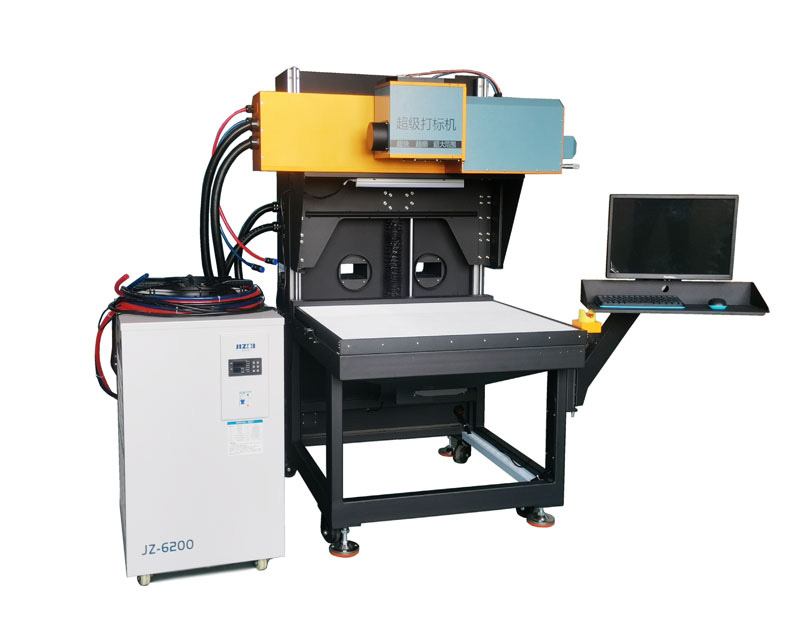

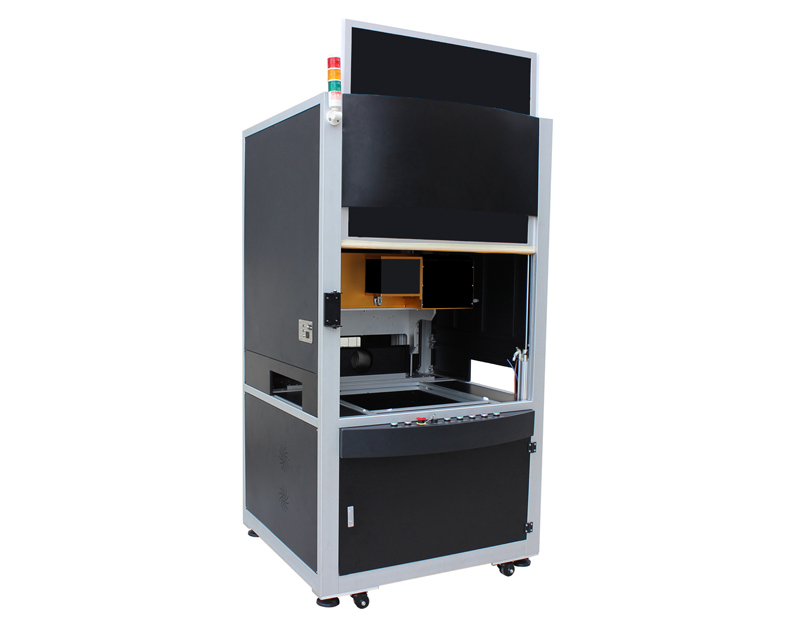

Machine parameters

NO. | Name | Laser Engraving Automotive Parts |

1 | Model | DS-LM30 |

2 | Power | 5.5KW |

3 | Voltage | 380v 50/60hz |

4 | Engraving Area | 700*900mm |

5 | Mode of Operation | Continuous Wave |

6 | Laser Source Brand | DOTS |

7 | Laser Processing Accuracy | 1 Wire (0.01mm) |

8 | Cooling | Air cooling |

9 | Size(length * wide * height) | 3190*1725 * 1500mm (Customized) |

10 | Graphic Format Supported | AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

11 | Applicable Material | Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wood |

12 | System Language | CN/EN/ES/PT Other Support Customization |

13 | Laser Type | Fiber Laser |

14 | Marking Depth | 0-1mm |

15 | Marking Speed | 0-7000mm/s |

16 | Weight | 1500 kg |

Laser Cleaning vs. Sandblasting

Sandblasting uses abrasive materials, like sand or glass beads, propelled at high speed to physically scrape paint off the surface. In contrast, laser cleaning is a non-contact method that uses focused laser beams to vaporize the paint without actually touching the underlying material.

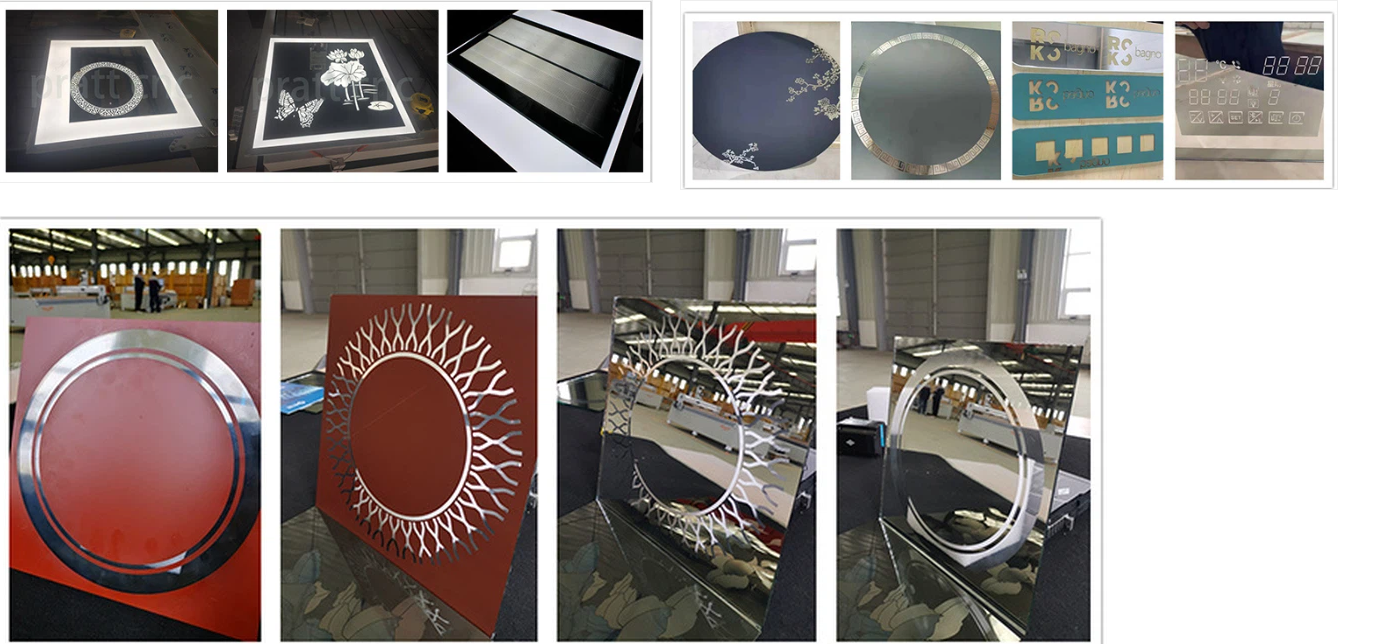

Applications:

Samples:

Some tips When Buying a Laser

Tip 1: Set A Realistic Budget

When you want to purchase a laser machine,based on your realistic budget.These include maintenance costs, the energy efficiency of the device and any repair costs. A thoroughly calculated budget helps to avoid unexpected expenses and ensure that the project remains financially viable.

Tip 2: Define The Area Of Application

Ensure what would you use the machine do, it is therefore important to know exactly what tasks the laser should perform before purchasing. This clarity makes it much easier to select the right model.

Tip 3: Define Performance And Working Range

A powerful laser is important for fast and precise cuts or engravings. The working area should be large enough to easily process the desired materials and projects. It is advisable to be aware of the specific requirements and technical specifications before making a decision.

Tip 4: Select The Laser Type

There are different types of lasers, each of which is suitable for certain materials and applications. Choosing the right type of laser is crucial for the efficiency and effectiveness of the investment.

Tip 5: Maintenance, Service And Additional Services

Reliable customer service is essential in the event of a malfunction. Before making a purchase, you should therefore clarify which services the manufacturer offers.

This includes the availability of spare parts, the regularity of maintenance and the response time of customer service.

Shipment and Package

Certificate: