Laser Sandblasting Mirror Machine

Glass sandblasting machines are used for surface processing of glass. They work by propelling fine abrasive particles, typically sand, at high speed onto the glass surface,Sandblasting is a fast and efficient way toaltering its texture and appearance create etched designs on glass for privacy or decorative purposes.

Video shows:

Machine's features

Versatile usage

1.This machine integrates coating removal, sandblasting, and drilling functions into one, eliminating the need for separate processes.

It streamlines the transformation of mirrors into sandblasted effects without the necessity of removing films or applying frosting coatings.

Precise Engraving

2. The machine ensures precise processing of patterns such as large rectangles, squares, circles, etc., maintaining straight lines and preventing

any dislocation from occurring.

Fast speed

3. Integrating the functions of coating removal,sandblasting, drilling ,processing fast, one step completion.

Saving Cost

4. Sandblasting no pollution, reduce labor costs,maintenance-free, it saves production costs and increases efficiency,save processing time and labor cost.

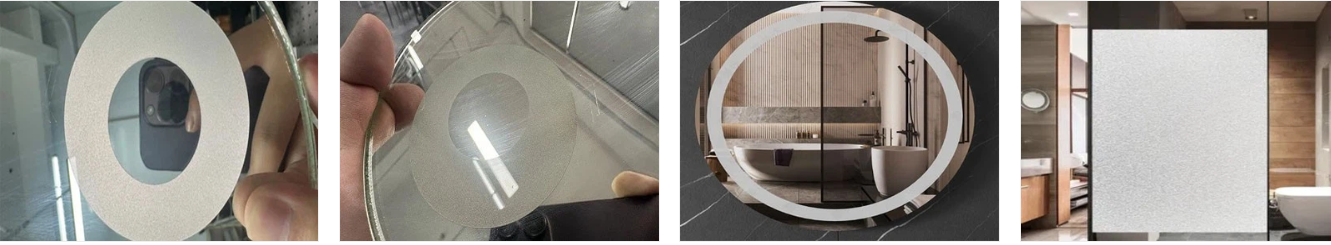

1. Logo and pattern engraving: Laser marking machines can be used to engrave logos, patterns, text and other information on the surface of smart mirrors.

2. Touch button marking: Through laser marking technology, the location and function of the touch buttons can be marked on the surface of the smart mirror, users can easily find differrent functions.

3. Sensor calibration: The sensor inside the smart mirror can be calibrated through laser marking technology to ensure that it accurately senses the user's operation and environmental information.

4. Decoration: Laser marking technology can be used to create exquisite textures, patterns or decorative effects on the surface of smart mirrors to enhance the look and feel of the mirror, making it more attractive and personalized.

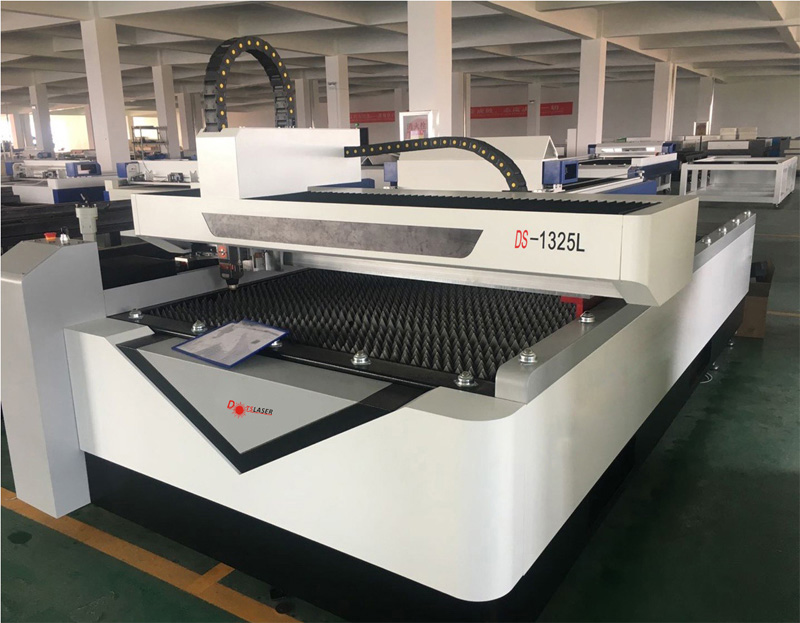

Machine parameters

NO. | Name | Laser Engraving Automotive Parts |

1 | Model | DS-LM30 |

2 | Power | 5.5KW |

3 | Voltage | 380v 50/60hz |

4 | Engraving Area | 700*900mm |

5 | Mode of Operation | Continuous Wave |

6 | Laser Source Brand | DOTS |

7 | Laser Processing Accuracy | 1 Wire (0.01mm) |

8 | Cooling | Air cooling |

9 | Size(length * wide * height) | 3190*1725 * 1500mm (Customized) |

10 | Graphic Format Supported | AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

11 | Applicable Material | Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wood |

12 | System Language | CN/EN/ES/PT Other Support Customization |

13 | Video Outgoing-inspection | Provided |

14 | Machinery Test Report | Provided |

15 | Weight | 1500 kg |

16 | Warranty | 1 year |

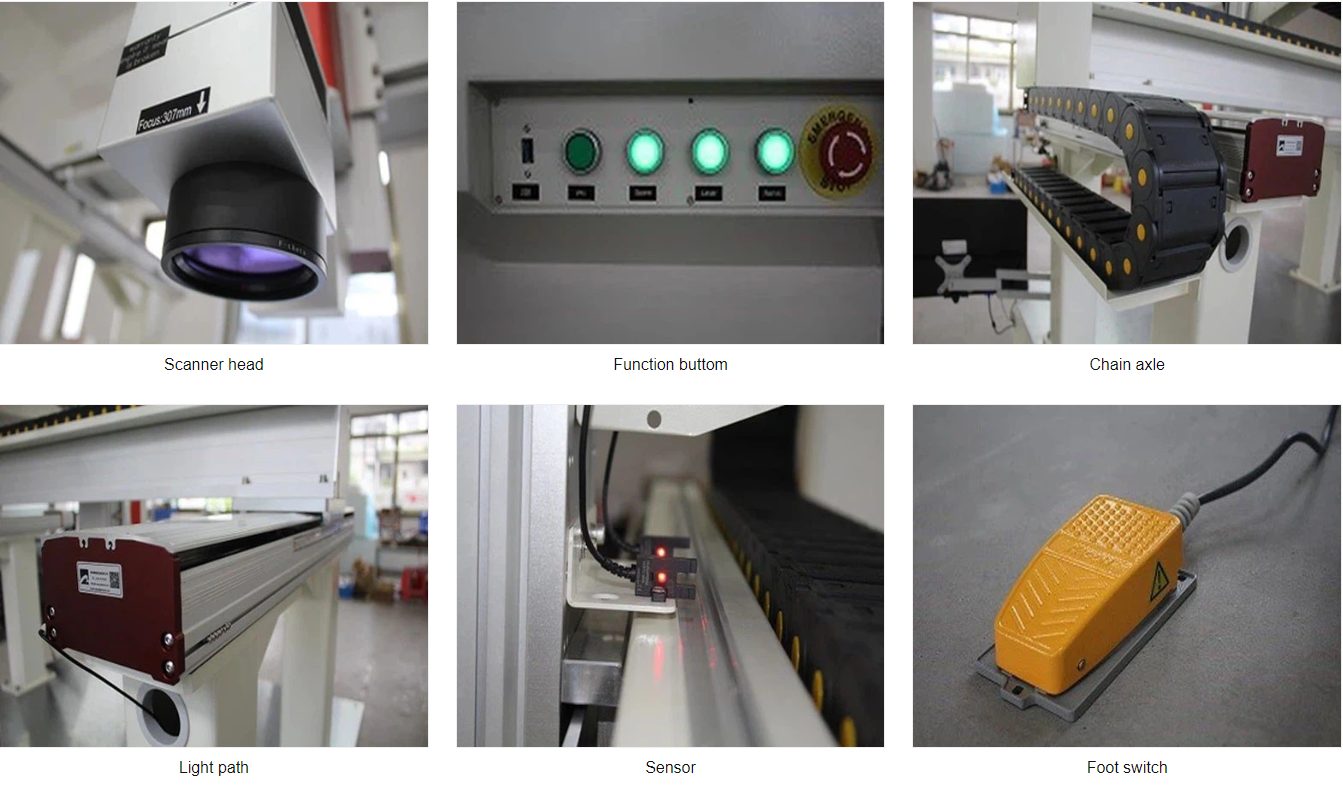

Main machine structure:

Samples:

How to choose the right type of mirrors?

1. Purpose: Think about the mirror's purpose (e.g., full-length, wall, or round mirror).

2. Size: Choose a mirror that's about the same width or slightly smaller than your bathroom vanity.

3. Style: Match the mirror to the room's aesthetic (e.g., modern or classic).

4. Placement: Consider the height and width of the mirror in relation to the wall or furniture.

How To Set up Your Laser Engraver for Mirrors?

1. Choose the right mirror - Choose the smooth mirror and suitable size.

2. Create your design- Before you engraving,choose you favorite patterns.

3. Set up your laser- Adjust the speed, power, and frequency settings until you get the desired results.

4. Engrave your design- Once your laser is set up and the mirror is prepared, you can start engraving.

6. Clean the mirror - After engraving, clean the mirror to remove any residue or debris from the process.

Shipping and package

FAQ

Q1: How does the package?

A: Dotslaser provides 3 layers package. For the outside, we adopt wood craft case. In the middle.the machine is covered by foam, to protect the machine from shaking. For the inside laser machine,

the machine is covered by thickening plastic bag for waterproof.

Q2: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and ourshipping agent have full experienced in safe transportation. We have exported to 100 countries worldwide.

So please don't worry, you will receive the parcel in good condition.

Q3: How to install and run the machine?

A:Our worker will install all the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine 95% customers can learn by themselves.

Q4: How can i do if the machine goes wrong?

A: lf confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we

can to solve it for you.