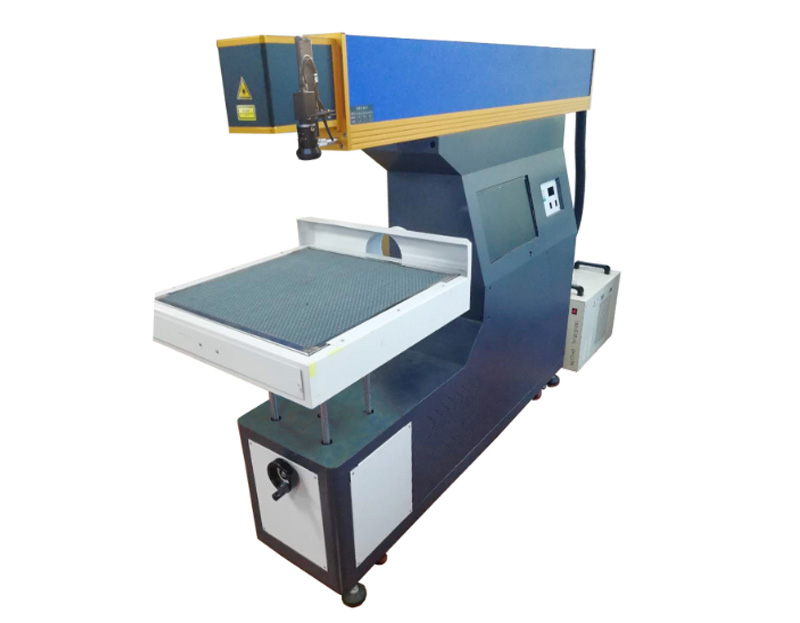

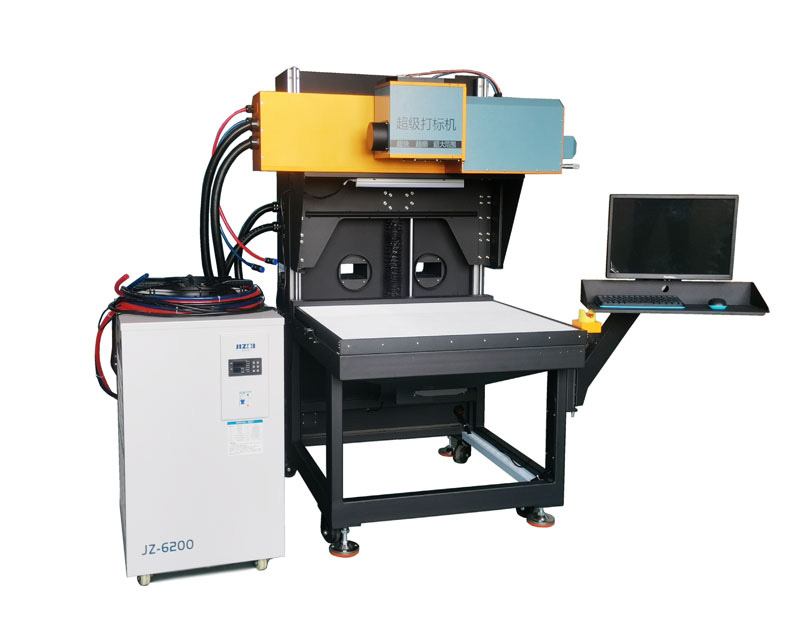

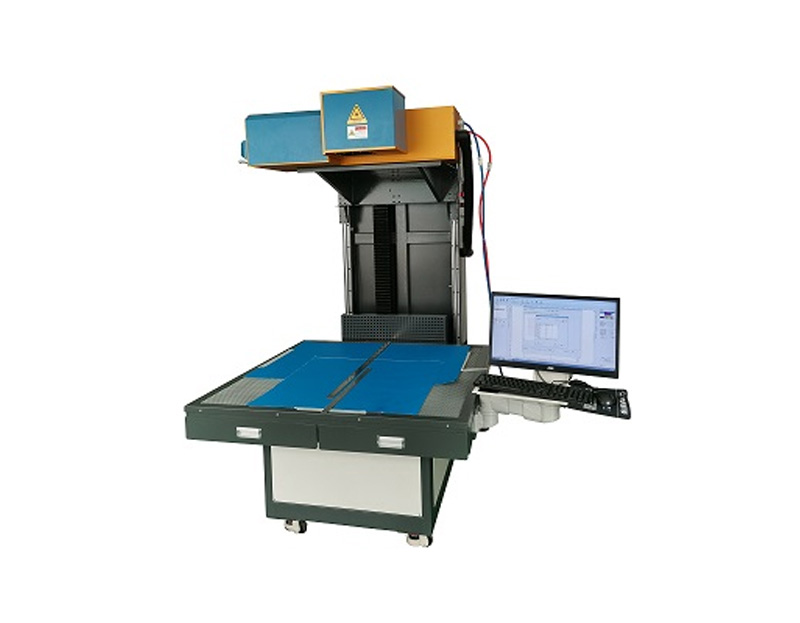

LED lights laser marking machine

Laser marker enables led lamp manufacturer customers that could marking and printing Logo and words on the surface of the LED Lamp and Bulbs.The machine is equipped with eight rotary fixture stations. Through the way of station rotation and fixture revolution, it can mark automatically and do current detection for the LED lamp.The marking effect is clear, beautiful and permanent.

Video shows:

Machine's features

01/Long lifetime:

Laser source life reaches 100,000 hours, ensuring consistent performance.

02/Friendly environment:

No waste consumables ,no pollution to the environment,easy to operate ,friendly to green hands.

03/Versatile usages:

Capable of marking on a wide range of materials, including metals, plastics, ceramics, glass, and more.

04/Engrave precisely and fast speed:

Laser technology allows for detailed, high-speed marking, ideal for both flat and curved surfaces.

parameter

| NO. | Name | DS-LM200 |

| 1 | Power | 2 KW |

| 2 | Weight | 1500 kg |

| 3 | Voltage | 380v 50/60hz |

| 4 | Engraving Area | 700*900mm |

| 5 | Mode of Operation | Continuous Wave |

| 6 | Laser Source Brand | DOTS |

| 7 | Laser Processing Accuracy | 1 Wire (0.01mm) |

| 8 | After-sales Service Provided | Online support |

| 9 | Video Outgoing-inspection | Provided |

| 10 | Machinery Test Report | Provided |

| 11 | Cooling | Air cooling |

| 12 | Warranty | 1 year |

| 13 | Size(length * wide * height) | 3190*1725 * 1500mm (Customized) |

| 14 | Graphic Format Supported | AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

| 15 | Applicable Material | Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wood |

| 16 | System Language | CN/EN/ES/PT Other Support Customization |

Samples:

1.Laser marking on light bulb

2.Laser marking on special shapes lighters

Laser marking machine:

1. Laser marking does not need to consume any consumables, customers don't have to worry about because of increased production and raise the cost of consumables,

2. Zero consumables of permanent marking form can be processed goods shall not alter the characteristics of effective prevent competitors want to deliberately to change the product information of chances.

3. Long lasting marking enhance the trust of customers for the product, and brand. Suitable for LED lights need to fine the underlying demand.

Traditional ink marker method:

1. Using special ink consumable materials, the cost of consumables as demand and rising

2. Ink marker using regular encountered in the process of ink plug nozzle, need to hire a professional maintenance personnel,it will increase labor cost.

3. Ink marking is easy to clean, and the effect of the tag is easy to be rivals have altered, memory affect product credibility and the brand reputation of the enterprise

Shipment and Package

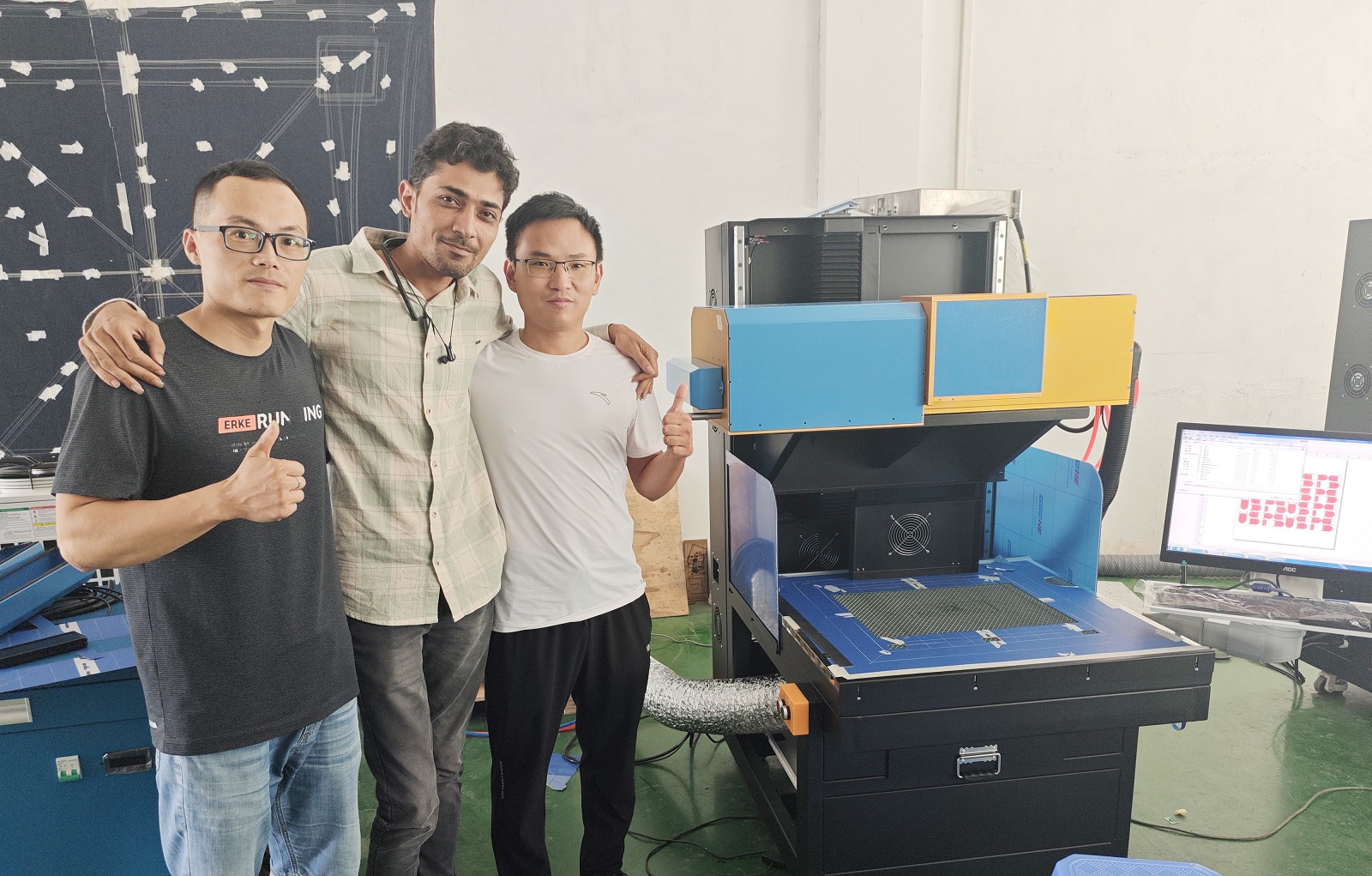

Customer's feedback

1. Quality assurance and after-sales service

The warranty period of the equipment shall be 12 months since the equipment be used by the customers, the installation and debugging is completed and

the equipment is accepted by the demander. Dotslaser attaches great importance to the after-sales service work of the product,

once the product is delivered to the user, the company immediately established the user after-sales service file,

and regularly track the user's product use status,solve and answer all the problems of the user, received

the user's notification information about the equipment failure, the company's workers can make a rapid response within 2 hours.

If the telephone guidance is difficult to troubleshoot, our company's technical staff can arrive at the customer site within 24 hours to provide support.

2. Installation and debugging

Before machine installation, our factory will offer you a basic structure installation file,the good need 2 weeks delivery to you there ,

the engineers of Dotslaser will arrive at your site and inspect the machine again. Comfirm all the conditions meet the installation

and commissioning requirements of the equipment, the equipment will transport in time.

The installation and commissioning time of the equipment is about five working days,

the first three days are connected to the use of the system, and the system is operational after the service project.

The engineer will train qualified operators on basic maintenance procedures and general operating characteristics of the equipment in the next two days.

3. Service support

If there has any problem with any part of the system during the warranty period, Dotslaser well-trained service engineers are ready

to provide cellphone call or begin on-site service, if the machine has any problem during the warranty period,please contact us directly !