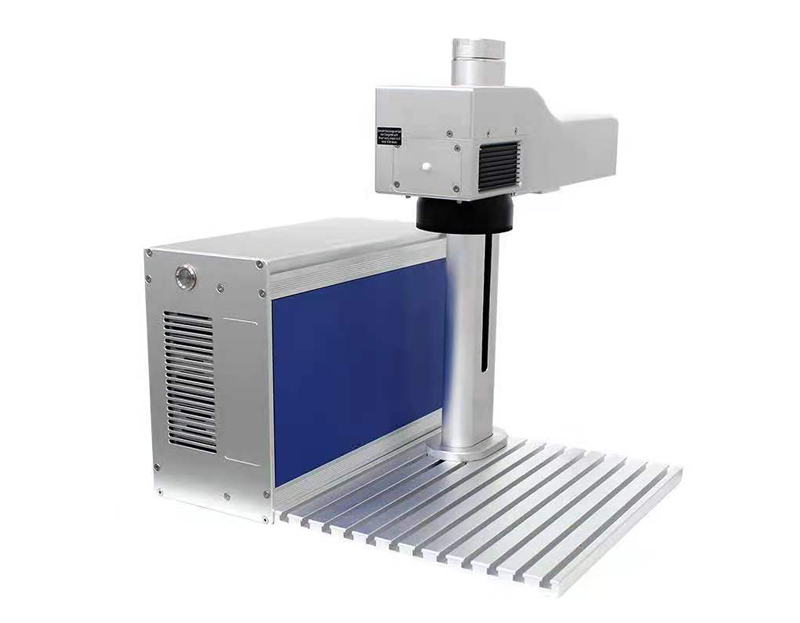

Spilt small fiber laser engraver

One of the significant advantages of these machines is their compact size. They are small enough to fit on a desktop, making them suitable for small businesses or even hobbyists. They are easy to set up and require minimal maintenance, making them a cost-effective option in the long run. Also, they are environmentally friendly since the lasers do not emit harmful fumes or radiation.

Video shows:

Mchine's features:

1.Compact design

The small fiber laser marking adopts modular design, stable performace with long lifetime, lighweitht machine, easy to carry and move to outside operations, no space limited,suitable for small store, small office and outdoors working.

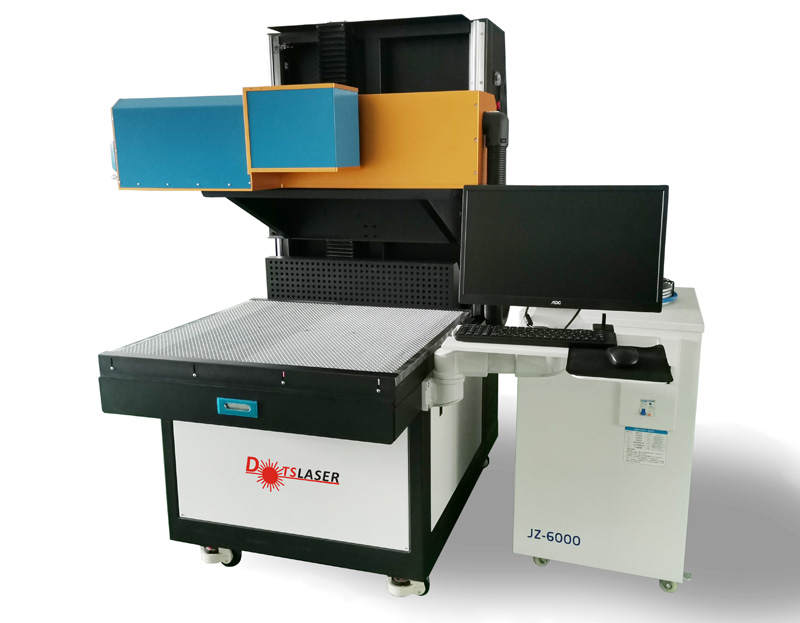

2. Power laser source techniques

It is equipped with 1064 nm wavelength fiber laser source, it has wide range of applicable materials, such as metal, aluminum, steel, stainlesss steel. Some non- metallic like PC、ABS、PVC、PC+ABS. It has wide applications in automobile accessories industries, electronic parts and components, 3C,PC, hardware, building, jewelry industries, etc,.

3. Economic design

Maintenance free, 1 year warranty. Stable processing, long lifetime, versatile functions with good price, it is a economic machine specially design for customer.

4. Easy operation

Versatile control software system, support various languages, esay to use, Support many kinds of format, such as Bar code,QR code, text, images, serial numberrs, 24 hours continous processing, save a lot of labor cost and processing cost.

Parameter

Model | MZF-20A | MZF-30A | |

Laser parameter | Laser source model | MFP-20X/ 20QS | MFP30X/3QS |

Output power | 18.5/20-W | 30W | |

Laser beam quality M2 | ≤1.4 | ≤1.4 | |

Pulse repeat frequency | 27-60KHZ | 30-60KHZ | |

Wavelength | 1.064±5nm | ||

Output power stability | <3% | ||

Lifetime | About 100000 hours

| ||

Optical | Marking range | 100-150 mm (optional) | |

Marking depth | ≤1mm(depends on power and time) | ||

Marking accuracy | ≤10000mm/s | ||

Marking repeat accuracy | ±0.002 | ||

Mini. Line width | 0.1mm | ||

Mini. characters height | 0.15mm | ||

Use environments | Cooling way | Air | |

Power supply | 500W / 220V / 50Hz(can be choose 110V)

| ||

Temperature/ humidity | 0~40°,30% RH 85%

| ||

Oil condensation | Not allow | ||

Other parameter | Operate system | Windows | |

File format | Windows operation system all characters | ||

Size | Cabinet 350x160x270mm Marking machine:390x300x470mm | ||

Packing size | 550x270x680mm | ||

Weight | About 20kg | ||

Application settings:

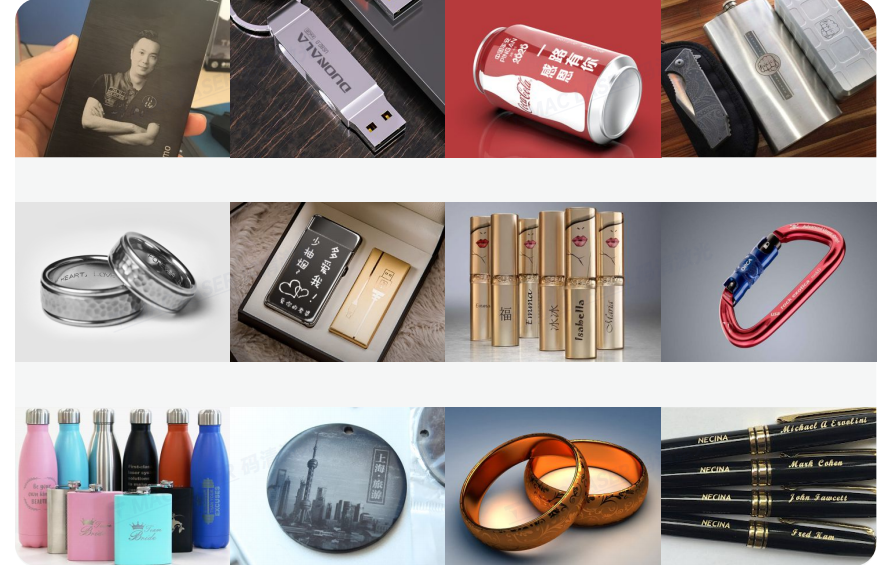

Samples

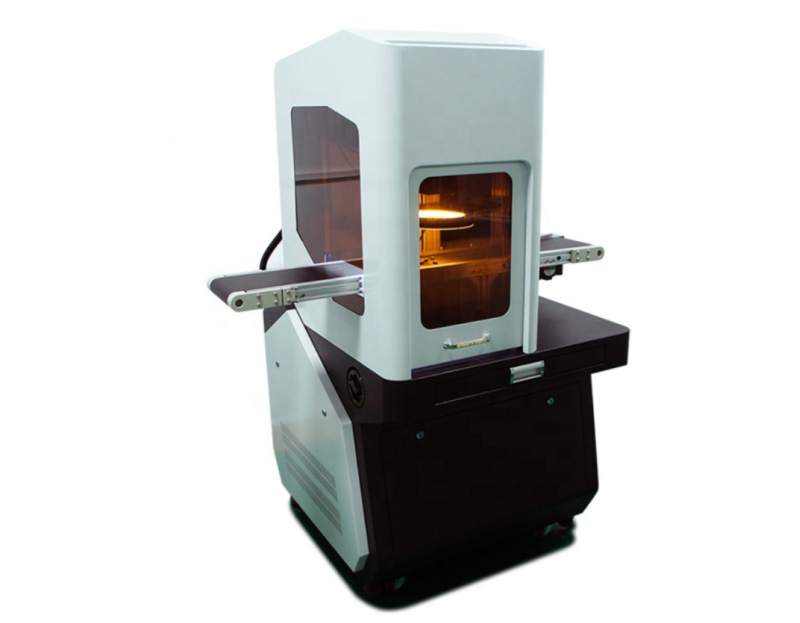

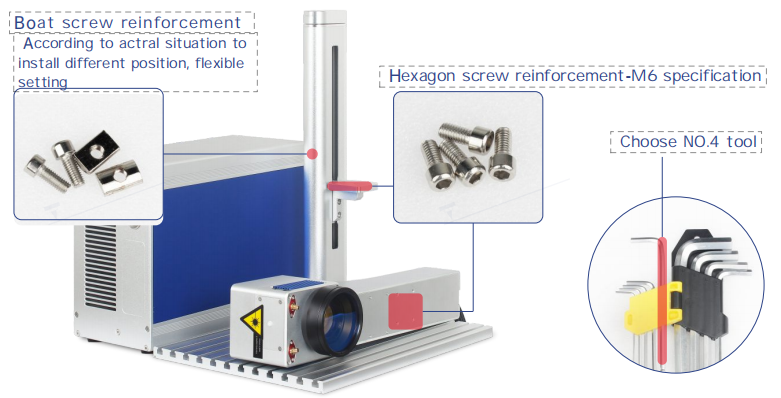

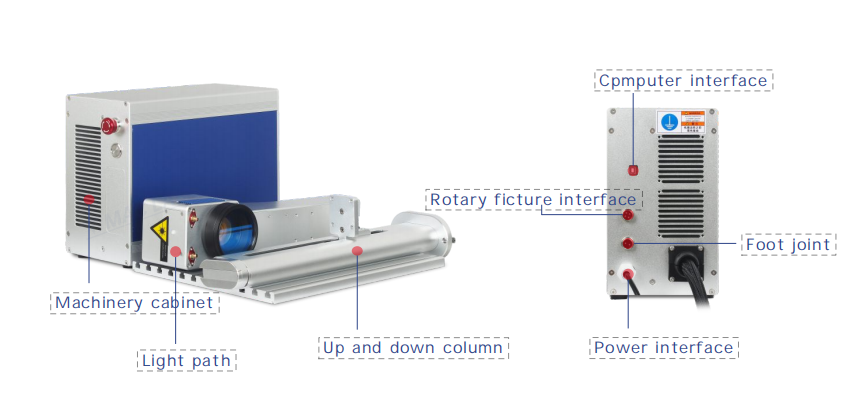

Product install

1.Accordimg to the graph. you can install fiber laser marking easily.

2. Know more about machines, master it in short time.

Shipment and package

Certificate

FAQ

Q1. How to choose a reliable laser machine?

A: Before you buy a laser machine, you have better to do a research. Look for reputable manufacturers or suppliers who have a proven track record of delivering high-quality laser machines. Check out their website, reviews, and ratings to ensure they have a good reputation in the industry.Dotslaser is a professional laser machine company, if you want to buy laser machine, we can offer you some professional suggestions.

Q2: Will laser marking machine damage the materials?

A: As a professional and advanced technology, it adopts non-contact engraving process, which means that there is no direct contact with the materials.Therefore, the material is not damaged during the marking process. The laser beam is controlled by a computer system that can adjust the intensity, speed, and direction of the beam to mark on different materials with precision, consistency, and clarity.

Q3: What materials can be laser mark?

A: Fiber laser usually mainly mark on metal, aluminum, steel, stainless steel, uv laser mainly engrave on glass, smart chip or other delicate marking materials, CO2 laser marking machine has wide applicable materials, such as plastic, wood, stone, paper, bamboo, rubber,leather and so on.

Q4: What is color laser marking?

A: Color laser marking is a method of creating permanent marks on a variety of materials such as metal, plastic, glass, paper, and more by utilizing a laser beam. The laser beam is directed at the surface of the material, which evokes a reaction resulting in the appearance of a mark or design. The major advantage of color laser marking is the ability to produce vibrant, high-quality images in a variety of colors.