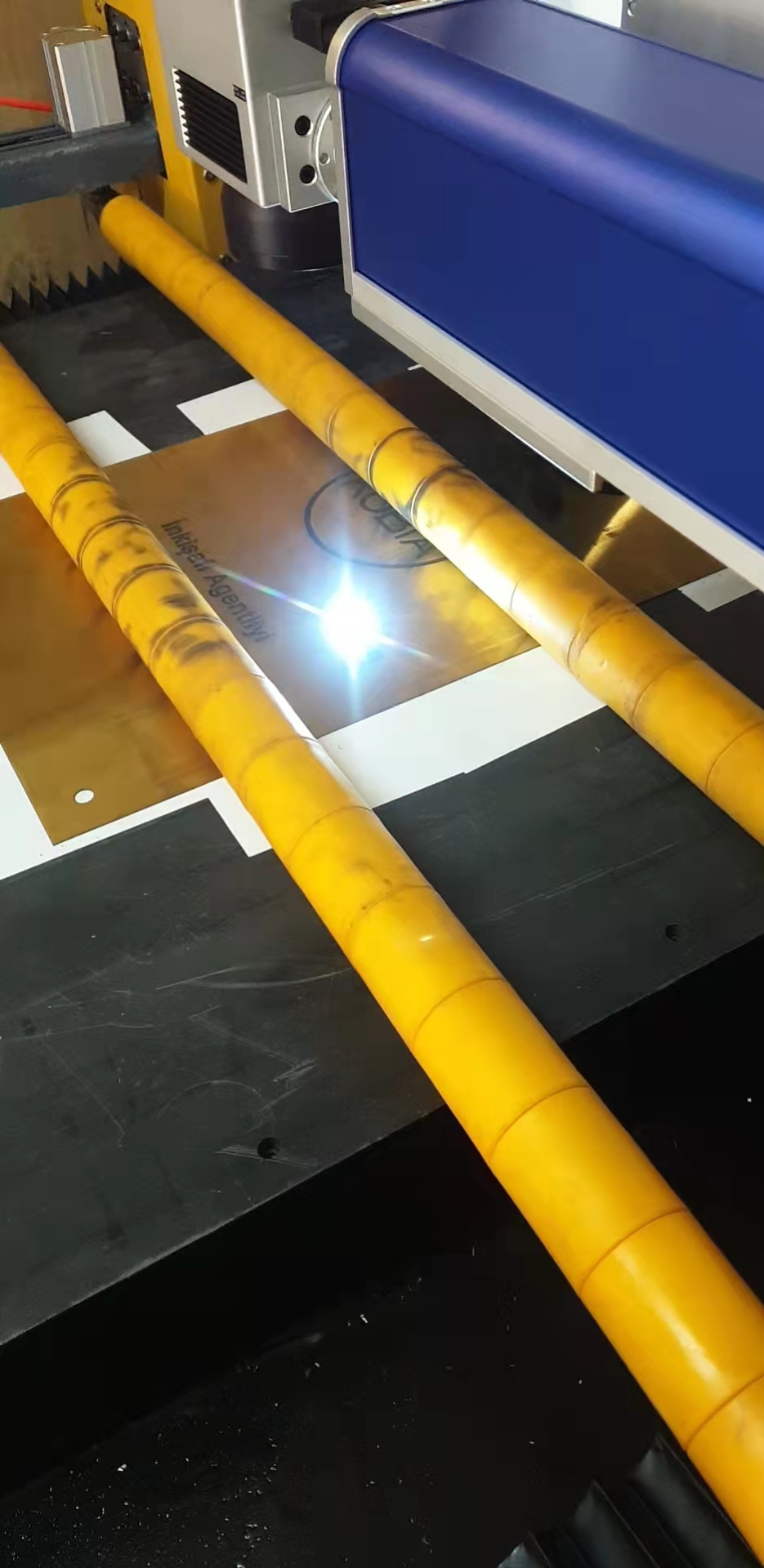

Super large engraving for mirror

Large format fiber laser marking tool has a wide range applications, it is suitable for marking metal products and some non metallic materials products. Large format fiber engraver also suitable for sandblasting on the mirror, it did a good feedback on the mirror, customers all like this techniques! It's a good choice for mass production in the industry. Saving labor cost and processing time, precise and permanent marking is warmly welcomed in the laser processing market, which can increase productivity greatly, it is great helpful in your business!

Video shows:

Machine's features

1. Large workpiece

This large format fiber laser engraver has equipped with super large workpiece ,which is suitable for mass productions,increase productivity greatly, saving lots of processing time and labor cost, non contact engraving method, no consumables and friendly to environment.

2. Precision and efficiency

Super large format laser engraving machine equipped with high quality laser source, high speed galvo scanning system, it ensures perfect marking and higher process efficiency by using laser technology.

3. Cost effective

In CNC metal marking, no mold is required, saving a lot of the cost of producing and fixing molds.easy to operate,and it is suitable for continuous production, the machine owned automatic marking technology, mass production increase productivity,

Parameter

Name | Large area super fiber engraver |

Laser type | Fiber laser |

Cooling mode | Air cooling |

Marking area | 1000x1000mm, 1300x1300mm,1300x2500mm, 2500x6000mm. |

| Mode of operation | Continuous wave |

| Applicable material | Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wood |

Core component | Laser source |

Feature | Deep marking |

Working temp

| 0~40℃

|

Applicable industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other |

Warranty | 1 year |

| System language | CN/EN/ES/PT Other Support Customization |

Adantages of CNC laser machine system:

The combination of laser machining system and computer CNC technology can constitute high -efficiency automation processing equipment , which can make various texts, symbols, and patterns. High -efficiency, fast -paced requirements. Laser marking machine uses laser beams to make permanent marks on various material surfaces. The effect of the marking is to reveal deep substances through the evaporation of the surface material, or "engraved" traces through the chemical physical changes of the surface material, or burn some substances through the light. Patters, text.

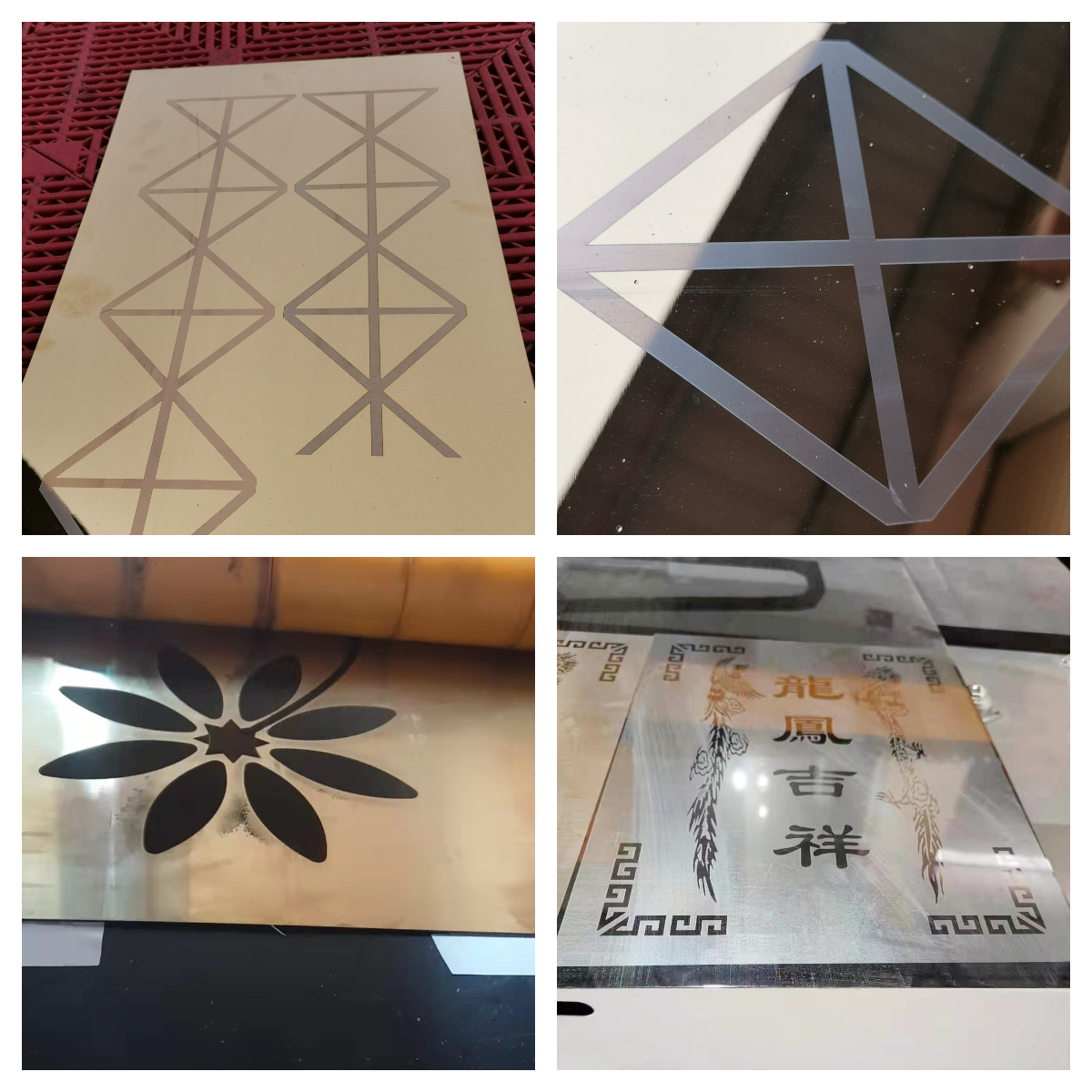

Samples

Why we use large format fiber laser machine for marking?

1. Stable performance, marking characters won't cause deformation.

2. High uniformity, smooth workpiece ensures objects received laser all the same, won't happened somewhere marking with deep color and others with light color.

3. Adapts high quality laser source, output perfect laser beam, ensures excellent marking.

4. The system adopts single-axis linkage control, and there is no joint in the transverse or longitudinal area.

5. This large format marking machine is equipped with a servo motor control, ensures precise marking, high speed galvo scanning system, which can up to 8000mm/s, fast process speed, thin and delicate marking lines.

6. International standard electronic control system, ensures whole machine stable operation, dicrease process problems.

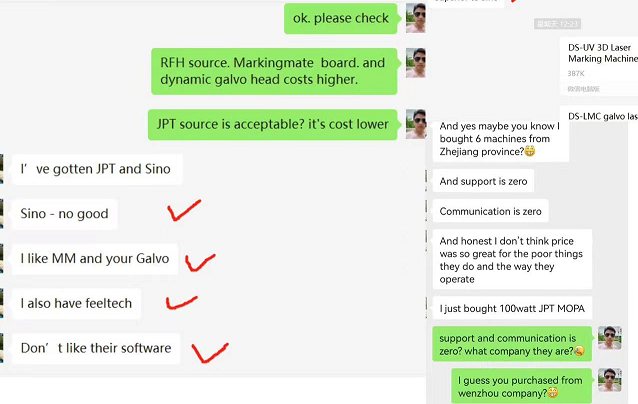

Customer's feedback

Sandblasting techniques

→Sandblasting is used to remove paint,rust debris, scratches and casting marks from surfaces but it can also achieve the opposite effect by etching surfaces to increase products's texture and design.

How does the sandblasting process work?

1. Sandblasting is a process in which a jet of fine sand or other abrasive material is propelled at high speeds onto a surface to clean it or make a new texture. This process is commonly used in industrial settings to remove unwanted coatings, rust, or other surface contaminants from machinery, equipment, or buildings.

2. The sandblasting process used to in cleaning surface. Any loose debris or dirt on the surface is removed, and the area is covered with protective materials to prevent damage to surrounding fixtures or surfaces. The sandblasting equipment is then set up and the abrasive material is loaded into the blasting tank.

3. Once the equipment is ready, the machine will directe a stream of compressed air through a nozzle that propels the abrasive material at high speeds onto the surface to be cleaned. The pressure of the abrasive material and the speed at which it is propelled ensure that any unwanted material is quickly removed from the surface.

4. During the sandblasting process, the operator adjusts the angle of the nozzle and the pressure of the compressed air to achieve the desired level of cleaning or texturing. The use of different types of abrasive materials, such as glass beads or walnut shells, can also be used to achieve specific surface finishes.

Shipment and package

Why choose us?

1. Our items mostly incorporate laser engraving machines series, laser cutting machines series, laser welding machines series, laser cleaning machines series, and so on. Laser types include: fiber laser, CO₂ laser, UV laser. We can also accept cases with customized needs, that means, OEM/ODM is an option.

2. Our business tenet is: "Customer First, Quality First, Reputation First". Customer's satisfaction is our greatest driving force. We always think about what customers think and what customers want, and provide customers with perfect products as much as possible to maximize their benefits. Our company locate in Guangzhou. The head company has been established for more than ten years and currently has its own branches and offices in many cities in China. The factory mainly faces the domestic market and many overseas countries, such as the United States, Colombia, Brazil, Germany, Italy, South Korea, India, Kuwait, Turkey, Malaysia, Australia, etc. The products are all designed, produced, sold, and after-sale by ourselves. With rich laser machinery manufacturing capabilities and perfect technical support levels.

3. Laser marking machines, laser cutting machines, laser welding machines, laser cleaning machine, Laser machines accessories.

Processing materials: metal materials, such as: stainless steel, steel, alloy steel, sheet metal, aluminum, anodized aluminum, gold, copper, silver, zinc, etc., non-metallic materials, such as: plastic products (ABS, PVC, PC Etc.), glass, leather, fabric, ceramics, cardboard, etc.