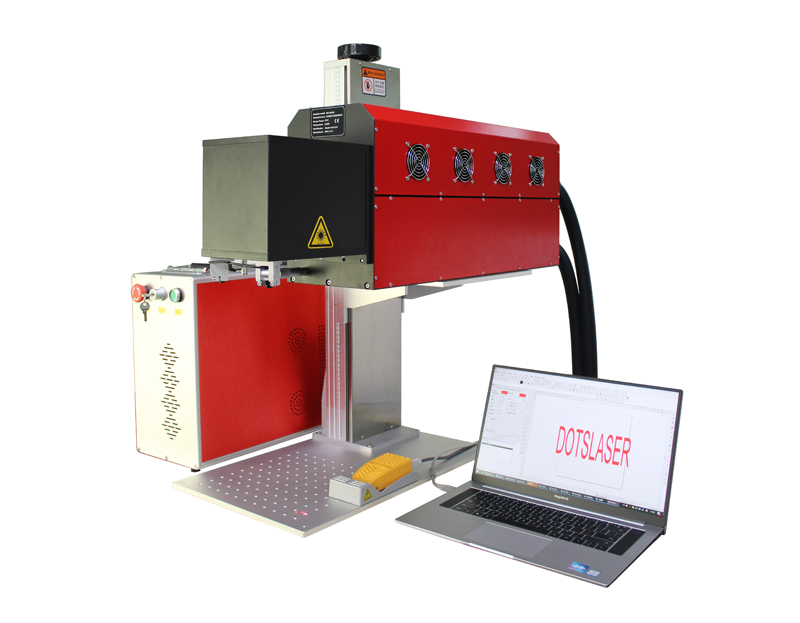

Wristwatch fiber laser marker

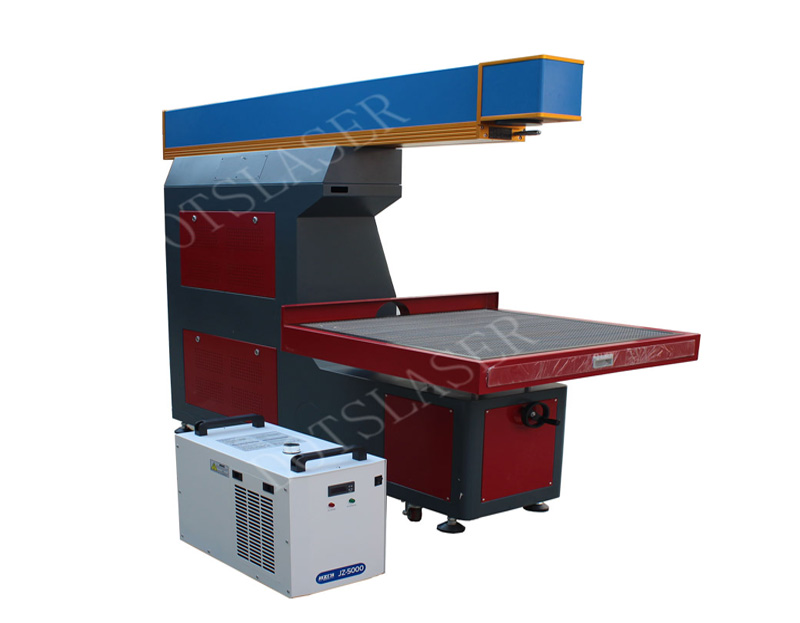

Fiber laser mchine is suitable for designing wristwatch, with its high precision and high efficient engraving, whatever text,images,patterns can be well engraved on wirstwatch.This big format engraving machine suit for mass production,not only increase processing productivity,but also save a lot of processing time and labor cost,it's a good soulution for marking wristwatch manufacturers, customized wristwatch for clients.

Video shows:

Advantages of fiber laser marker

Machine's parameter

| NO. | Name | DS-LM30 |

| 1 | Power | 2 KW |

| 2 | Weight | 1500 kg |

| 3 | Voltage | 380v 50/60hz |

| 4 | Engraving Area | 700*900mm |

| 5 | Mode of Operation | Continuous Wave |

| 6 | Laser Source Brand | DOTS |

| 7 | Laser Processing Accuracy | 1 Wire (0.01mm) |

| 8 | After-sales Service Provided | Online support |

| 9 | Video Outgoing-inspection | Provided |

| 10 | Machinery Test Report | Provided |

| 11 | Cooling | Air cooling |

| 12 | Warranty | 1 year |

| 13 | Size(length * wide * height) | 3190*1725 * 1500mm (Customized) |

| 14 | Graphic Format Supported | AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

| 15 | Applicable Material | Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wood |

| 16 | System Language | CN/EN/ES/PT Other Support Customization |

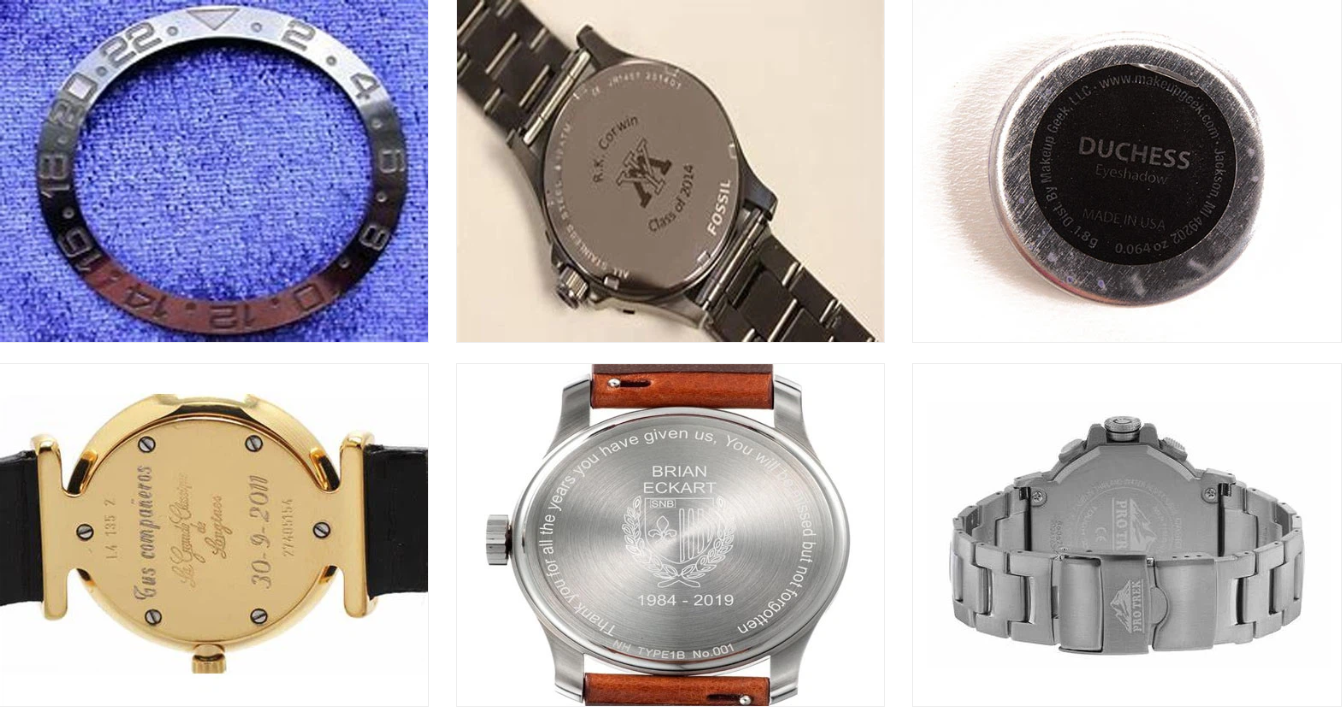

Engraving technology applies on wristwatch

There has two methods to compared with:

1. Traditional hand engraving:This involves the use of a sharpened tool to carve designs and text onto the watch surface. Hand engraving is a time-consuming and intricate process, but it produces intricate and detailed designs that are visually stunning.

2. Laser technology: Which is a more modern and efficient way of engraving watches. Laser marking can produce highly detailed and precise marking with speed and accuracy, resulting in a perfect finish for high-end watches.

How does laser machine to engrave wristwatch?

Engraving is one of the most delicate processes in watchmaking. In order to engrave a dial, the watchmaker uses a very sharp tool to carve the metal from the dial (or the part of the watch that is being engraved). In this way, he creates the desired pattern. You’ll be able to find many designs that feature scrollwork or florals as some of the most popular motifs. Sometimes, engraving is used to create greater depth and dimension to the existing engraved motifs of a watch. It is important to mention that engraving is an extremely time-consuming process! One slight mistake can ruin hours and hours of work, as no errors can be retraced or fixed. For this reason, engrave machine must with higher requirement,fast engraving speed and precise engraving is essential.

Some samples of laser engraving on wristwatch

Machine main components

Delivery routine

Certificate