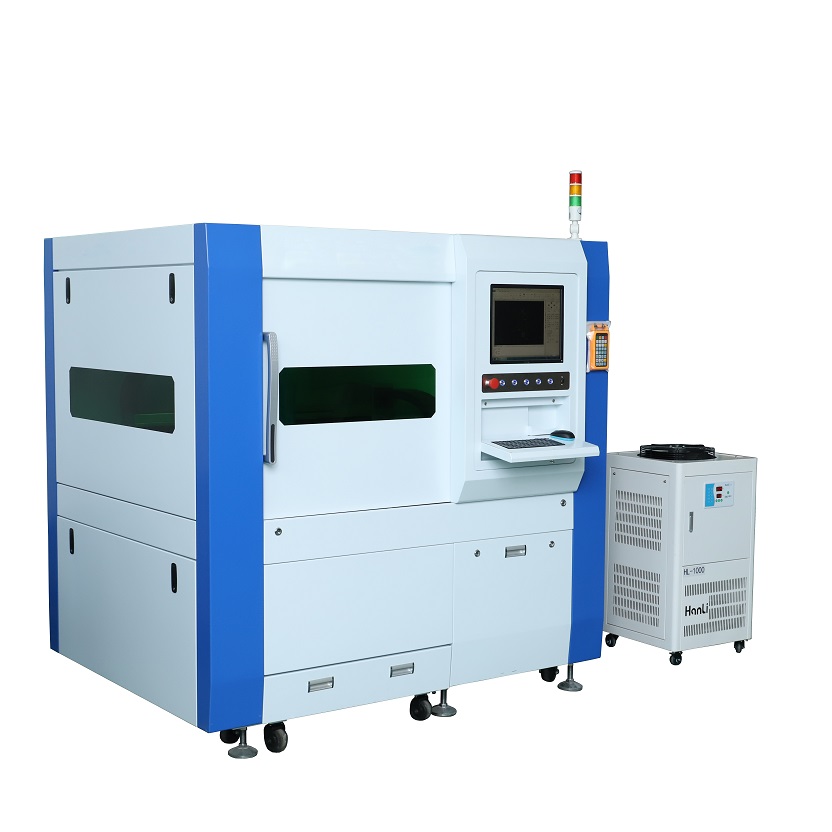

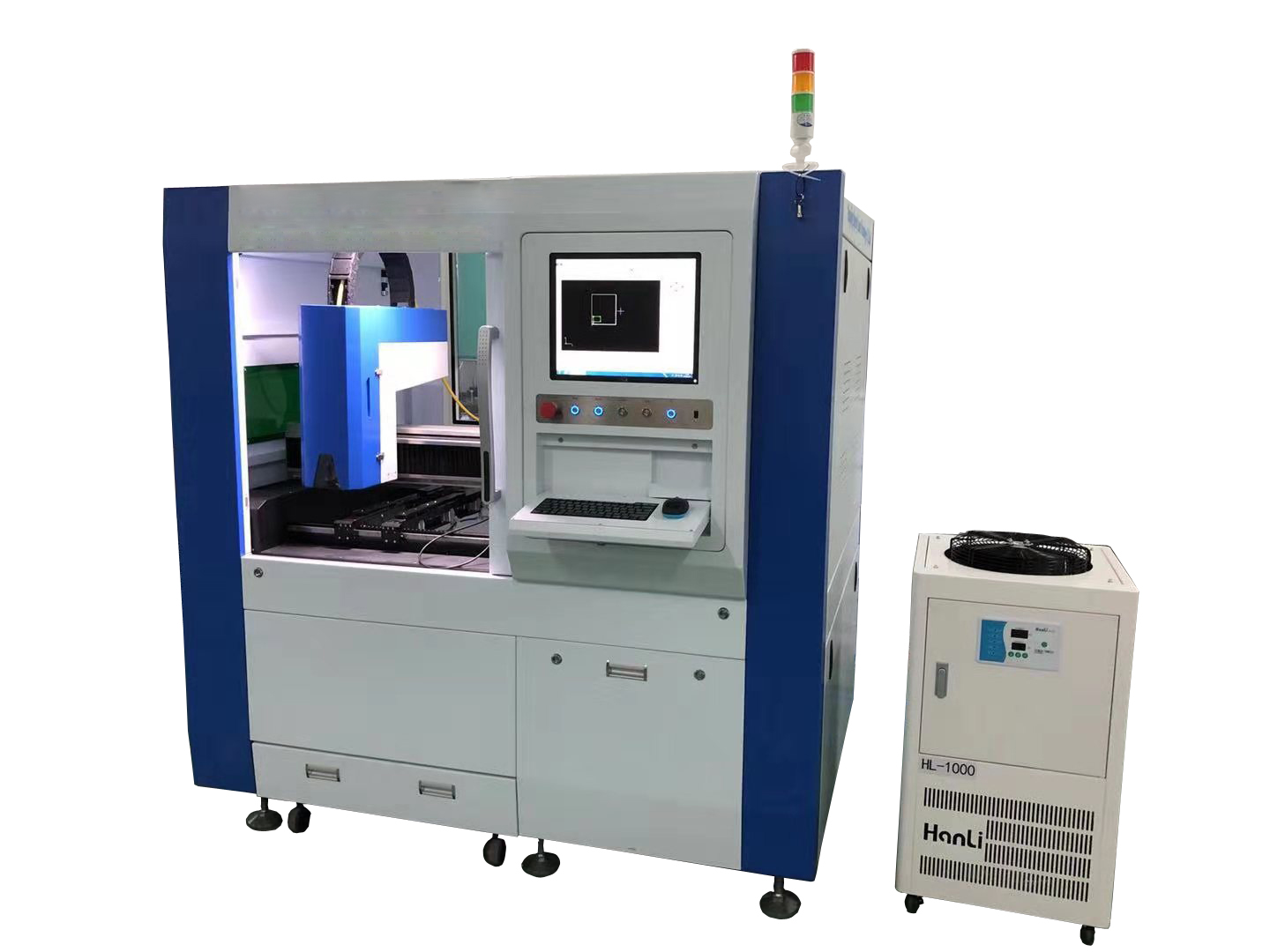

High precision jewelry cutting machine

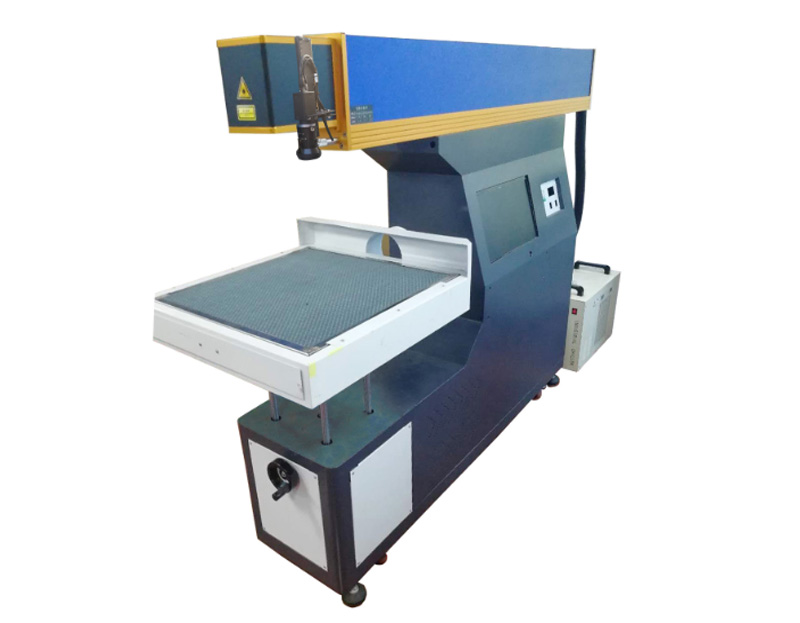

Precise laser cutting machine has wide range applications, such as thin and thick metals and alloys, sapphire, instrumentation, flexible circuit boards, electronic components and precision parts, satisfying many other precision metal cutting needs. Precision laser cutting allows the material to be precise, fine processed and get a finished piece. It also allows for less waste and is less time consuming, resulting in cleaner production and the ability to manufacture in greater quantities.

Video shows:

Machine's features:

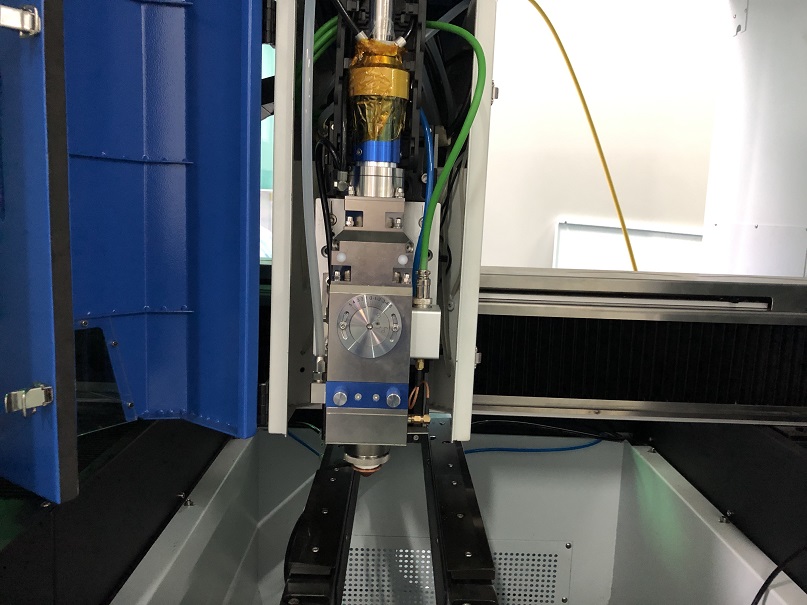

1) Excellent beam quality: Smaller focus diameter and high work efficiency.

2) High cutting speed: Cutting speed is more than 20m/min.

3) Stable running: Adopting the top world Raycus fiber lasers, stable performance,life 100,000 hours.

4) Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption. Fiber line transmission no need reflect lens.

5) Easy operations: Fiber line transmission, no adjustment of optical path;

6) Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.

Parameter

| Model | DS-6060H |

| Laser power | 1KW |

| Laser wavelength | 1070-1080nm |

| Working size | 600x600mm |

| Cutting thickness | 1-3mm brass,aluminum,1-2mm gold,silver |

| Photoelectric conversion efficiency | 25-30% |

| Cutting accuracy | ±0.1mm |

| Max moving speed | 80000mm/min |

| Max loading weight | 600kg |

| Laser light | 100000 hours |

| Cooling mode | Water cooled |

| X axis travel | 600mm |

| Y axis travel | 600mm |

| Z axis travel | 60mm |

| X Y Z axis positioning accuracy | ±0.02mm |

| X Y max position speed | 36m/min |

| X Y axis max acceleration | 0.8G |

| Installed capacity | 8 KVA |

| Rated power voltage | 220V, 50-60Hz |

| Support format | PLT,DXF,DWG,AI |

| Machine weight | 2000kg |

Applicable materials:

1.Stainless steel

2. Galvanized steel

3.Aluminum alloy

4.Titanium alloy

5.Gold

6.Siver

7.Aliminum

8.Brass

9.Copper

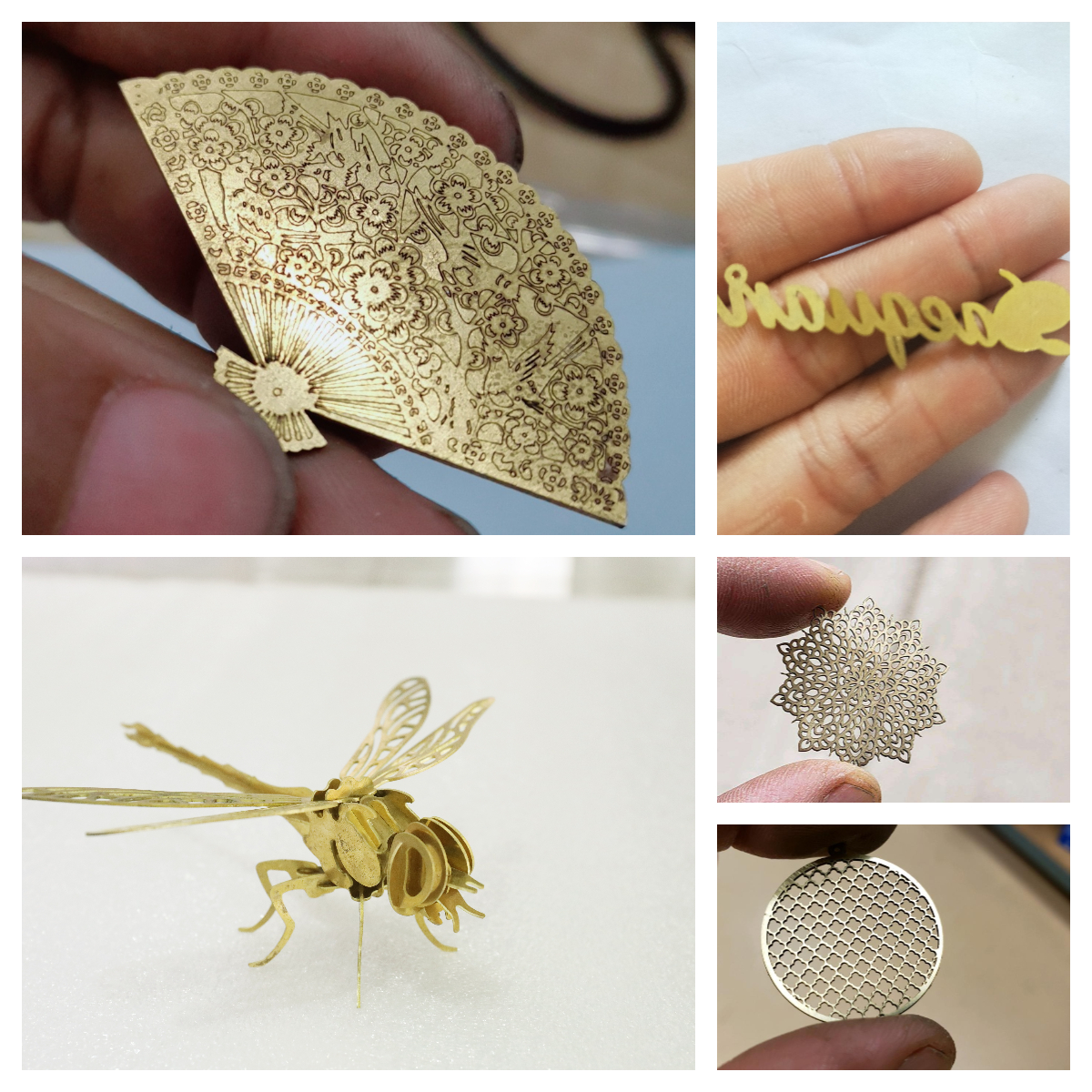

Samples

Why use laser cutting jewelry?

1. Laser cutting machine offers precise cutting, power laser beam vaporize the surface of the material, it can fulfill clean cutting,smooth cutting edge products are very welcomed on the market.

2. Support cutting complicated images, use some software like Adobe Illustrator, CorelDRAW or DraftSight,AutoCAD to design patterns or images.

3. High quality laser cutting machine provides high power and speed. They enable you to cut a variety of materials quickly. Laser cutting machines are manufactured much faster than traditional methods. Fast jewelry manufacturing process, enabling you to produce more pieces of jewelry in less time.

4. Precise cutting and engraving minimizes material waste. It saves you considerable processing costs, especially when dealing with expensive materials. Laser cutting also minimizes the need for additional surface treatment to smooth rough edges. It can save you money and effort spent in the declutter process.

The procedures of using laser cutting jewelry

1. Choose the jewelry type.

First you should choose the jewelry type that you want to cutting, like necklace or ring, bracelet, earrings.

2. Prepare materials and clean the surface

Remember to buy the products accessories like jewerly strap or cleaning tissue, before cutting jewelry to clean the materials ensure perfect cutting.Set up the correct power parameter suit for your products.

3. Maintain a safe cutting environment

Don't put waste on the workbench, in case it will destroy your products or damage the machine, when finish cutting, remember to check the switches are all closed,clean the workbench.

Shipment and package

FAQ

Q1: What are the advantages of laser cutting compared to traditional cutting?

A:Laser cutting is a highly efficient, precise, and versatile process that offers many benefits over traditional cutting methods. Its effectiveness is demonstrated in industries ranging from manufacturing to electronics to jewelry-making.

Q2: How to choose the correct laser cutting machine?

A: When you want to buy a laser cutting machine, you should consider the cost and power, working area and its process speed. What machine is best for cutting yor materials. Contact DOTSLASER professional worker we will give you suggestion for free.

Q3: How do you ensure your machine quality?

A: Dotslaser always invest in ongoing training for employees. Proper training helps to ensure that every team member understands the importance of quality and is equipped with the knowledge and skills needed to maintain it. Employees are understand how to identify potential issues and how to address them promptly.

Q4: How to deal with if your machine goes wrong?

A: Dotslaser machines hvae 1 year warranty, we can offers maintenance free service, we can guide you through video chat how to deal with the problems or can teach you on the site but you need to buy the round ttrip tickets.