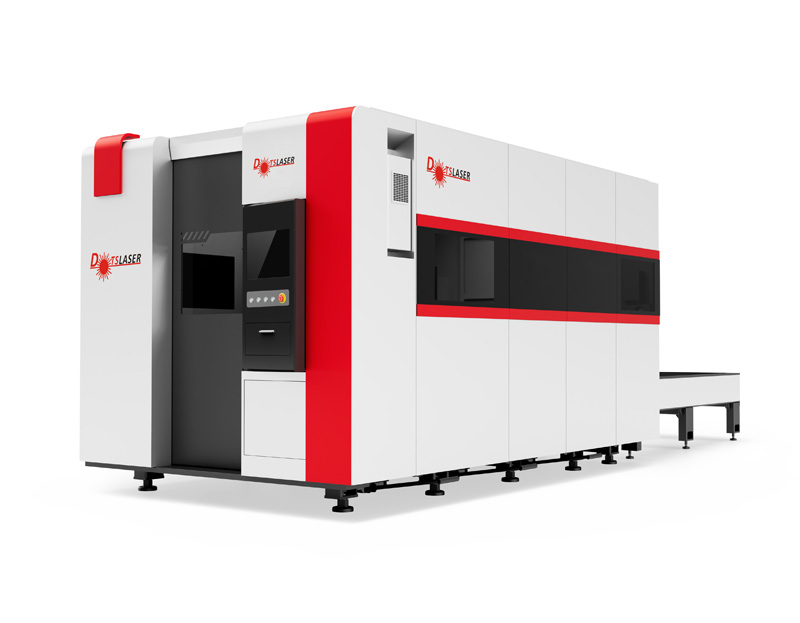

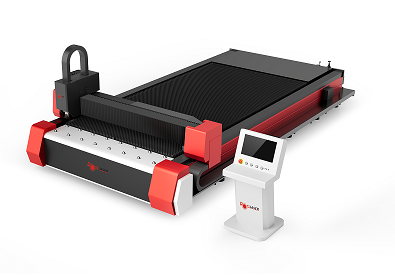

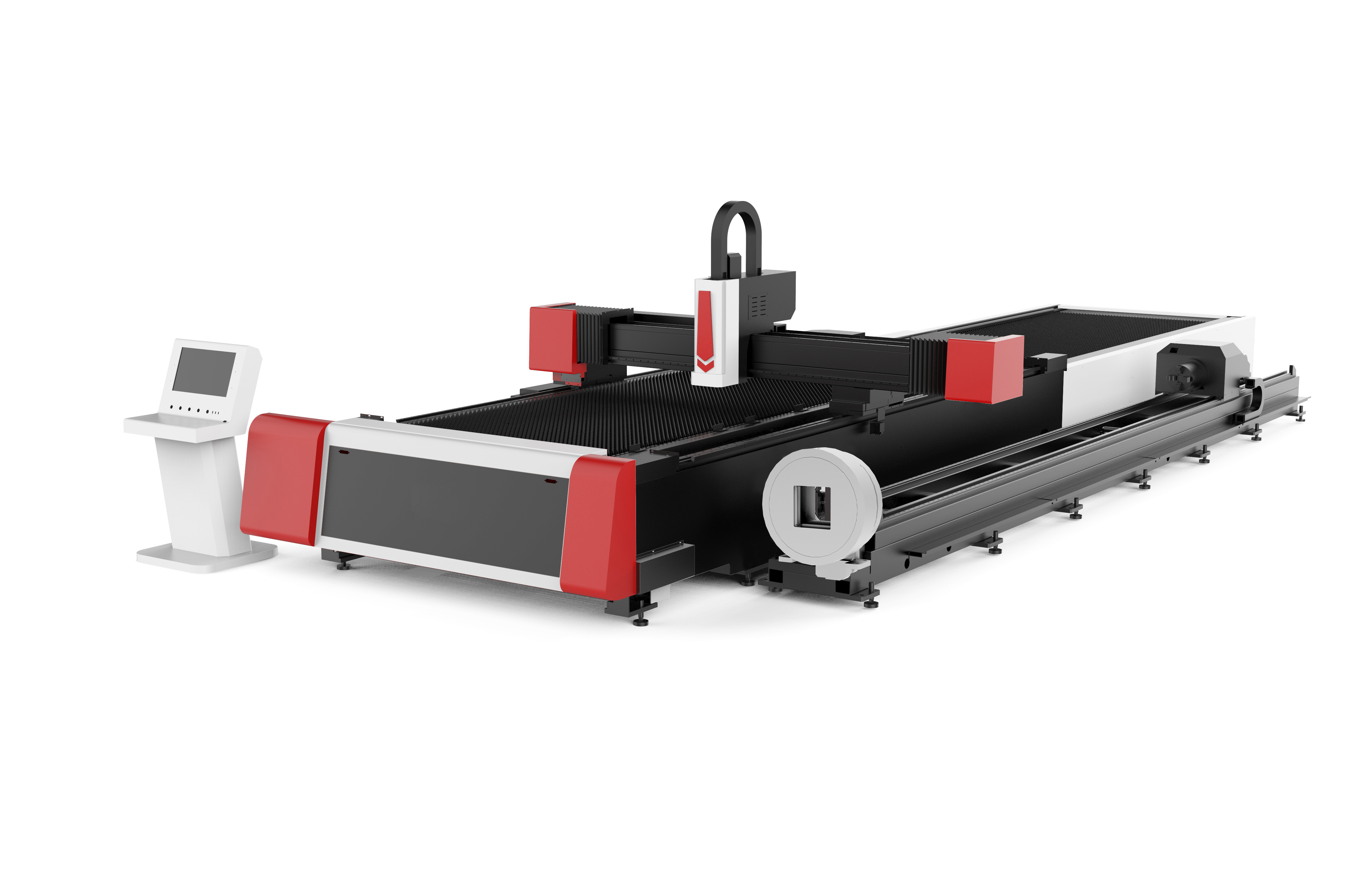

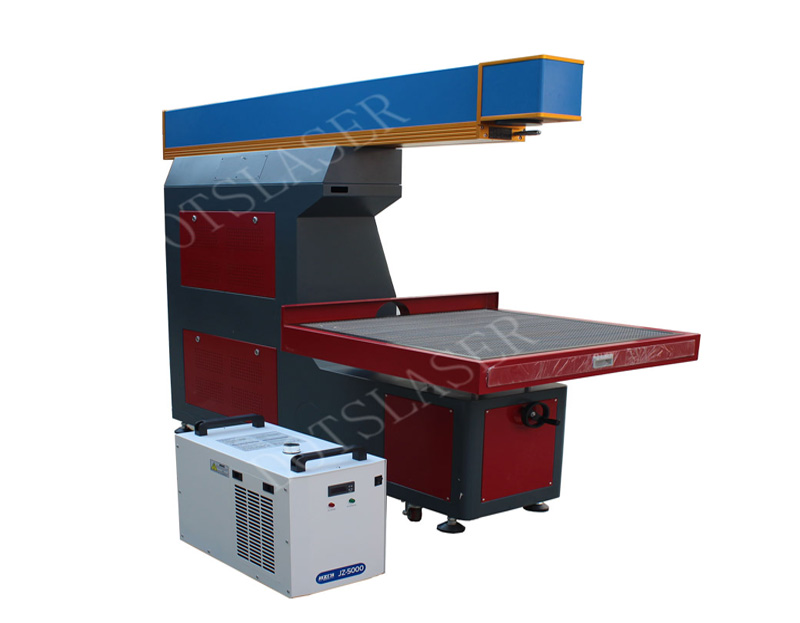

Large format laser cutting metal machine

Large fiber laser cutting uses a simple software control system, which is convenient for workers to operate. The large working table is very suitable for mass production, and high cutting precision attracts many customers and manufacturers. The use of a large format laser cutting machine greatly increases productivity, while the stable laser beam output helps to decrease processing time. Overall, this technology has a positive impact on the manufacturing industry.

Laser cutting process displays:

Principle of laser cutting:

The beam is focused into a small point of light to achieve a high power density at the focal point. At this time, the heat of the beam input (converted by light energy) is far more than the part reflected, conducted and diffused by the material, and the material is quickly heated to the vaporization temperature, evaporating to form holes. As the light beam moves relatively linearly with the material, the holes continuously form a slit of very narrow width.

Machine's features:

1. The advantages of a cutting machine include a narrow cutting seam, minimal deformation, high cutting precision, fast cutting speed, and high cutting efficiency.

2. Laser technology effectively transforms laser light energy into an impressive and concentrated heat energy, resulting in exceptional cutting capabilities such as narrow, precise slits, minimal heat-affected zones, and negligible deformations.

3. The laser beam does not exert any force on the workpiece. It's a non-contact cutting tool, which means that the workpiece experiences no mechanical deformation, and there's no tool deformation or replacement necessary. When cutting materials, there's no need to consider their hardness, meaning that the laser cutting ability remains unaffected by the material's hardness. Overall, laser cutting is a fantastic alternative that offers many benefits.

4. The laser beam has strong controllability, high adaptability and flexibility, and it is easy to realize the automatic production of cutting.

Parameter

Numbers | parameter | |

1 | Laser source power | 6000W |

2 | Processing format (length × wide) | 6000mm×2500mm |

3 | X axis route | 6020mm |

4 | Y axis route | 2520mm |

5 | Z axis route | 260mm |

6 | X/Y axis positioning accuracy | 0.02mm/m |

7 | X/Y axis repeat positioning accuracy | +0.02mm |

8 | Maximum speed | 110m/min |

9 | Maximum acceleration | 1.5G |

10 | Worktable maximum load | 2000kg |

11 | Phase | 3 |

12 | Rated supply voltage | 380V |

13 | Frequency: | 50Hz |

14 | Total power supply protection class | IP54 |

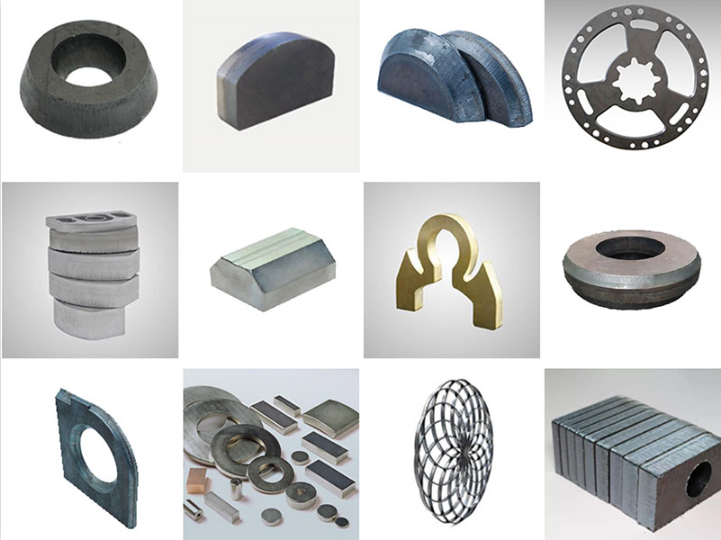

Samples

Application of fiber laser cutting metal machine:

Large format fiber laser sheet metal cutting table is one powerful fiber laser cutting machine can cut through stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and so on. Ultra-Large format fiber laser sheet metal cutting table is used in various industries such as machinery components, electrics, electrical cabinets, kitchenware, elevator panel, hardware tools, with the advantages of high efficiency, safety and high accuracy, which can improve work efficiency and product quality.

Shipment and package

Certificate