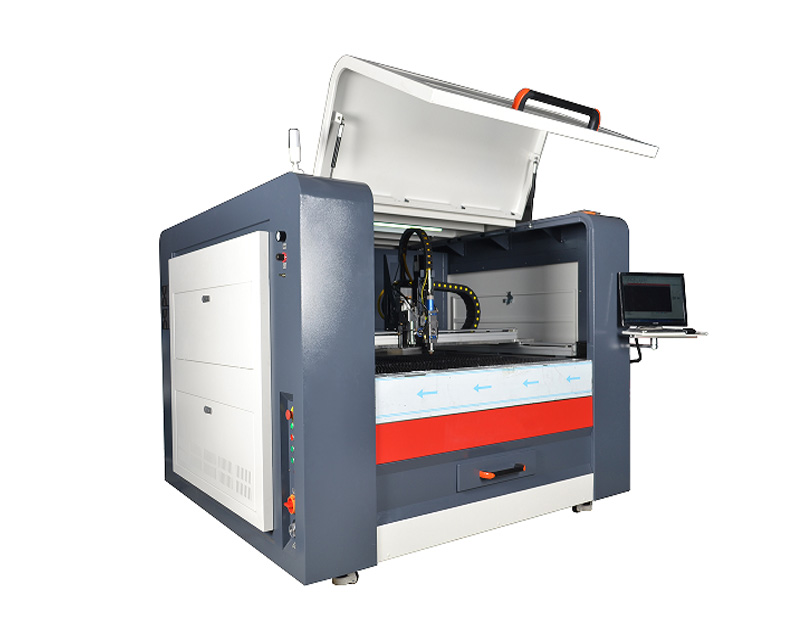

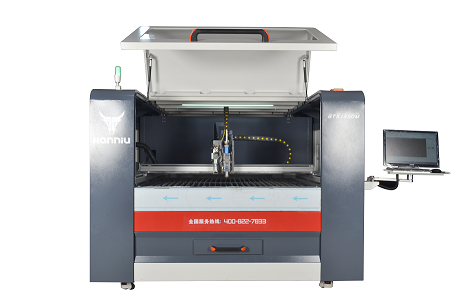

Fiber laser cutting metal machine

Fiber laser cutting machine can cut many materials with fast speed and high precision, such as metal, aluminum,wood, copper,arcylice,glass, plastics and polymers,titanium, stainless steel. Compact whole machine, 24 hours continuous working, increase productivity grreatly, less consumables, machine lifetime can reach 100000 hours. If you want to purchase a cutting machine this serie is the best choice!

Video shows:

Machine's features:

1.Cutting flexibility

Laser cutting does not require an exchange of tools for each separate cut. The same setup is suitable for cutting a lot of different shapes within the same material thickness. Also, intricate cuts do not pose any problems.

2. Precision

Cutting accuracy is the most obvious advantage in the laser cutting machine, no matter what angles and thickness, adjusting properly machine's parameter can reach the ideal effect, Z axis structure with unique design, high speed processing, precise control, specially suitable for cutting delicate small holes.

3.Versatile

Laser cutting machine is suitable for cutting a lot of materials, there are including different metals, acrylic, MDF, wood, paper, etc. One machine can be configured to perform different jobs. Of course, the ability to cut some of these materials depends on the power of your machine.

Parameter

Maximum processing range | 900x1300mm |

X-axis travel | 920mm |

Y-axis travel | 1320mm |

Z-axis travel | 80mm |

X/Y axis positioning accuracy | ±0.03mm |

X/Y axis repeat positioning accuracy | ±0.02mm |

X/Y maximum moving speed | 40m/min |

X/Y maximum moving speed acceleration | 0.5G |

Working exchange platform | No |

Working platform load | 250KG |

Enclosed laser protection | Yes

|

Lubrication type | Automatic oiling |

Power available | 1000-2000w |

Total power with 1000w raycus | 12KW(29A) |

Total power with 1000w ipg | 12KW(54A) |

Total power with 1500W | 14KW |

Total power with 2000W | 16kw |

Machine dimension | 2100x2700x1650mm³ |

Total weight | 1500KG |

Machine's components

1. Laser source

Higher electro optic-convension efficiency, superior reliability & modularity, simple operation and low down time, anti high reflection function, maintenance free, fiber laser cutting with high cutting quality, smooth cutting edge, excellent laser beam ensures flawless cutting.

2. Smart control board

Integrated circuit, support non-contact process, the galvanometer control board has the characteristics of high precision, high speed and high stability. It can precisely control the rotation Angle and speed of the galvanometer through digital signals, so as to achieve accurate control of the laser beam. In addition, the galvanometer control board also has the advantages of easy integration and easy control, and can be easily integrated and connected with other devices or systems.

3. Water chiller

Laser cutting machine chiller offers stable working temperature for the whole machine, increase processing efficiency and machine's lifetime, in the process of laser cutting, the working temperature of the laser directly affects its output power and beam quality. Too high or too low temperature will lead to laser performance degradation, or even broken. The chiller ensures that the laser always works at the best temperature through a stable cooling water temperature, ensuring cutting quality and processing efficiency.

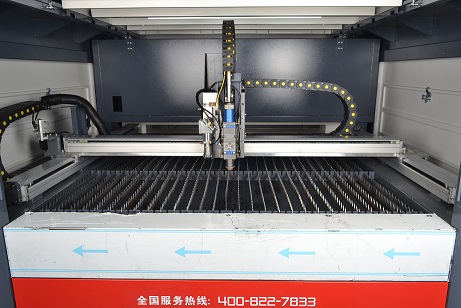

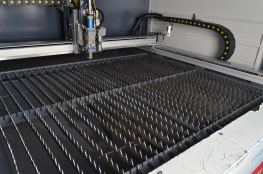

4. Large format workbench

Laser cutting machine workbench is fulfill X,Y,Z axis parts of mechanical movement, it is used to place the workpiece to be cut, and can move correctly and accurately according to the control program, usually driven by a servo motor.

Laser cutting technology in various industries:

1. Automotive Industry

In the automotive industries, laser cutting technology especially for cutting intricate components and customization. such as engine components shapes with high accuracy.

2. Aerospace industry

When use laser cutting technology in aerospace industry, the need for lightweight, high-strength materials in this sector cannot be overstated. Precision is the hallmark of aerospace components, and laser cutting, with its high precision and ability to handle a wide range of materials, is perfectly suited for this task.

3. Construction Industry

Laser-cut steel panels used in innovative building designs and custom architectural elements that showcase intricate patterns and shapes, laser cutting machine plays an important role in construction industry.

4. Medical Device Industry

Produced surgical tools with intricate designs, surgical tools need more precise cutting, laser cutting machine is equipped with smart control board and power laser source, where every millimeter can impact a patient’s outcome, but when you use laser cuttting, it can cut the tools shapes precisely and quickly.

5. Electronic industry

Laser cutting machine also can be use in electronic industry, intricated design with PCB cards and silicon wafers, a crucial step in semiconductor manufacturing can be cut by the laser machine.

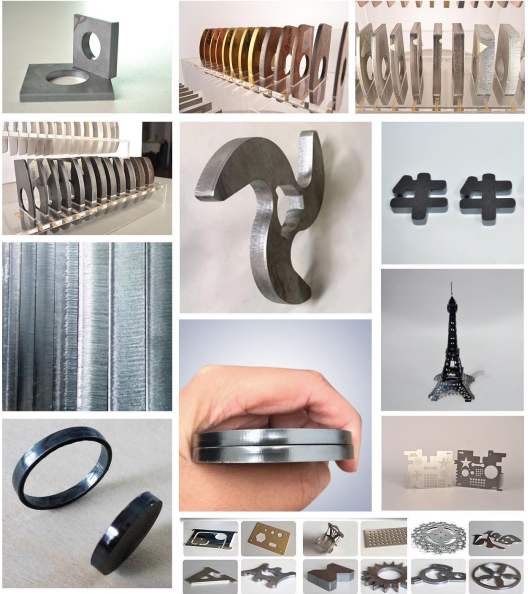

Cutting machine's samples

Wooden case package

Certificate

Unpacking caution

Every cutting machine has been rigorously tested at the factory, only qualified product for shipment. When you receive the freight, please check as follows. If you have any questions, please contact the

agent or staff at DOTSLASER.

● Whether there is damage or deformation during transport.

● Confirm that all of the items on the packing list are correct.

● Confirm that the model of the product matches the nameplate(Operating voltage and KVA

number).

● Make sure that all clamps are tight and that there are no foreign objects in the device.

● Confirm the operation buttons, switches are normal.