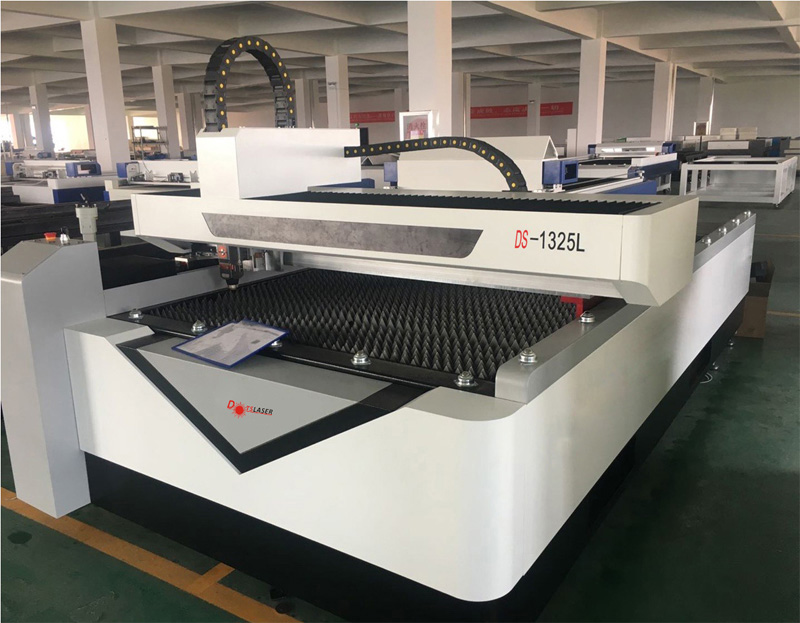

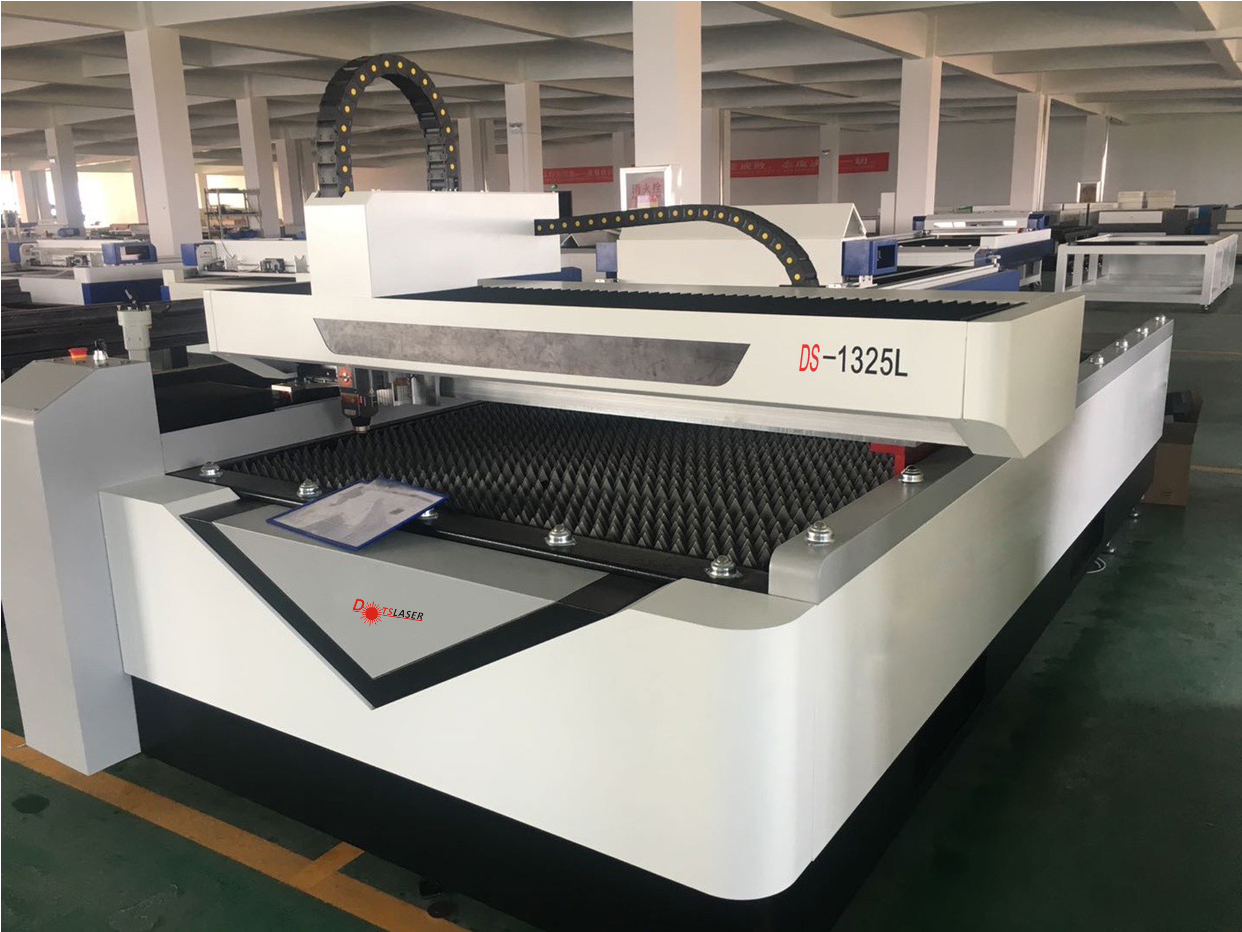

Large fiber laser precise cutter

Large format fiber laser cutting machine is a powerful cutter, it has wide range of applications. Such as stainlesss steel, titanium , plastics, copper, aluminum, brass, stone, glass and so on. Laser cutting machine has unique characters with high precision, high efficiency and safety depends on its power laser source and smart servo motor. Different cutting angles also can create smooth and flawless cutting edge.

Video shows:

Machine's features

1. Intelligent control system

Automatic edge patrol, full tracking compensation, fulfill flying cutting, avoid waste of raw materials, ensures cutting accuracy and quality.

2. Large format cutting workbench

Large format cutting workbench suitable for mass production, increase productivity greatly.

3.High-tech cutting head

Designed for high power and 24/7 operation for exceptional cutting performance.

4. Precise cutting

Laser cutting machine one of the most obvious advantage is its cutting precision, power laser source and smart servo motor well control cutting precision.

Parameter

Technical parameters | |

Cooling mode | Air |

Max dischage pressure | 1.3Mpa |

Motor power | 11kw |

Power supply | 380V 50HZ |

Exhaust oil content | ≦3PPm |

The amount of dust | ≤3μm |

Machine noise | 66±2dB(A) |

Volume of storage tank | 1000L |

Applicable materials:

1. Metal plates

2. Mainly used in cutting stainless steel

3. Carbon steel

4. Galvanized sheet

5. Electrolytic plate

6. Brass, aluminum

7. Various alloy plate

8. Rare metal and other metal materials

What's the procedures of using laser cutting machine?

Step 1: Prepare the machine

Before using the laser cutting machine, it's important to make sure it's properly setup. Check that the machine is clean and without debris. Ensure that the laser is properly aligned. Make sure that the workpiece is securely in place on the machine.

Step 2: Set the parameters

The next step is to set the parameters for the cutting job. This includes selecting the appropriate power level for the laser and determining the speed at which the machine will cut. The parameters will vary depending on the material being cut, as different materials require different power levels and cutting speeds.

Step 3: Start the machine

Once the parameters are set, it's time to start the machine. The laser cutting process is automated, so the machine will perform the cutting automatically once it's started. It's important to monitor the cutting process to ensure that everything is going smoothly.

Step 4: Remove the cut workpiece

Once the cutting is complete, the workpiece can be removed from the machine. It's important to handle the workpiece with care, as the edges may be sharp. Depending on the material, it may also be hot when you want to touch.

Step 5: Clean up

Finally, it's important to clean up the machine after use. This includes removing any debris from the machine and ensuring that all parts are in good working order. It's also important to follow any maintenance. procedures recommended by the manufacturer to prolong the life of the machine.

Samples

Shipment and package

Certificate

Attentions:

1. Protective Gear:

Laser cutting generates intense heat and light, so it is essential to use protective gear such as safety glasses, gloves, and face shields to avoid any accidents.

2. Proper Ventilation:

Dotslaser cutting machine all equipped with ventilation, so any gases or fumes are filtered out. These fumes are harmful to human health and should not be inhaled, protect human body.

3. Proper Maintenance:

It's important to keep the laser cutting machine well maintained and in good condition. This involves regularly cleaning and replacing parts that are worn out or damaged. This will ensure that the machine is in proper working condition and operates efficiently.

4. Master the Machine:

It's important to master the working of the laser cutting machine to ensure that you are using it correctly. Any misuse or mishandling of the machine can result in accidents and injuries.

5. Follow Safety Guidelines:

When using the laser cutting machine, always follow the safety guidelines provided by the manufacturer or employer. These guidelines will help you understand the correct operation, maintenance, and safety procedures, ensuring a safe and productive working environment.