Hardware Kitchenware Sanitary Ware Stainless Steel Door Automotive Handheld Laser Welding Machine

Applications:Cabinets, kitchens, stairs, elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel furniture, hardware devices, triangular valves, stainless steel sinks, water pipe fittings, stainless steel round pipe tee pipe bends, floor drains, door handles and locks wait.

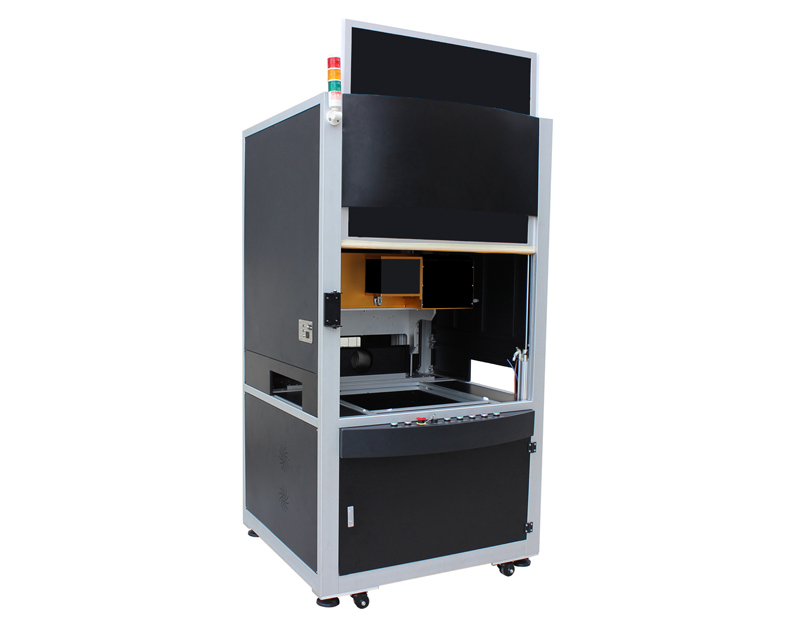

Handheld Laser Welding Machine

1.Features and advantages

Small design

Handheld and flexible

High efficiency and perfect effect

Fast welding speed. 2~10times faster than traditional welding.

Easy to operate and use, no need getting professional welding certificate.

Perfect welding seam, no need secondary polishment.

Less consumable parts.

Long life time: normally it can work for 8~10years,even longer.

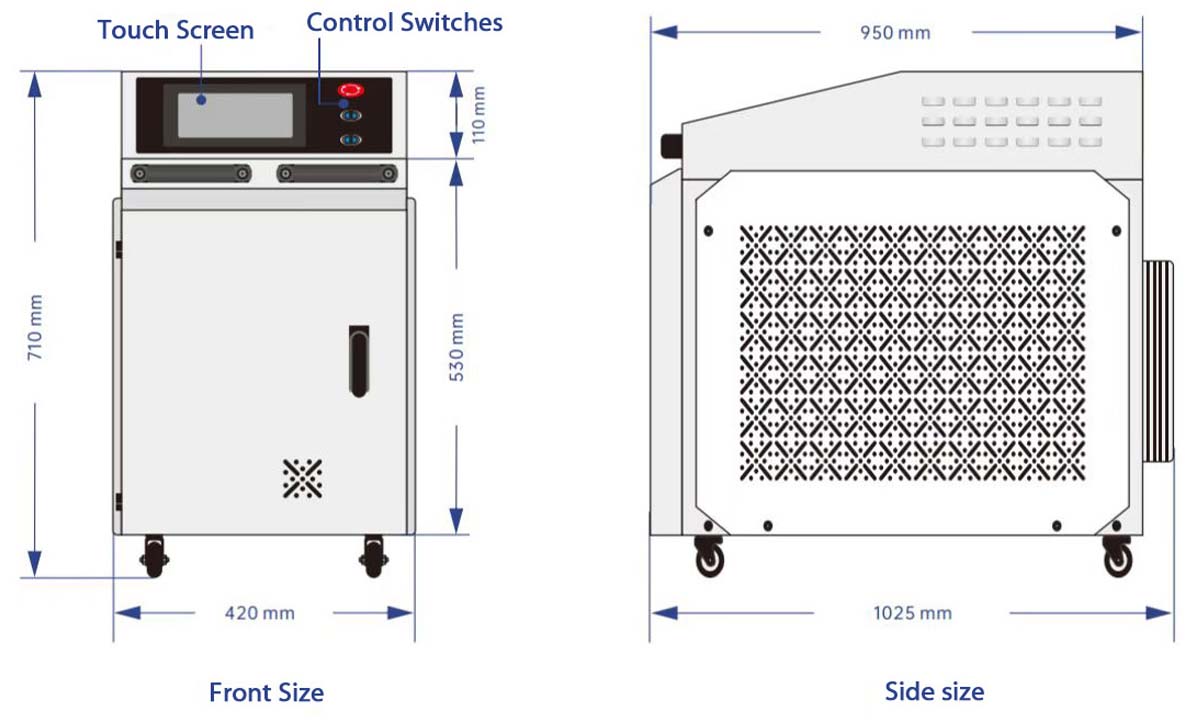

2.Dimensions.

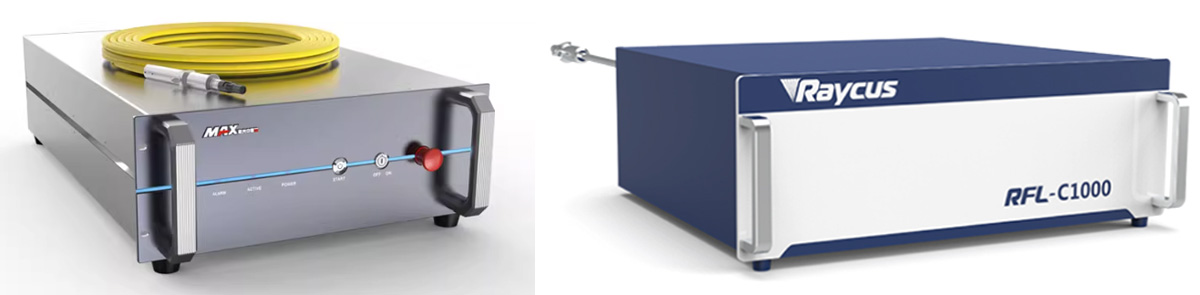

3.Main configurations.

a.Laser source

Top brand laser source: MAX, Raycus,JPT,BWT, etc, laser source is one of the core components for a handheld laser welding machine, its quality and features has an important role, so select a suitable laser source is first step.

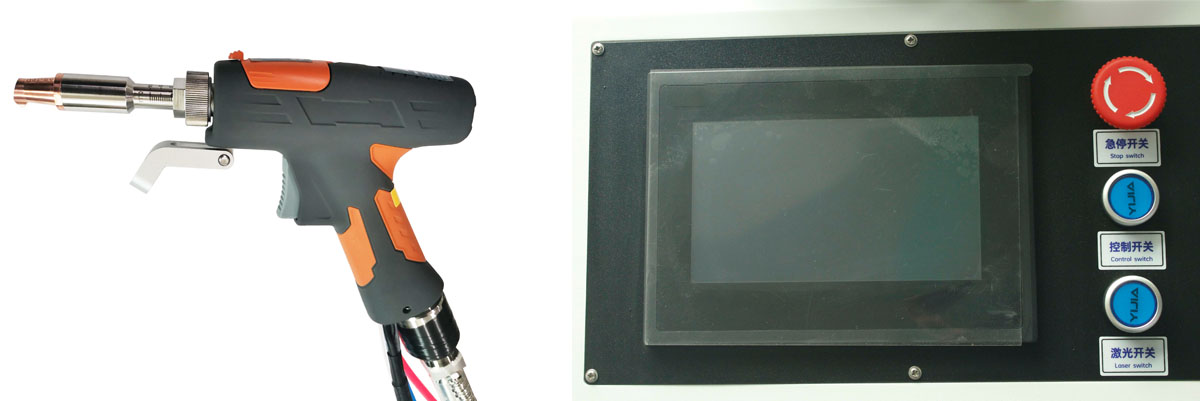

b.Welding gun and controller

We use the most popular and high reputation welding gun and personized control system,which can control the laser beam output perfectly to get a best welding result and higher welding efficiency. What`s more, its failure rate is quite low compared with others.

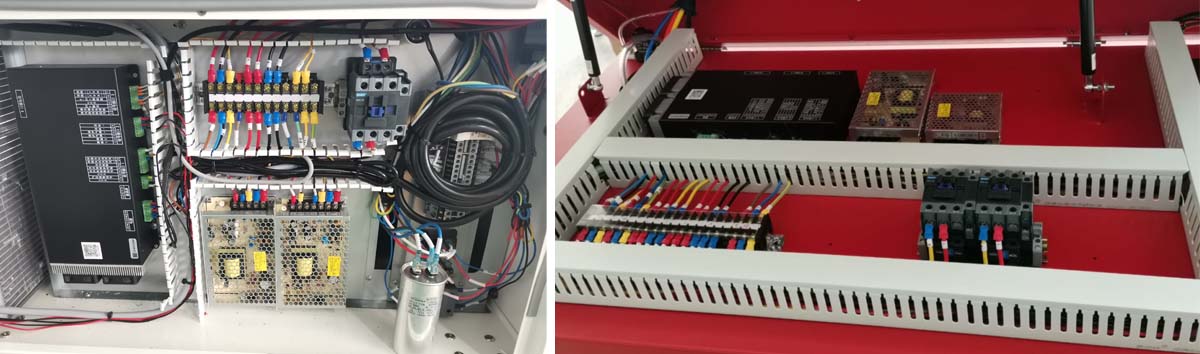

c.High Assembly Level

The level of assembly often determines the product quality of the welding machine. The products manufactured by an experienced company that pays attention to product details can greatly reduce the product failure rate and improve the service life of the product, which can reduce many unnecessary troubles during work.

4.Parameters.

| Model | DS-LW1000/DS-LW1500/DS-LW2000/DS-LW3000 |

| Laser power | 1000W/1500W/2000W/3000W |

| Wavelength | 1080±5nm |

| Operating mode | Continuous/Modulation |

| Power adjusted range | 10~100% |

| Fiber core diameter | 50(25,100,200 optional) |

| Fiber cable length | 10meter |

| Welding speed | 0~120mm/s |

| Welding thickness | <3.5mm(depend on the material) |

| Cooling method | Water cooling |

| Working environment | 10~40℃,humidity 10~85%,no condensation |

| Rated power | 6KW |

| Power supply | 380±10% VAC,50/60Hz |

| Dimensions | 1025×420×710mm(1000W~2000W)/1150×630×1080mm(3000W) |

| Total weight | Approximately 180kg(1000W~2000W)/250kg(3000W) |

5.Samples

6.Why choose handheld laser welding machine?

With the development of laser technology, laser welding technology has become mature, and laser welding has a high level of technology. Laser technology is another major invention at present. The appearance of laser welding machine has given a qualitative leap to the current welding technology, allowing metal and non-metal materials of different materials to be easily connected, allowing us to get rid of some traditional processing troubled.

Advantages of handheld laser welding.

Hand-held laser welding is fast, 2-10 times faster than traditional welding, and one machine can save at least two welders a year. The weld seam after welding is smooth and beautiful, reducing the subsequent grinding process, saving time and cost. The laser welding workpiece has no deformation, no welding scars, and the welding is firm. Laser welding consumes less consumables and has a long service life.

New process of filler wire laser welding technology

Laser wire filler welding is a method of using filler metal of the same or similar material as the base metal to melt the base metal and solder and then condense to form a weld. Laser welding generally does not fill the welding wire, but it has high requirements for the assembly gap of the weldment, which is sometimes difficult to guarantee in actual production, which limits its application range. The use of wire-filled laser welding can greatly reduce the requirements for assembly clearance. For example, for an aluminum alloy plate with a plate thickness of 2mm, if no filler wire is used, the gap between the plates must be zero to obtain a good shape. If a φ1.6mm welding wire is used as the filler metal, the weld can be guaranteed even if the gap is increased to 1.0mm. good shape. In addition, the filler wire can also adjust the chemical composition or carry out multi-layer welding of thick plates.

Development Status of Laser Welding

In the field of metal welding, aluminum alloy welding accounts for a large proportion, because aluminum alloy has high specific strength, high fatigue strength, good fracture toughness and low crack growth rate, and also has excellent forming processability and good resistance Corrosive, has been widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding and chemical industry. The wide application of aluminum alloy has promoted the development of aluminum alloy welding technology, and the development of welding technology has promoted the research of laser welding technology, and the development of welding technology has expanded the application field of aluminum alloy.

7.Video