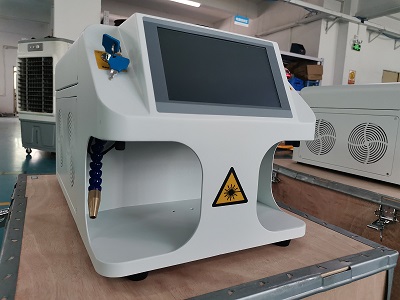

Jewelry laser welding machine

Jewelry laser welding machine is especially for welding delicate jewelry, including bracelet, ring, necklace, earring or other stainlesss steel ornaments. with its precise welding, its perfect welding effect on jewelry is popular in jewelry market. During the welding process, the surface of the jewelry is heated, and the heat is gradually transmitted to the inside of the material and diffused. By controlling the width, energy, peak power, repetition frequency and other parameters of the laser, the jewelry is melted and a specific melting pool is formed. Jewelry laser welders produce precise, clean welds with minimal thermal deformation.

Video shows:

Machine's features:

1. Less heat-affected zone

Laer welding machine has equipped with a cooling system, it can adjust the welding temperature of whole machine, it won't cause deformation of the products due to overheat situation, it has a precise control temperature system.

2. Advanced light shielding system

Jewelry laser welding machine equipped with automatic shielding system, protect woker's eyes don't suffer from laser radiation.

3. Deep and firm welding

Adjusting proper parameter of the machine according to welding materials, so that can achieve the ideal welding effect, such as energy, pulse width, frequency and light spot.

Parameter

Model | DS-100 |

Power | 100W |

Wavelength | 1064nm |

Welding depth | 0.1-2.5mm |

Welding spot diameter | 0.1-3.0mm |

Pulse width | 0.1-20ms |

Frequency | 1-30Hz |

Power requirement | 220/50hz |

Cooling method | Water cooling |

Observing system | CCD/ microscope |

Size | 650 *360 * 560mm |

Net weight | 26kg |

Gross weight | 40kg |

Application:

This machine aids in easily welding precise meatls like platinum, titanium, gold, silver and palladium, also, ot can repaire jewelry flaws, such as repairing casting defects, porosity filling, prong, micro pave,without removing the stone.

Main components:

What're the benefits of laser welding on jewelry?

1. Clean and precise weld: Laser welding does not require any additional finishing. Jewelry blemish can be very noticeable. With laser welding, there are no messy flux or solder residues to clean up, leaving a perfectly seamless finish.

2. Higher techniques: Laser welding can be used to join dissimilar metals, as well as thin and delicate pieces of jewelry without damaging them. This means that jewelers have more flexibility in terms of the materials they use and the designs they can create.

3. Welding quick process: Laser welding is much faster than tradition weldingt, can produce multiple pieces in a shorter amount of time. It's suitable for small scale produces who need to produce large quantities of items quickly.

4. Safe guarantee: Laser welding does not use open flames or chemicals, it is an environmentally friendly and safe method of production. The lack of open flames and toxic gases also means a safer work environment for the jeweler.

Samples

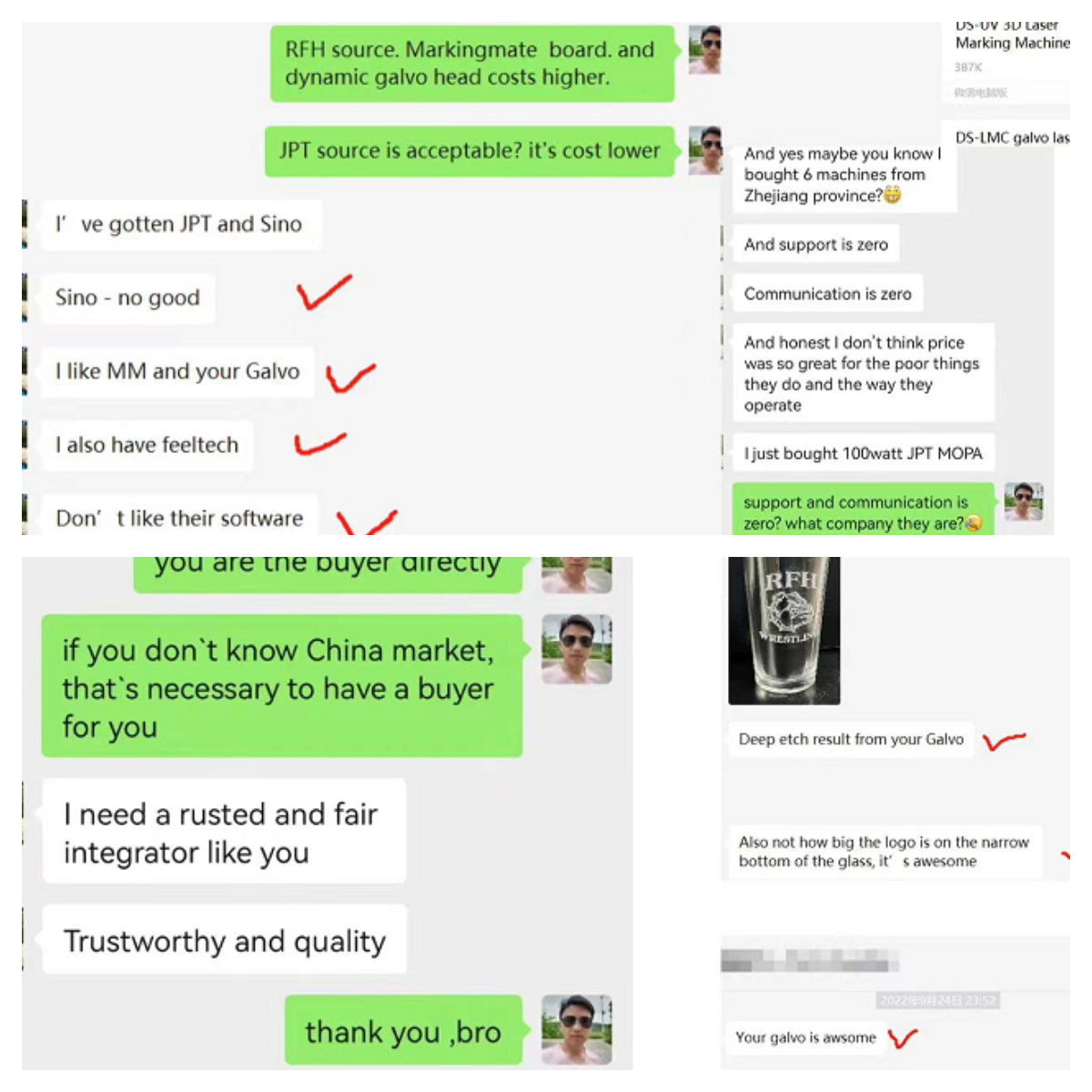

Customer's feedback

Shipment

Certificate