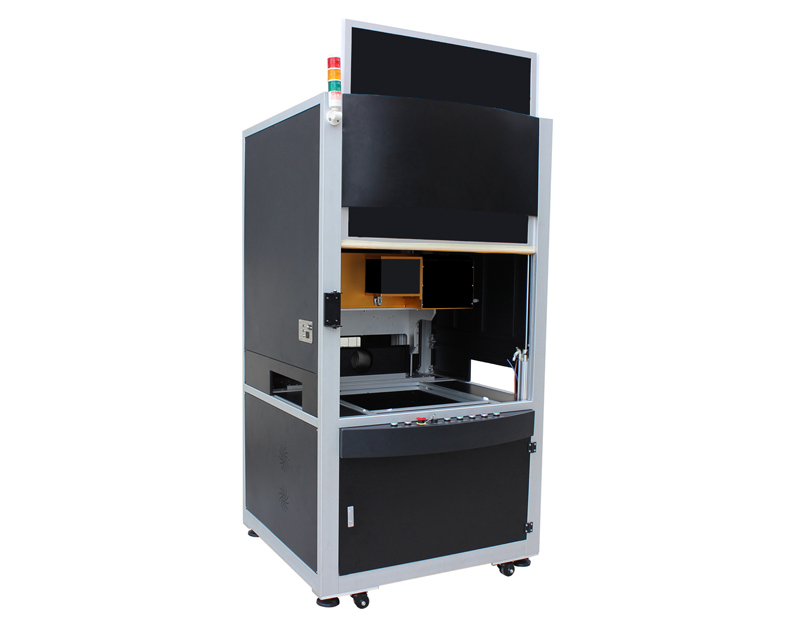

Laser welding for kitchenware

Large laser welding machine is suitable for home kitchenware welding and repair, beautiful welding seam and welding surface has attarct many customers and industries, one welding machine has versatile usages, it can weld various materials, such as metal, steel,satinless steel, titanium and carbon steel. Non-contact processing won't damage the materials, keep materials integrity, falt and smooth welding seam offers good touching experience.

Video shows:

What're the advantages of laser welding in kitchenware?

1. Perfect welding seam

Laser welding with less deformation, small heat-affected zone, high aspect ratio. The welding seam is beautiful, smooth, without air holes, no need to handle or simple treatment after welding, small spotlight, no pollution.

2. Precise welding

High-precision positioning, the handle laser welding machine can be used for small open parts and precise welding. Compared with traditional welding machine, overheat welding may cause materials deformation, more and more companies use laser welding machine for processing and manufacturing.

3. High quality welding

When the laser welding machine is used for processing, the welding surface is very flat, and the problem of excessive surface dissolution area during traditional welding processing does not occur, so the welding quality of the laser welding machine is very good.

4. Fast welding speed

The laser welding machine equipped with a powerful servo motor and laser source, so the welding speed is fast and welding effect is perfect. Fast welding speed saves a lot of processing time and labor cost.

Main accessories:

1. Scanning head

2. Laser source

3. Large workbench

Parameter

Model | DS1500/DS200/DS3000 |

Laser power | 1500W/2000W/3000W |

Pulse width | 0.1-20ms |

Operating voltage | 220V/380V |

Fiber length | 10M/12M/15M, Maximum 20m |

Maximum Oscillation Speed | 20000mm/s |

Frequency | 0-100HZ |

Wavelength | 1064nm |

Solder joint size | 0.2-3.0mm |

Cooling method | Water cooling |

Laser model | CW |

Observation system | Microscope (rotatable 360 degree) or display |

Positioning | Red indicator |

Why laser weldinig is popular in the market?

▲1. Compared with traditional welding, the traditional welding technology always with high temperture characteristics in welding process, traditional welding can't perform well time control. However, lase welding machine effect is popular in the market, customers are love it, more and more companies use laser welding machines for processing and manufacturing.

▲2. When the laser welding machine is used for processing, the welding surface is very flat, and the problem of excessive surface dissolution area during traditional welding processing does not occur, so the welding quality of the laser welding machine is very good. Because the traditional welding is heated successively when the welding material is melted, the welding surface appears very rough. However, using a laser welding machine for welding and heating by a laser beam, the welding effect is ideal.

▲3. Kitchenware laser welding machine can help to save much electric energy compared with arc welding, 30% processing cost can save, it can weld different metals and steels, and can easily complete mechanization and automation. Fast speed, small deformation, small heat-affected zone, high aspect ratio. The welding seam is beautiful, smooth, without air holes, no need to handle or simple treatment after welding, small spotlight, no pollution, high-precision positioning, the handheld laser welding machine can be used for small open parts and precise welding.

▲4. Due to laser welding machine uses low heat input during laser welding of kitchenware, less deformation to be happened, and the welding surface is very small, beautiful welding seam. Automatic laser welding machines can greatly reduce or eliminate huge polishing and leveling, resulting in a low labor cost of the process.

Samples

Shipment