laser welding for steel

laser welding for steel, power is optional,normally 1000W,1500W,2000W, hand held type, the welding material can be steel, stainless steel,carbon steel,aluminum,brass,copper,iron,alloy, and so on

DS-LWseries laser welding for steel

laser welding for steel is a leading technolgy for welding metal material with a better result. Compared with traditional electric welding, laser welding result is perfect, no abvious welding scar,blacken,yellowish,burned result.

Production Description

DS-LW series handheld laser welding machine is a new generation of laser welding products. The laser chooses Raycus high-quality laser source. The whole machine adopts integrated design, beautiful appearance and stable performance, easy to install and simple to operate , High safety. The characteristics include fast welding speed, high effificiency, good welding effect, less welding consumables, long life and environmental protection. It can be widely used in kitchen appliances, door and window guardrails, staircase elevators, stainless steel furniture, metal sheet metal, and advertising Welding in industries such as brand, craft gifts, auto repair, auto manufacturing, rail transit and aerospace.

DS-LW series hand-held laser welding machine standard wire distribution machine reduces the requirements of parts for gaps and further improves the welding quality. It can also be used in conjunction with a collaborative robot to fifix the welding torch on the collaborative robot to reduce the labor intensity of the operator and improve the welding quality of the weld.

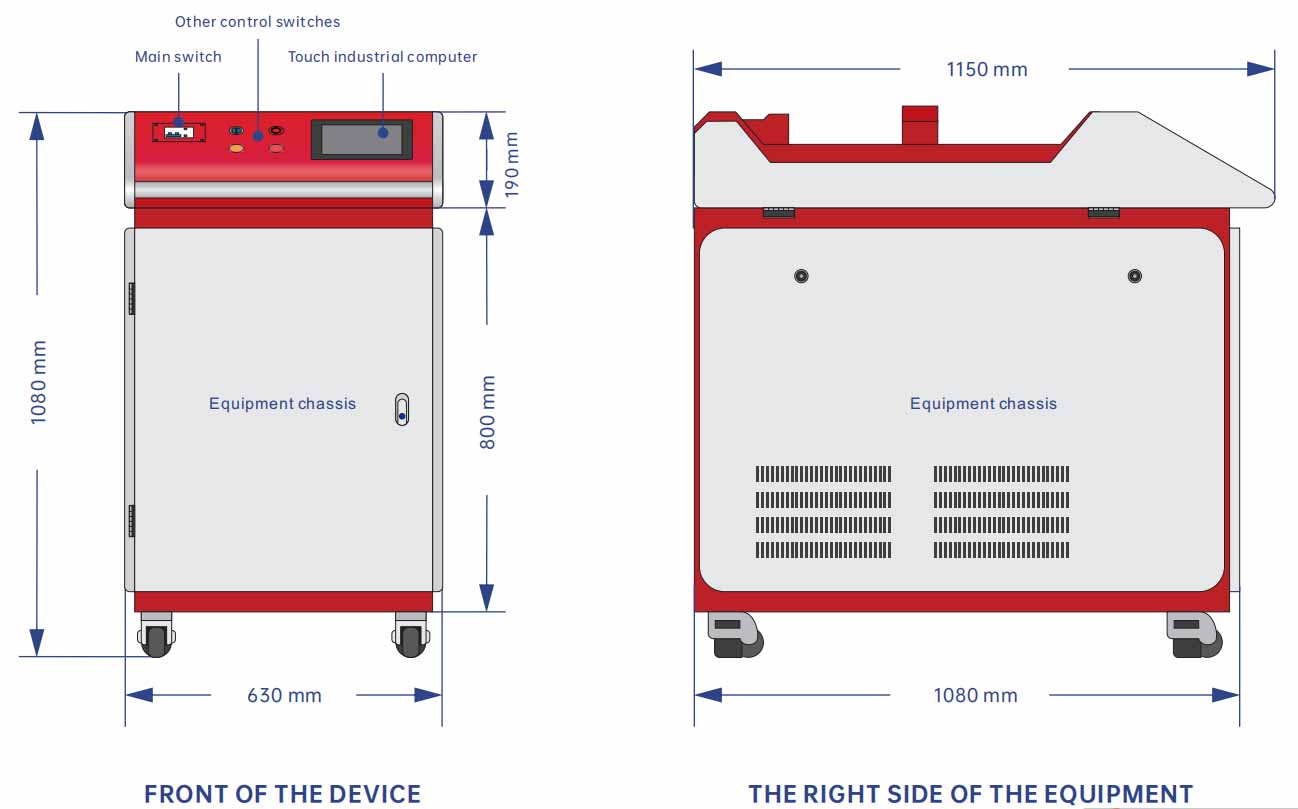

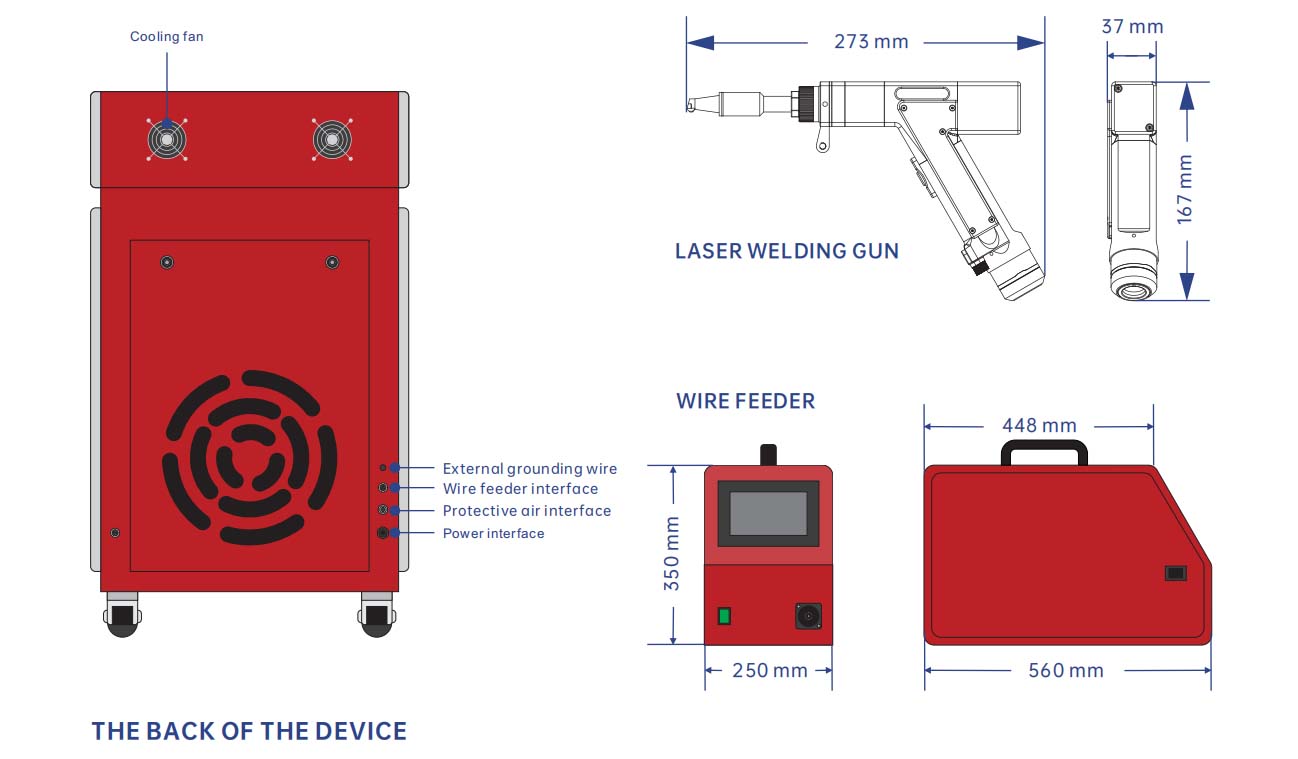

Product size

Product Features

The internal design is dexterous, and the good interactive control system expands the tolerance range of the processed parts and the width of the weld seam, solves the disadvantage of small light spot, and makes the weld seam better; The internal design is dexterous, and the good interactive control system expands the tolerance range of the processed parts and the width of the weld seam, solves the disadvantage of small light spot, and makes the weld seam better;

The shape is light, the design method of body engineering is adopted, and the grip is comfortable; it is easy to control with one hand, and the operation is simple and easy to use;

With multiple safety alarms, the light will be automatically locked after the workpiece is removed, and the safety is high;

Beautiful welding seam, fast speed, no consumables, no welding marks, no discoloration, no need for later polishing;

A variety of angle nozzles can be confifigured to meet the welding needs of different products.

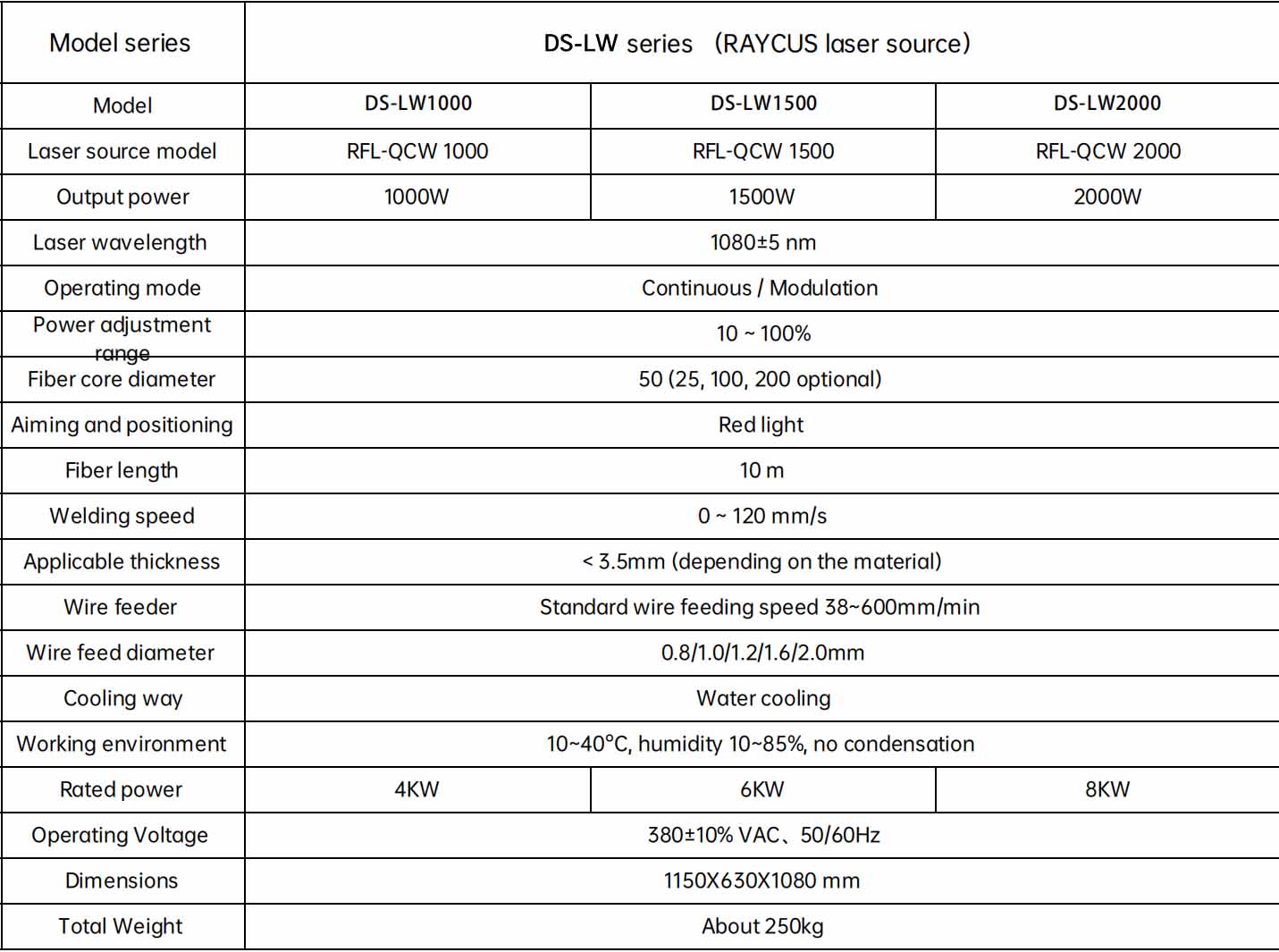

P R O D U CT PARAMETE R

SAMPLE PICT U R ES

STA N DAR D LAY O U T

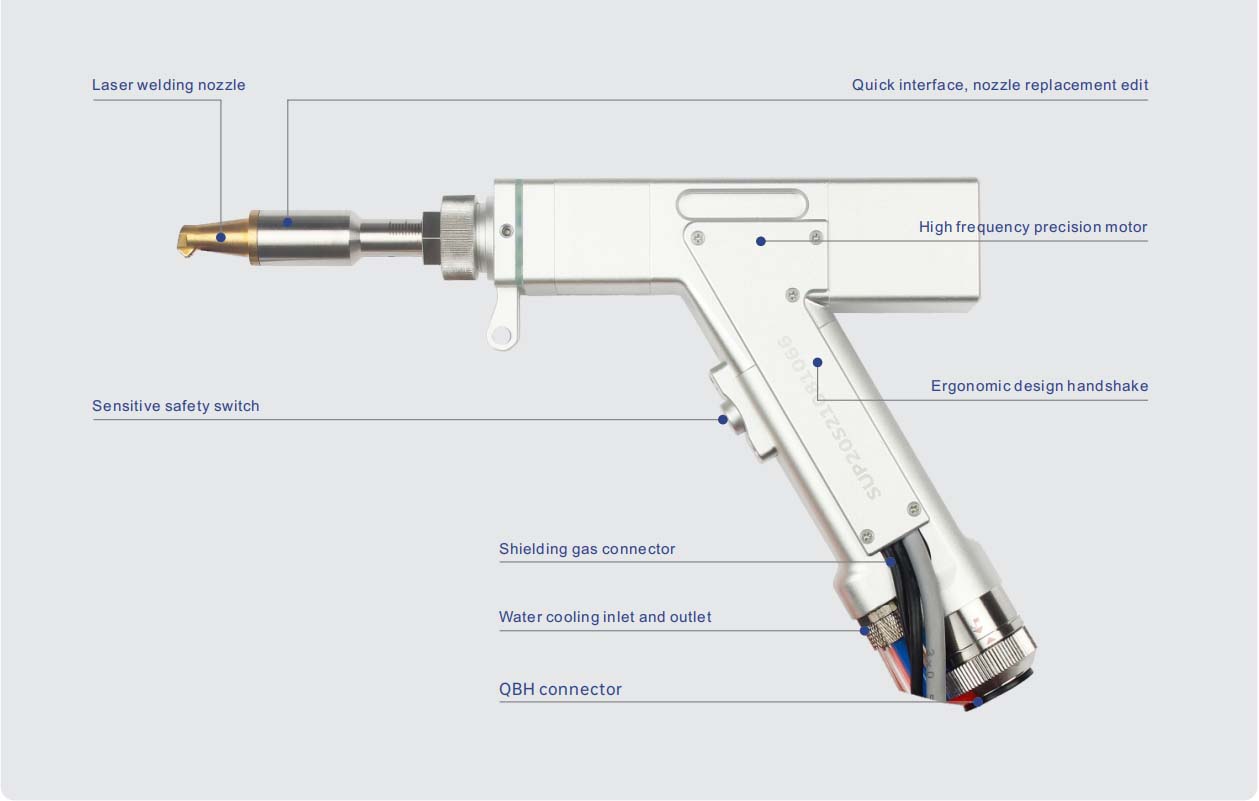

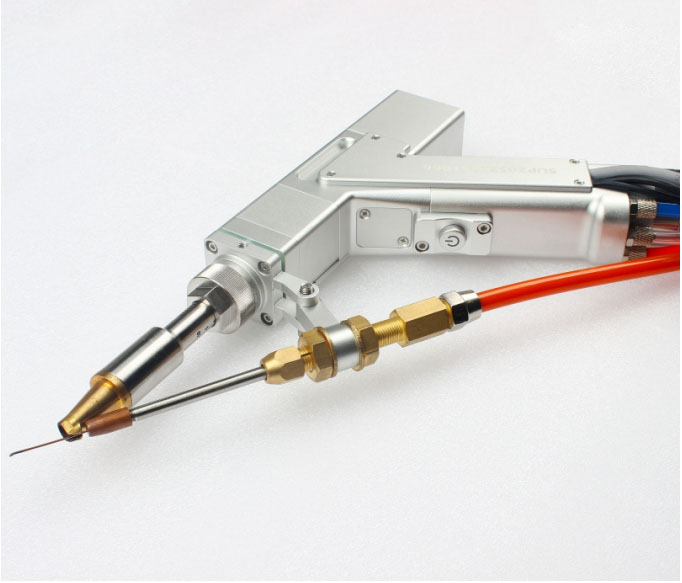

LASE R WEL D I N G G U N

Laser welding heads are widely used in complex and irregular welding procedures in industries such as stairs, elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel furniture, etc.; it perfectly replaces traditional argon arc welding, stainless steel, iron, aluminum and other metal materials Aspect welding.

Laser welding heads are widely used in complex and irregular welding procedures in industries such as stairs, elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel furniture, etc.; it perfectly replaces traditional argon arc welding, stainless steel, iron, aluminum and other metal materials Aspect welding.

The internal design is smart,the interactive control system expands the tolerance range of the processed parts and the width of the weld seam,it solves the disadvantage of small light spot and makes the weld seam better

Lightweight in shape, adopting body engineering design method, comfortable to hold; it's easy to control with one hand and easy to operate;

With multiple safety alarms, the light will be automatically locked after the workpiece is removed,the safety is high;

Beautiful welding seam, fast speed, no consumables, no welding marks, no discoloration, no need for later polishing;

A variety of angle nozzles can be confifigured to meet the welding needs of different products.

LASE R WEL D I N G N O ZZLE