Metal materials laser welding machine

Small cabinet fiber laser welding machine is good welding in metal materials, it's design to provide a high level of precision and accuracy in welding, perfect welding seams are attract many customers and manufactures, welding essential tool for industries that require accurate and reliable welding processes, makes much profits for them. One of the greatest advantages of small fiber laser welding machines is their ability to produce high-quality welds quickly and efficiently. These machines use advanced technology to create a focused laser beam that produces heat to melt the metal material, resulting in a strong and durable weld.

Video shows:

Machine's features:

1. The appearance of the model with simple and humanized design is convenient for customer operation.

2. The welding speed is 2-5 times than traditional welding machine.

3. Simple operation, common workers only need to train 2-5 hours can master the machine quickly.

4. Laser welding machine lifetime can reach up to 10000 hours.

5. Dotslaser adopts famous electric accessories(laser source, control board, servo motor) at home and abroad, trebling protective, modular control, ensure safe maintenance.

Parameter

NO. | Characteristics | Description | Notes

|

1 | Wavelength

| 1060-1080nm | |

2 | Power | 1500W | |

3 | Fiber length | 10m | Outer 8m |

4 | Welding gun weight | 0.8kg | |

5 | Cooling way | Water | |

6 | Use environment | Temperature 10-35°C, humidity 30%≦RH≦85%,no condensation | |

7 | Voltage | 220V±5%,50Hz | |

8 | Whole machine power | 7 kw | |

9 | Whole machine size | 950*520*800 | Portable small cabinet |

10 | Whole machine weight (kg±20) | 150 | Portable small cabinet |

11 | Safe degree | Class 4 | |

12 | Total power supply protective class | IP54 |

Applicable industries:

Metal welding, electrical switch housing surface welding, elevator welding, home appliance producing and welding, alloy door and window welding, kitchenware manufacturing. Welding machine also can weld various materials, such as carbon steel, alumimum alloy plate, galvanized sheet, silicon steel, stainless steel, copper and so on.

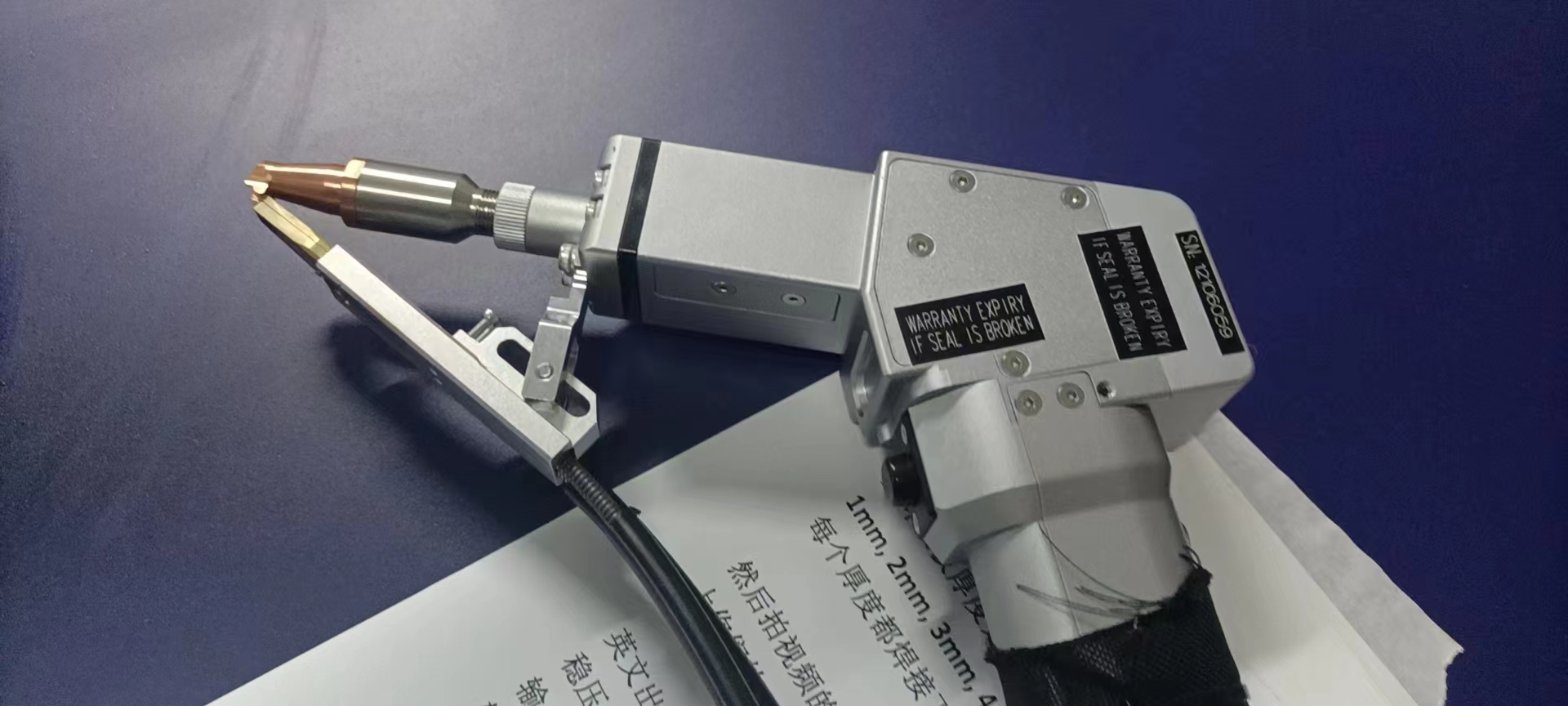

a. Laser welding gun

1. Portable,lightweight and convenient to use

2. 360° perfect laser welding, well control laser power, small spot can be obtained

3. Through the connection with laser, through the completely seal opticaled channel in the cavity, an energy spot is formed.

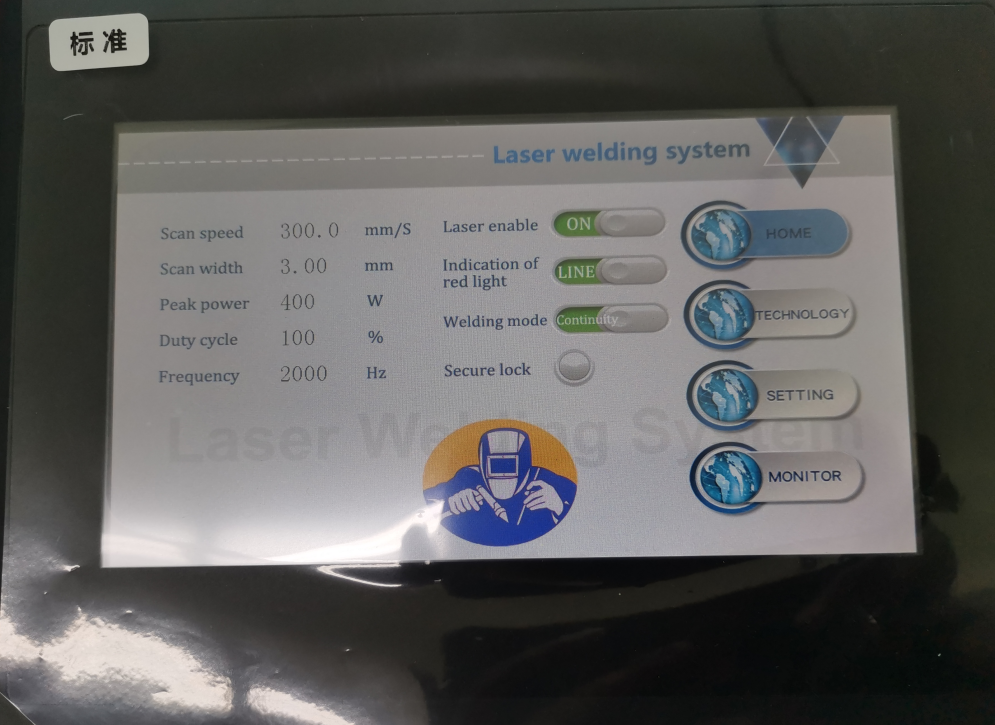

b. Control system

1. Easy to operate, support of variety of languages,suitable for various materials.

2. The main control screen of the welding machine can also control laser parameters and wire feeding parameter at the same time.

c. Wire feeder

Optional automatic wire feeding devices, software controlled, adjustable wire feed speed, filling the welding seam and increase the welding strength.

Machine's size

The working principle of laser welding machine:

The laser of the laser source is transmitted by the optical fiber line to the hand-held welding gun and then focused on the welding surface, which is absorbed by the carrier and converted into heat energy to melt the material or melt the welding wire to achieve the melting effect, and form a high-quality welding pass through the auxiliary inert gas protection, so that the two objects are firmly welded together. The water flow of the chiller is cooled to the laser and the hand-held welding head, which plays a role in protecting important components.

Sample

Certificate