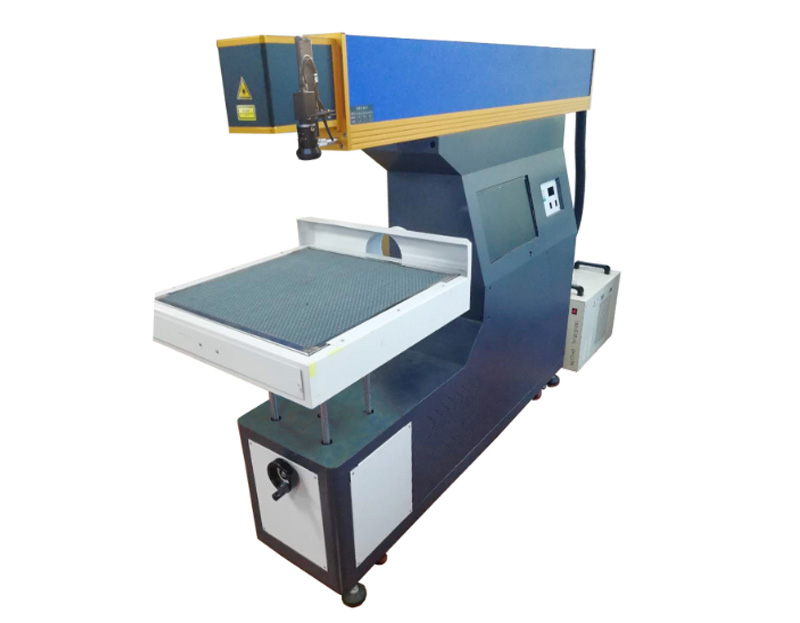

Small fiber laser welding tool

Smaller fiber lase welding machine with its precise welding and fast speed welding, many manufacturers and customers are like this machine, lightweight compact design is convenient to move and use. Laser welding machine also has wide range applications, such as it can weld metal, stainless steel, steel, titanium, galvanized steel and so on. Smooth and beautiful welding seam can be assured.

Video shows:

Machine's features:

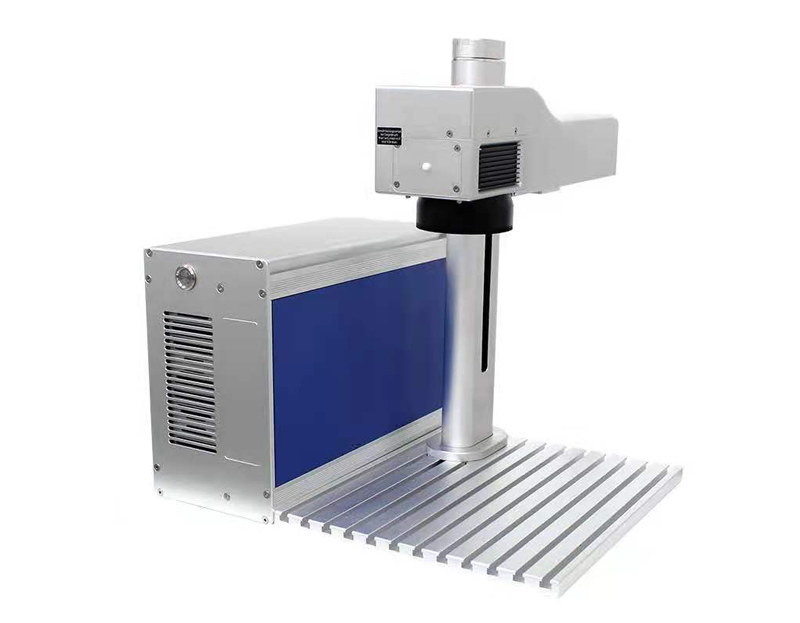

1. Compact design

Extremely small and beautuful, four roller casters help easy to move, less space occupied.

2. Perfect welding seam

Welding seam is smooth, firm and beautiful, not easy to deform, smooth welding surface with good touching experience.

3. Simple operation

Fast welding speed,easy to operate, flexible and convenient, long lifetime, safe and more environmentally, 360° without dead angles micro soldering.

Data sheet

Laser power | 1000W/1500W/2000W/3000W |

Laser wavelength | 1070±10nm |

Fiber length | Standard 10m maximum support 15m |

Working method | Continuous /modulation |

Speed range | 0-120mm/s |

Cooling | Industrial thermostatic water tank |

Working temperature | 15-35°C |

Working humidity | <70% no condensation |

Welding thickness | 0.5-3mm |

Welding gas requirements | <0.5mm |

Voltage | 380V |

Applicable industries:

Laser welding has giant market in mtal manufacturing and processing industries, such as metal welding, surface welding of electrical switch cabinets, elevator manufacturing, household appliance manufacturing,satinless steel stove,frame, doors and windows,fence,electric box, pipeline, and kitchenware manufacturing. Welding of various metal materials,such as carbon steel,aluminum alloy plate,galvanized plate, electrolytic plate, silicon steel, titanium alloy, galvanized aluminum plate,and reflective materials copper.

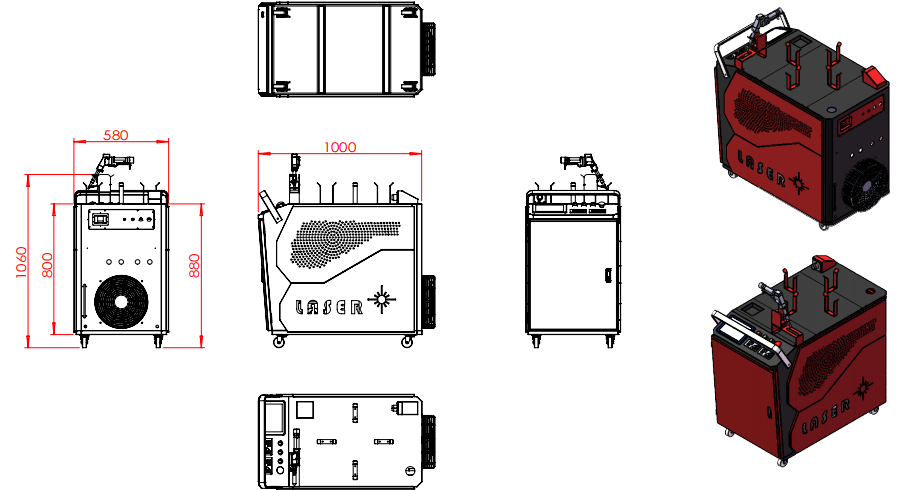

Machine's size

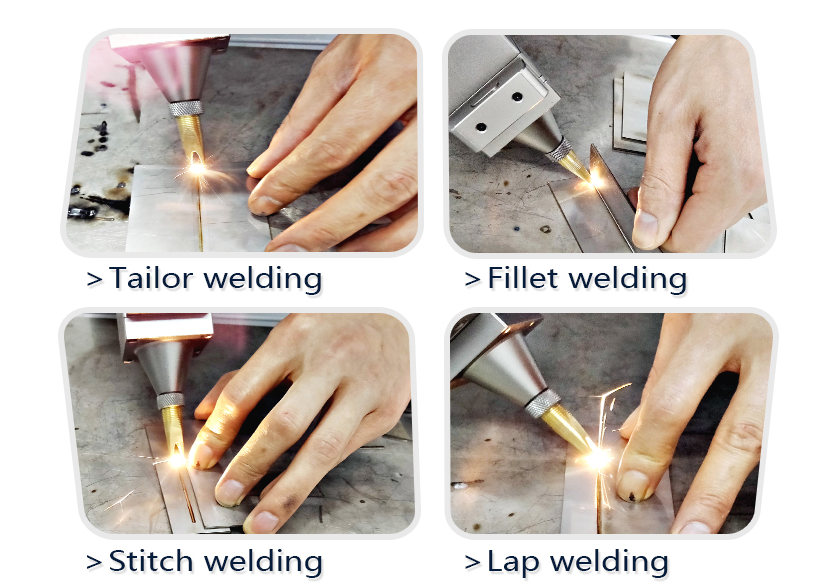

Suitable for different welding methods

Shipment and package

Certificate

FAQ

Q1. What metal can be welded with a laser welding machine?

A: They work well with common metals such as stainless steel, carbon steel, and aluminum. The precision of handheld fiber laser welding makes it an ideal choice for clean and strong welds across various metal types.

Q2: Is laser as strong as arc welding?

A: Yes, laser welding can be as strong as arc welding, and it is more efficient, nearly triple efficiency compared with traditional welding. Laser welding generally offers better accuracy and cleaner connections.

Q3: Does the laser welding machine require gas?

A: Laser welding typically requires gases suchas nitrogen or argon. These gases protect the molten metal from the effects of air and enhance the laser welding process. This is crucial for achieving precise and high-quality welds.