stainless steel aluminum alloy sheet portable laser welding machine

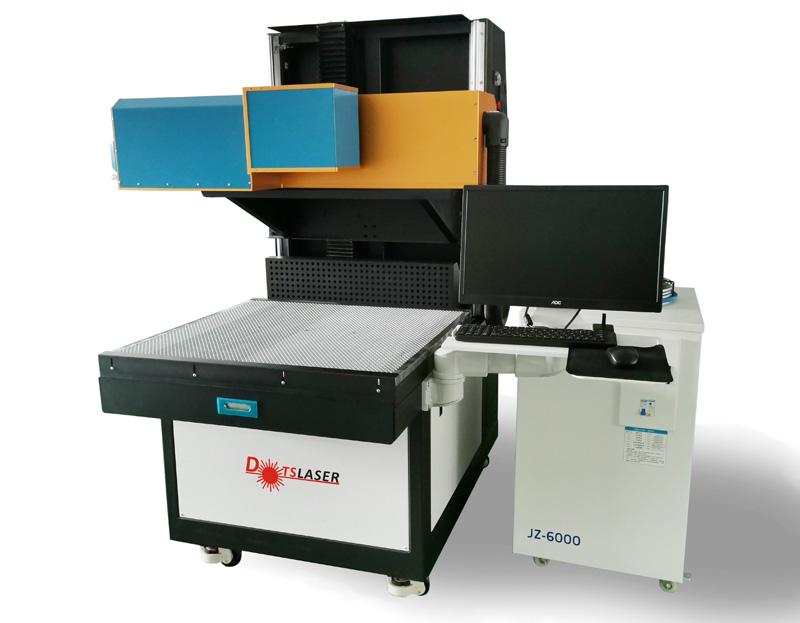

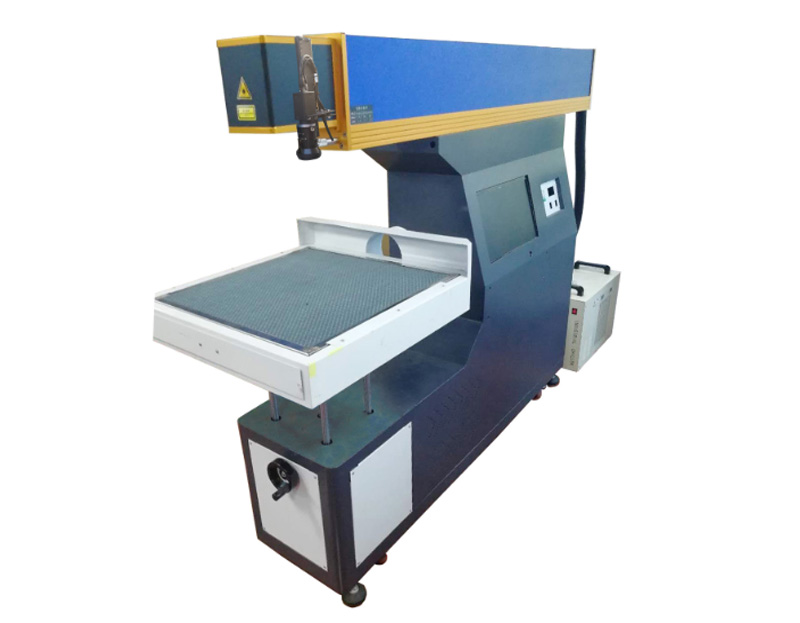

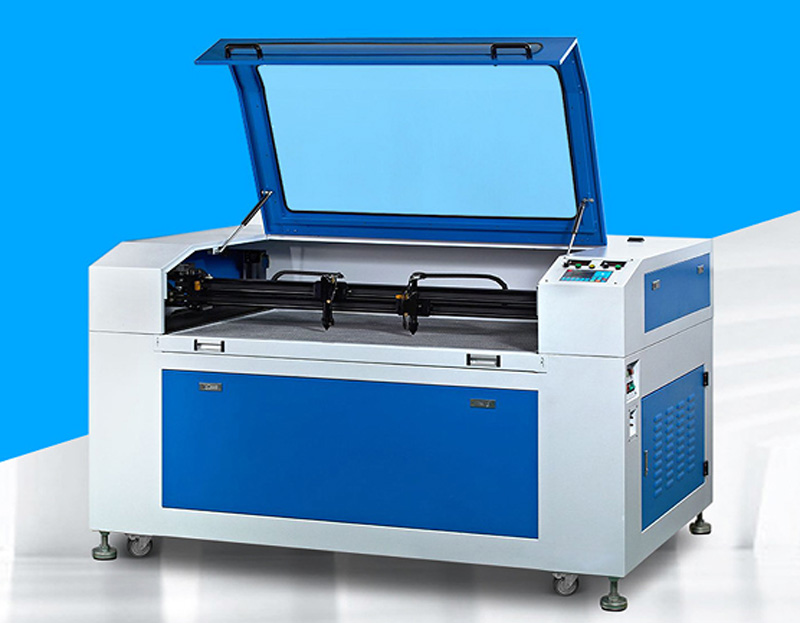

Model option: DS-LW1000,DS-LW1500,DS-LW2000,DS-LW3000. Various cabinet styles to choose, Raycus,MAX,JPT,BWT laser source can be selected. SUP, Qilin,Raytools or other welding gun can be selected. Hanli,S&A or other brand water chiller can be selected.

Stainless Steel Aluminum Alloy Sheet Portable Laser Welding Machine

Features and advantages.

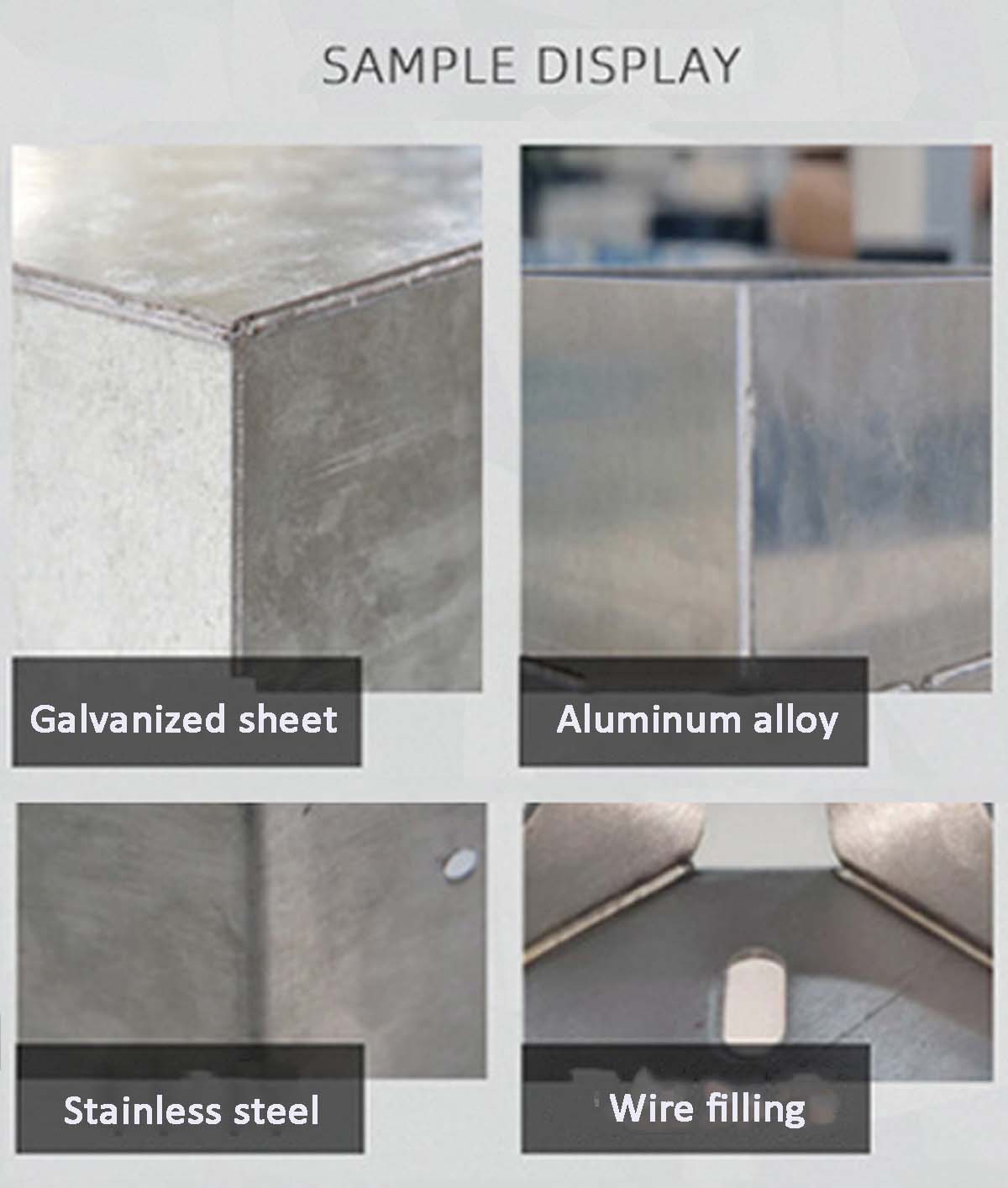

Weld firmly. high penetration keep welded seam firm

Weld seam smooth, almost no need polishing.

Simple and easy to operate, even if you have no any experience in welding, you can also learn to use it in short time.

Product introduction.

Model: DS-LW1000, DS-LW1500, DS-LW2000, DS-LW3000

Laser power: 1000W, 1500W, 2000W, 3000W

Laser type: CW mode, 1064nm, fiber laser beam.

Welding speed: 0~120mm/sec

Penetration:

Stainless steel: 1.8mm/3mm/3.9mm/5mm

Carbon steel: 1.75mm/2.95mm/3.8mm/4.8mm

Aluminum alloy:1.0mm/2.1mm/3.5mm/4.0mm

Auto wire feeding: 0.8-1.2mm wire/0.8-1.6mm wire/0.8-1.6mm wire/0.8-1.6mm wire

Power consumption: ≦3KW/≦4.5KW/≦6KW/≦8KW

Voltage: 220V/220V/380V/380V

Application: suit for welding various metallic sheet within 1~5mm thickness.

Product advantages.

Portable handheld laser welding

The operation is simple, and ordinary people can get started in half an hour. The labor cost is low and the speed is fast. The welding speed is 5 to 10 times that of traditional argon arc welding, which is equivalent to saving the labor cost of 3 to 5 welders.

Concentrated energy, little influence of thermal deformation, fine and beautiful weld seam, deep molten pool and high strength. It can weld very thin materials, and it can be welded with filler wire or without wire.

Traditional argon arc welding:

High professional technical requirements, high labor costs, workers are prone to occupational diseases and serious physical injuries.

The speed is slow, the efficiency is low, the heat influence is large, and the welded workpiece is easily deformed.

The weld seam is thick and irregular, and requires secondary grinding, which has great limitations and cannot weld too thin materials.

There are consumables, wire filling is required, and there are air holes, which are easy to weld through.

Continuous laser mode, smooth weld seam, no fish scale pattern, firm weld seam.

The welding heat-affected zone is small, the yellow and black areas on both sides of the weld are small, and the overall deformation of the workpiece is small.

The surface of the weld seam has a small pile height, no need for secondary grinding treatment, reducing labor and time costs.

Product detail.

Workshop show