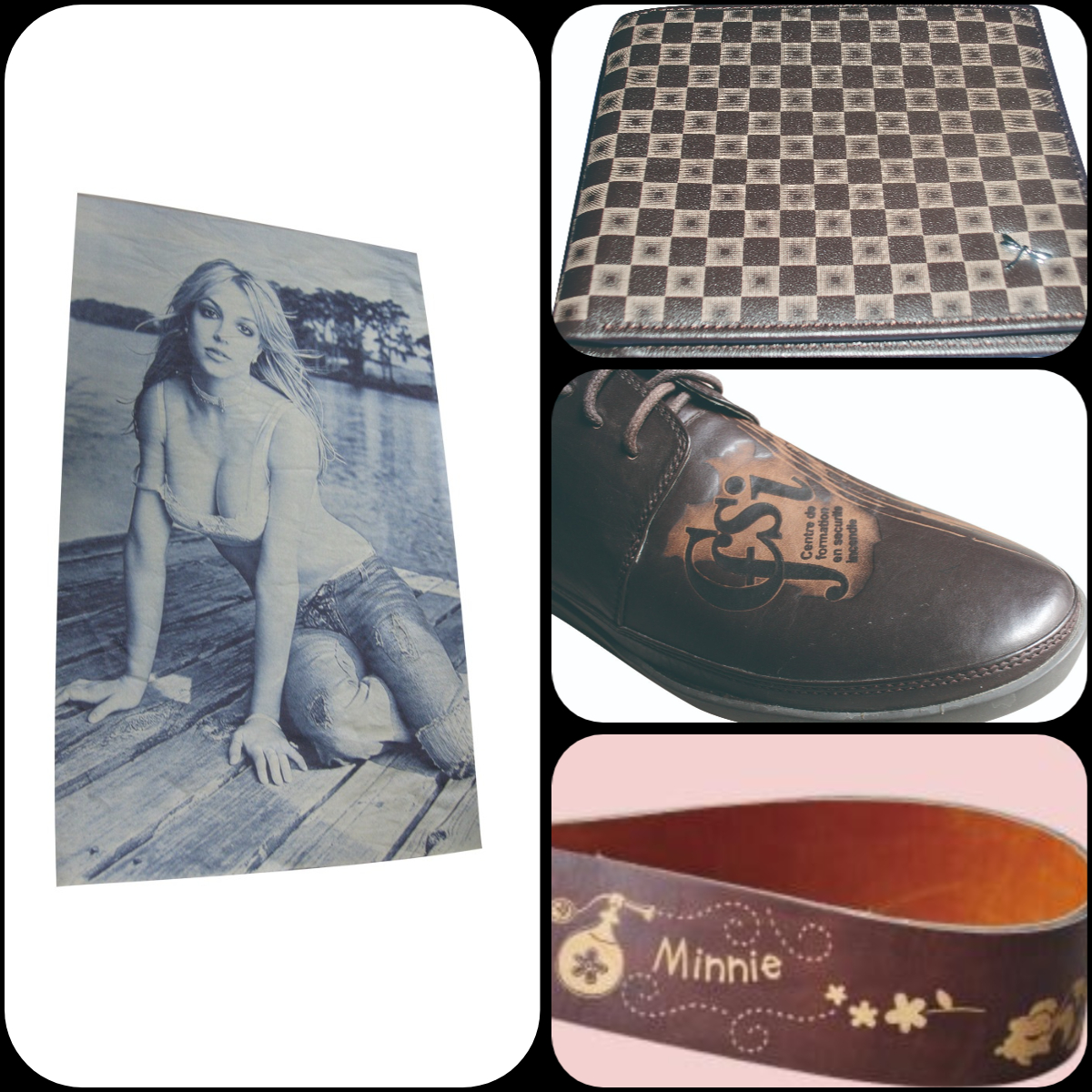

CO2 laser mark on leather garments

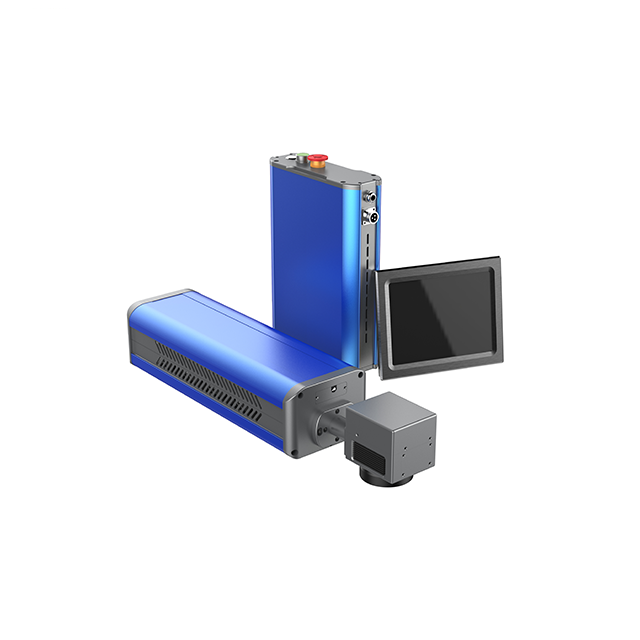

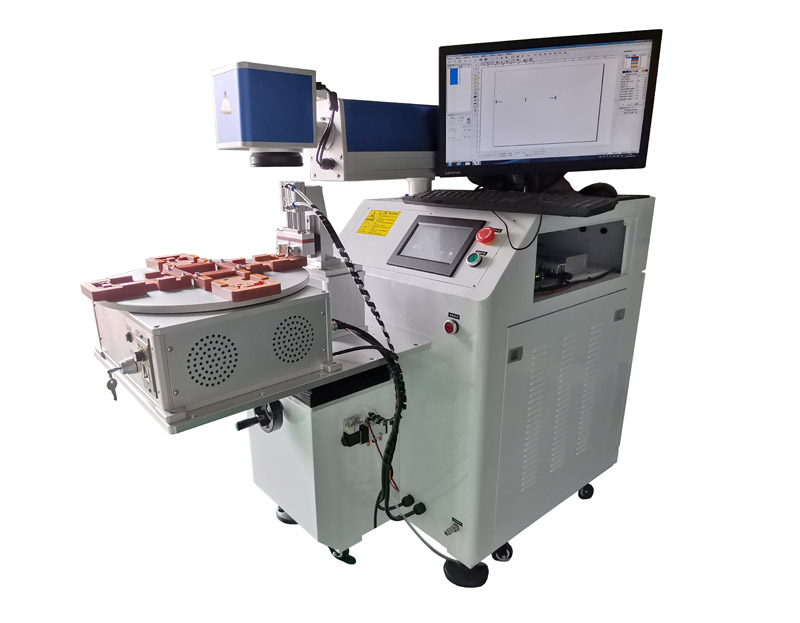

CO2 laser on the fly marking machine is design for high speed continuous production line, enabling precise marking on moving workpiece, widely use in industrial manufacturing, it integrates with convert belts help faster the processing time and increase the production greatly. CO2 lase flying machine has wide applications, such as wood, rubber, paper, bamboo, cloths, stone, metal sheet.

Video shows:

Parameter

Model | DS-LMC30

|

Laser power output

| >30W

|

Laser wavelength

| 9.3μm/10.6μm

|

Marking area

| 100x100mm(standard)

|

Pulse frequency

| 1~100KHZ

|

Laser type | CO2 |

CNC or Not | Yes |

Warranty | 1 year |

Max marking speed

| 12,000mm/s

|

Font format

| Dot,single line,True type

|

Code format

| Most 1D&2D codes available

|

Supported interface

| USB,TCP/IP,RS219 for encoder and sensor

|

Repeat accuracy

| ±0.001mm

|

Min.line width

| 0.1mm

|

Min.character size

| 0.2mm |

Cooling

| Air cooled |

Working temp

| 5~35℃

|

Power supply

| AC220V±10%, 50HzorAC110V±10%,60Hz

|

Gross weight

| 90KG |

What're the advantages of laser marking on leather products?

1. Mass production in short time

Flying laser marking machine uses continuous laser marking methods, 24 hours working, save a lot of processing time and labor cost, help to conduct mass production in short time, increase productivity for the factory.

2. Precise marking

The CO2 laser flying marking machine has equipped with high speed galvanometer scanning system, high speed and high accuracy are basic features of this machine, stable marking performance offers perfect marking effect.

3. Continuous processing

The on the fly laser marking machine can work for lasting 24 hours,automatic working methods saves much of processing time and labor cost, non-contact processing ways without producing consumables, no damage to the material.

Applications:

Flying marking usually mark on suface of non-metallic materials, such as rubber, ceramic, wood, paper, stone, organic, arylic, plastic, leather, cloth.

Electronic industry: laser flymarking of capacitors ,inductors, printed circuit boards, integrated circuits, electrical plug-in cards, various instruments and control panels;

Daily necessities and clothing industry: marking buttons, cosmetic packaging, food packaging, tobacco and alcohol, stationery, handicrafts, etc.

Samples

Shipment and package

Certificate

FAQ

Q1:What is flying CO2 laser marking machine?

A: Flying CO2 laser marking machine is high-tech devices for marking or engraving most non-metallic materials, such as wood, paper, ceramic, stone, plastic, rubber. The flying CO2 laser marker requires minimal maintenance, cost-effective, non-contact method does not require any chemicals or inks.

Q2: How fast can a CO2 laser marking products?

A: The marking speed of CO2 laser marking machine can very depends on power output of the laser and the complexity of the design being marked. Its max marking speed can reach up to 12000mm/s.

Q3: What is the maintenance required for a CO2 laser marking machine?

A: Regular maintenance, usually cleaning the lenses replacing the worn parts, is require for optimal performance and longevity for a CO2 laser marking machine. CO2 laser marking machine need less maintenance than traditional marking machine.

Q4: Is it possible to customized the marking design using a CO2 laser marking machine?

A: Yes, many CO2 laser marking machine offers full customization capacities, allowing users to creat unique and special marking design.