Why people prefer laser marking?

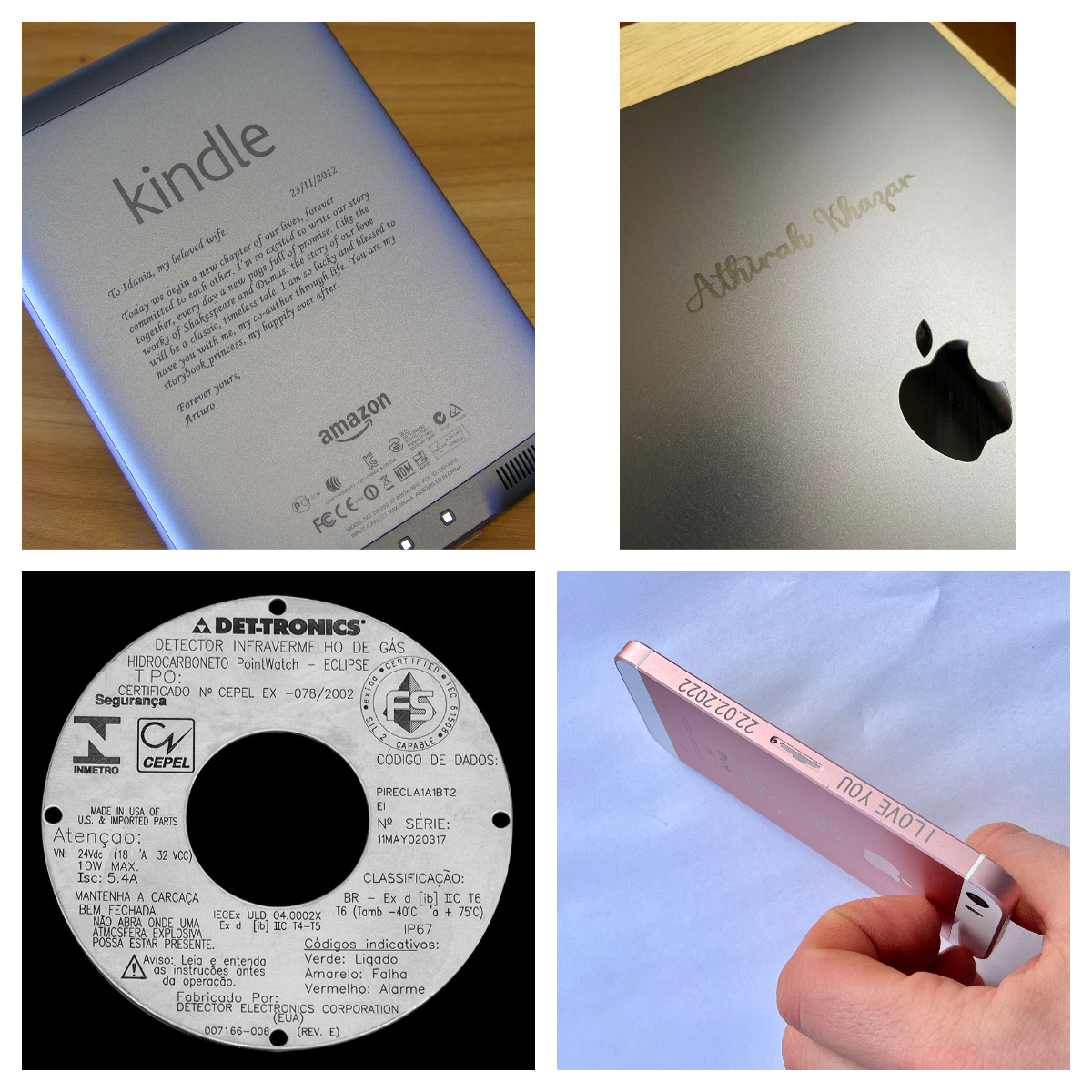

Laser marking on electronic products offers permanent and high-contrast marking. Tiny text can be engraved well by a laser marker, even with 3D techniques to engrave. Laser engravers enable marking on phones, iPads, personal computers and earphones. They can mark on every electronic product surface.

Laser marking on phone:

Steps: Laser engraving on electronic products

1. Identify the materials

The first step is to identify your phone's materials so that you can choose the correct laser. A fiber laser machine is more suited to engrave metal, aluminum, and stainless steel products. CO2 lasers are preferred for engraving wood, paper, and stone, while UV lasers are more suitable for engraving glass and delicate marking.

2. Design the engraving

Design the engraving model according to your phone's dimensions, put your design into the engraving software, and set correct parameters.

3. Test engraving

Before you start, please process a test engraving on your samples to reduce the risk of damaging the raw materials.

4. Start engraving

When you finished the above steps, set the correct parameter and start engraving.

5. Finished engraving

When finished engraving, pay attention to the sample's surface, clean the item's surface, and wipe any dirty areas.

Laser marking samples:

Fiber laser applications:

1. Laser marking:

Fiber laser with 1064nm laser wavelength, which is greatly marking on metal, copper, satinless steel,titanium materials products, such as stainless steel pot, phone back surface, windows.

2. Laser welding:

Lasre welding provides faster speeds, greater precision, lower deformation, higher quality and efficiency compared to traditional methods. Flawless welding seam has attracted many customers and manufacturers

3. Laser cutting:

Laser cutting can handle with complicated cutting edge smoothly, this makes it optimal for parts with close tolerances.

4. Laser cleaning:

Fibre lasers can effectively clean metal surfaces of paint, oxide, rust, etc. The process can be automated and customised for different production line parameters.

Previous: None

Next: Why is Fiber Laser Engraving Not Ideal for Wood Products