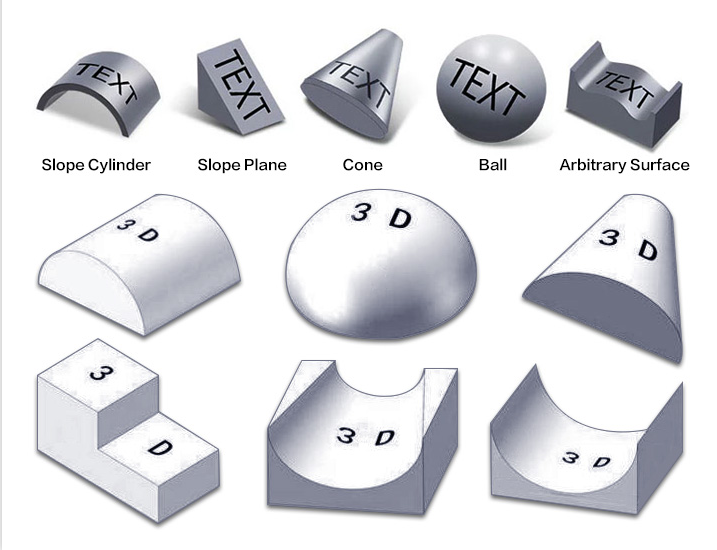

3D laser marking displays:

3D techniques laser marking:

1. 3D laser marking techniques are advanced technologies that use lasers to mark objects in three-dimensional space. Unlike traditional 2D laser marking, 3D laser marking can create permanent, precise and detailed marks on the surface of objects with complex geometries.

2. One of the main advantages of 3D laser marking techniques is their versatility. They can be used on a wide range of materials, including metals, plastics, ceramics and glass. Additionally, because the process is computer-controlled, it can be customized to mark objects with specific designs, logos, or text, making it a useful tool in brand and product identification.

3. Another benefit of 3D laser marking is its speed and efficiency. The process is automated, which means it can be completed quickly and consistently without the need for manual intervention. This saves time and reduces the risk of errors.

3D laser marking samples

Unique application:

The 3D laser marking machine is suitable for application on inclined surfaces, step differences, cylinders, cones, spherical surfaces, and curved surfaces that could not be realized by ordinary marking machines in the past. The 3D laser texturing machine has a long service life, is easy to maintain, and has a fast marking speed, which greatly improves working efficiency.

Applicable industries:

1. Electronic Components: Resistance, capacitance, chips, printed circuit boards, computer keyboard.

2. Apparatus & Meter: Panel signs, precision equipment.

3. Instrument: Panel signs nameplates, fine marking.

4. Hardware Tools: Knives, tools, measuring tool, cutting tool.

5. Automobile Parts: Pistons, piston rings, gears, shafts, bearings, clutch, lights.

6. Mechanical Parts: Bearings, gears, standard parts, motors.

7. Daily Necessities: Handicrafts, zipper, key holder, sanitary ware.

8. Jewelry: Rings jewelry, gold, silver.

9. Food & Drinking Packing: Plastic packings, metal packings.

Versatile angles 3d laser marking