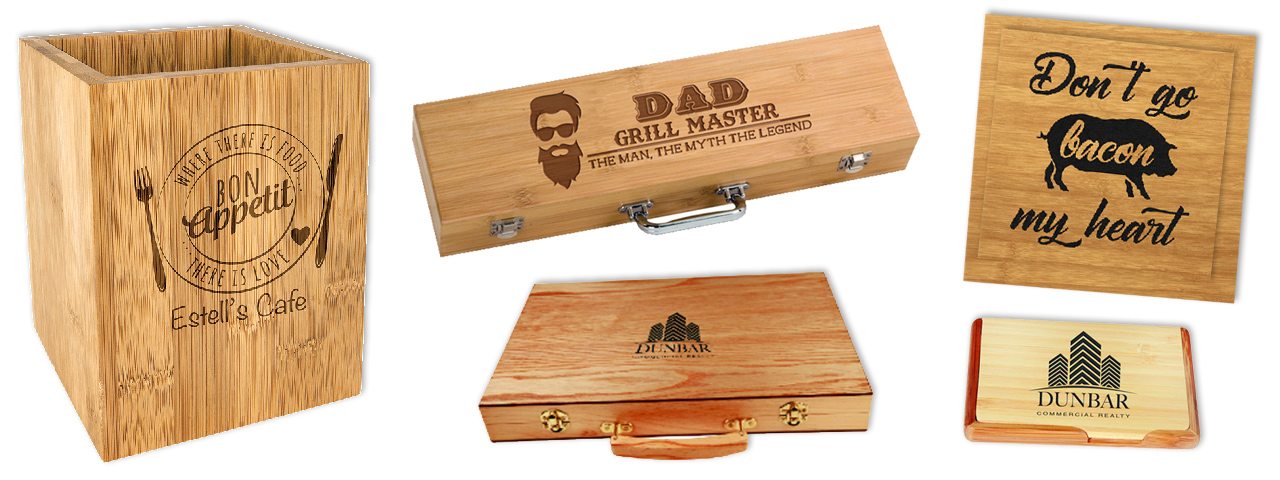

CO2 laser engraving on wood box display:

What is a fiber laser?

Fiber laser with 1064 nm wavelength, suitable for marking metal, fiber lasers are known for their high efficiency, excellent beam quality, and compact design.

Fiber lasers are widely used in various applications, including material processing, telecommunications, medical devices, and research.

1. Doped Fiber: The core of the fiber laser, where the lasing action occurs.

2. Pump Diodes: Provide the energy to excite the dopant ions.

3. Fiber Bragg Gratings (FBGs): Act as mirrors to form the optical cavity.

4. Optical Isolators: Prevent back-reflected light from destabilizing the laser.

1. High Efficiency: Fiber lasers convert electrical energy into laser light with high efficiency.

2. Excellent Beam Quality: The fiber's waveguide properties ensure a high-quality, diffraction-limited beam.

3. Compact and Robust: The all-fiber design makes these lasers compact and resistant to misalignment.

4. Thermal Management: The large surface area to volume ratio of the fiber allows for effective heat dissipation.

Why fiber laser not suitable for marking wood?

1. Material Interaction: Fiber lasers are primarily designed for marking and engraving metals and some plastics. Wood, being an organic material, reacts differently to the high-intensity light of a fiber laser.

Instead of cleanly vaporizing the material, the laser can burn the wood, leading to charring and uneven marks.

2. Heat Sensitivity: Wood is highly sensitive to heat. The intense heat generated by a fiber laser can cause scorching, discoloration, and even ignite the wood in some cases.

3. Surface Finish: Fiber lasers are better suited for materials with smooth, hard surfaces. Wood, especially when unfinished or with a rough texture, can result in inconsistent engraving depths and uneven surface finishes.

4. Wavelength: Fiber lasers typically operate at a wavelength of around 1064 nm, which is optimal for metals but not for organic materials like wood.

5. Engraving Depth and Detail: Achieving fine details and consistent engraving depths on wood is more challenging with a fiber laser. The risk of burning and uneven material removal can compromise the quality of the engraving.

6. Safety Concerns: Engraving wood with a fiber laser can produce smoke and potentially harmful fumes, especially if the wood contains resins, oils, or other chemicals. Proper ventilation and safety measures are required, but this adds complexity to the process.

FAQ about fiber laser engrave wood:

Fiber lasers excel on coated woods or thin veneers, offering precise and consistent markings without the worry of burns or uneven results.

Typically, fiber lasers are not specifically intended for woodworking, but they can be used to create intricate designs and markings on treated or coated wood surfaces.

It depends on your needs. CO2 lasers are perfect for deep engraving and wood cutting, whereas UV lasers excel in intricate and delicate designs. Fiber lasers, on the other hand, are highly versatile for various materials but have limitations when it comes to working with wood.

Previous: Laser engraving on electronic products