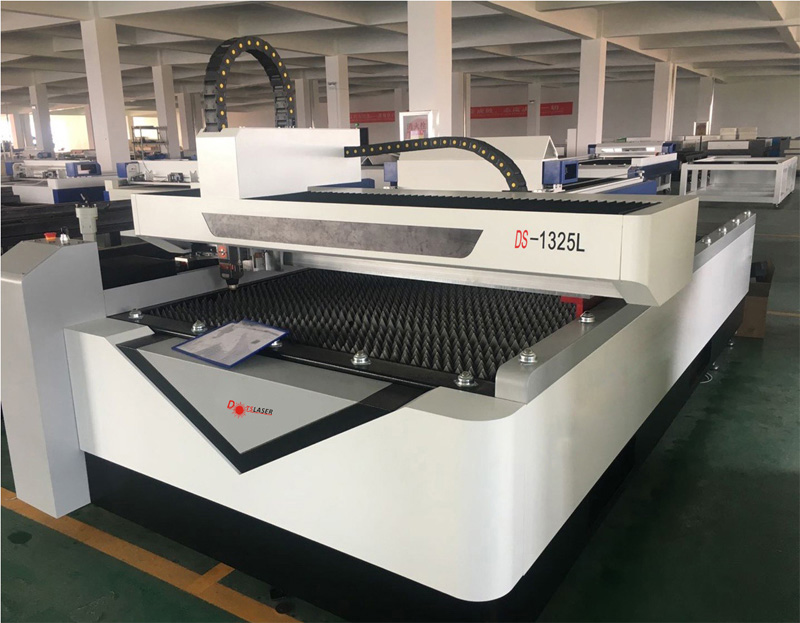

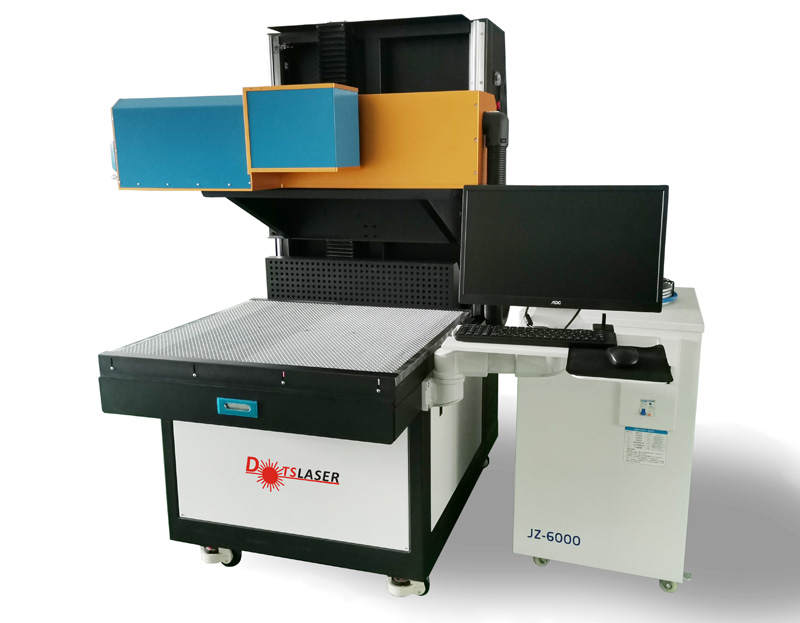

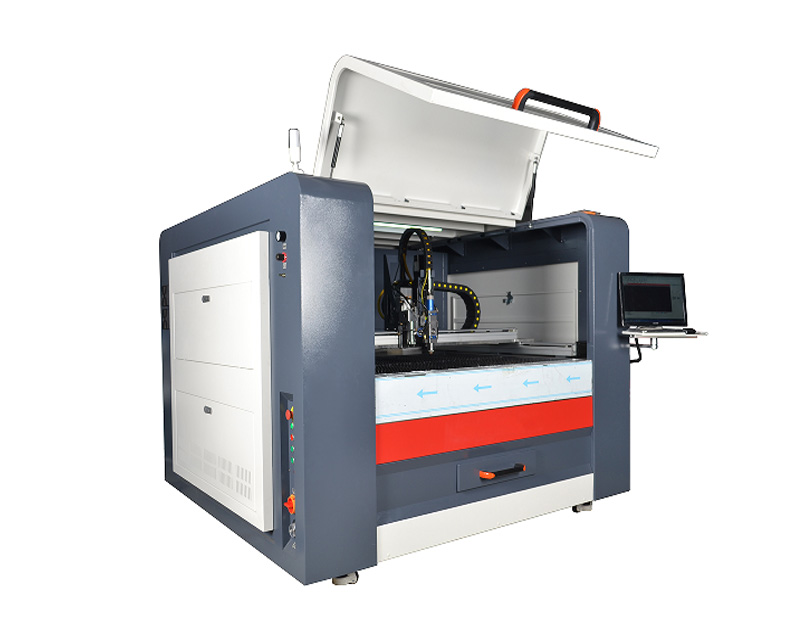

High Precision laser cutter tool

High precision laser cutting machine is very welcomed in the laser machine market. Due to its high precision and excellent cutting accuracy , it performs well in many materials, such as metal, metal alloy, aluminum, titanium, gold, silver, wood, plastic and so on. Saving cost and less comsumables, suitable for mass production, increase productivity greatly, it's the best solution for cutting hard materials.

Video shows:

Machine's feature

1. Precision

Laser cutting machines offer unparalleled precision and accuracy, allowing for even the most intricate designs to be cut with ease. This level of precision ensures that the final product is of the highest quality and meets all required specifications.

2. Versatility

Laser cutting machines can cut through a wide range of materials including metal, plastic, wood, fabric, and more. This versatility makes it a great choice for a variety of applications across many different industries.

3. Speed

Laser cutting machines are incredibly fast, able to cut through materials at a much quicker rate than traditional cutting methods. This means that projects can be completed much more quickly, improving efficiency and productivity.

4. No Physical Contact

Laser cutting machines use a non-contact cutting method, which means there is no physical contact between the machine and the material being cut. This eliminates the risk of distortion, warping, or damage to the material, ensuring a perfect, clean cut every time.

Parameter | ||

Model | DS-6060 | |

Power | 1500W | 2000W |

Wavelength | 1064nm | |

Speed | 250m/s | |

Cutting speed | According to materials | |

Recommend thickness | ≤2mm(gold)

| ≤2mm(gold)

|

Cutting line width | 0.05-0.15mm | |

X/Y axis positioning accuracy | ±0.03mm | |

X/Y repeat positioning accuracy | ±0.03mm | |

Working area | 600x600mm | |

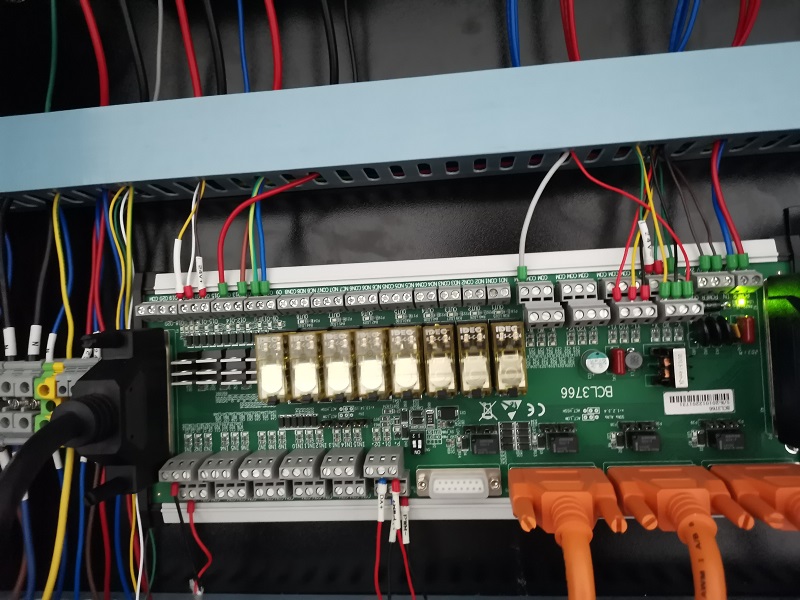

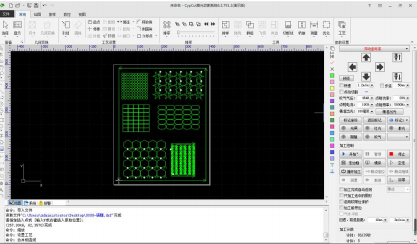

Cutting system | Cypcut cutting system | |

Support format | DXF,CDR... | |

Gas supply condition | <2.5MPa | |

Whole machine power | ≤10KW | ≤12KW |

Use environment | Room temperature below 35℃, dry environment without oil and water pollution dust, ventilation | |

Voltage | AC 220V 50Hz/60Hz

| AC 380V 50Hz/60Hz

|

Weight | <1200kg | |

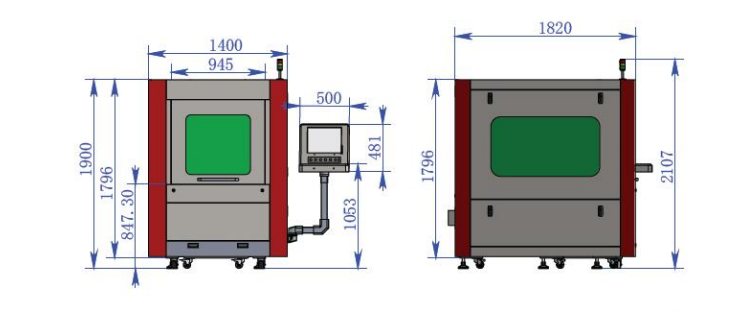

Machine's size

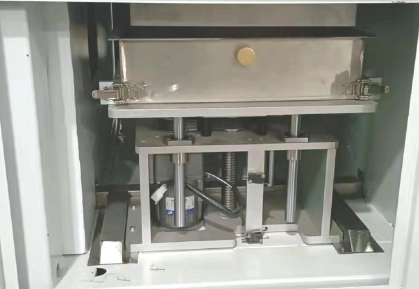

Main components

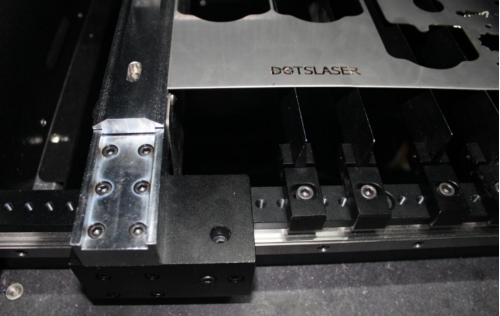

1. Adopt marble workbench, stable and reliable cutting performance,excellent positioning accuracy, suitable for long time process.

2. Use universal software, cutting path automatic optimization, support many kind of file formats,such as DXF, Gerber, AI......

3. Professional recovery system, precise gold recovery rate reach up to 99%, discrease customer's cost consumables greatly, fully structure design, stable performance, no pollution.

4. Dotslaser customized laser source, optimized laser source according to cutting techniques, its performance as the same as the imported laser source.

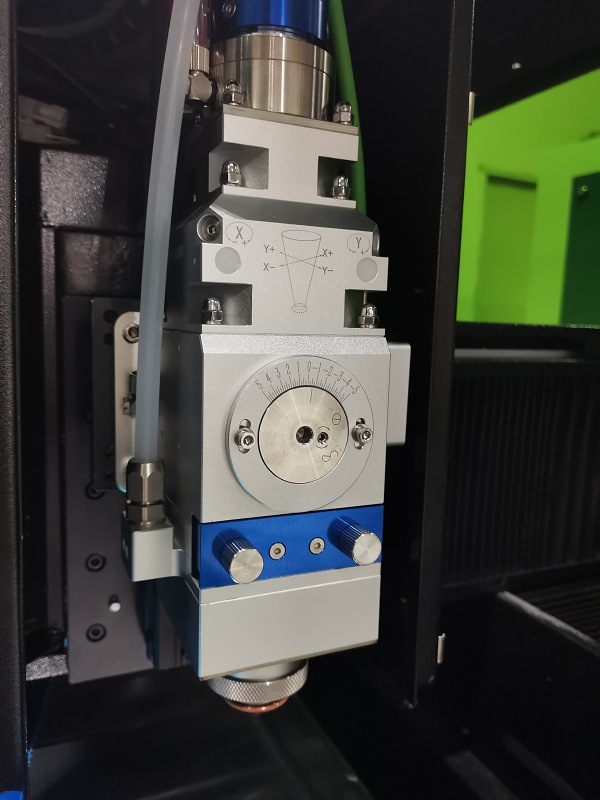

5. Dotslaser customized laser head,adjusting laser head parameter, reach the high-density reactive materials best solution.

Applicable industry

1. Manufacturing Industry

Laser cutting machine used to cut metals, sheet metals, and other materials needed for the manufacturing process. The precision of these machines makes them ideal for creating intricate shapes and designs that cannot be achieved through traditional cutting methods.

2. Automotive Industry

The automotive industry relies heavily on laser cutting machines to manufacture car parts. These machines are used to cut through different types of materials such as steel, aluminum, plastics, and carbon fiber composites. The precision of laser cutting machines ensures that the car parts produced are of high quality and up to the desired standards.

3. Aerospace Industry

The aerospace industry uses laser cutting machines to manufacture aircraft parts. The high precision of these machines ensures that the parts produced are of the highest quality and improve the industry standards. The use of laser cutting machines in the aerospace industry has reduced manufacturing time and increased efficiency.

4. Medical Industry

Laser cutting machines are also used in the medical industry. They are used to manufacture medical equipment, surgical instruments, and implants. The precision provided by laser cutting machines ensures that these medical products are of high quality, accurate, and safe to use.

5. Signage and Advertisement Industry

Laser cutting machines are also used in the signage and advertisement industry. They are used to cut different types of materials such as plastic, wood, and fabric to make signs and promotional materials. The precision of laser cutting machines ensures that the signs and promotional materials are of high quality and eye-catching.

6. Architecture and Interior Design Industry

Laser cutting machines are also used in the architecture and interior design industry. They are used to cut different materials such as wood, metal, and plastic to create intricate designs and patterns. The precision of laser cutting machines ensures that the designs produced are of high quality, and the end products are aesthetically pleasing.

Samples

Shipment and package

Certificate