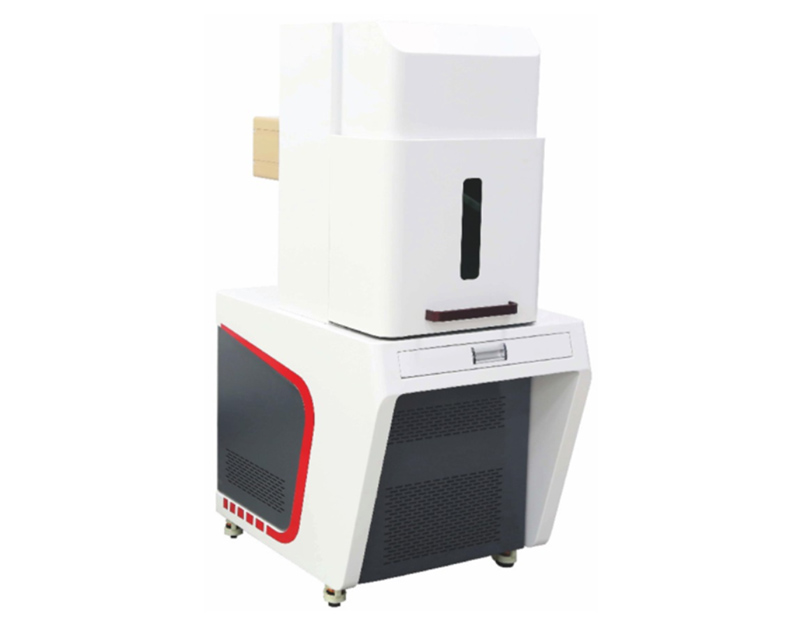

3D UV LASER engraving machine

"DS-UV5" 355nm UV laser marking machine adopts the high-speed servo precision scanning galvanometer system and professional control software. It is the high-tech product integrated laser technology, precision machinery, electronics, computers and other disciplines. It is widely used for precision marking, cutting and micromachining for various of glass, LCD, textile, thin ceramic plate, semiconductor silicon wafer IC grain, sapphire, polymer film, etc. The features are large output, small size, high precision, high speed, good Stability, absence of harmful substances, low noise development, low consumption, material consumption, etc. The control software with the English WINDOWS interface is easy to use.

Introduction

"DS-UV5" 355nm UV laser marking machine adopts the high-speed servo precision scanning galvanometer system and professional control software. It is the high-tech product integrated laser technology, precision machinery, electronics, computers and other disciplines. It is widely used for precision marking, cutting and micromachining for various of glass, LCD, textile, thin ceramic plate, semiconductor silicon wafer IC grain, sapphire, polymer film, etc. The features are large output, small size, high precision, high speed, good Stability, absence of harmful substances, low noise development, low consumption, material consumption, etc. The control software with the English WINDOWS interface is easy to use.

Applicable Industry

It is good for engraving on the surfaces of bottles for cosmetics, pharmaceuticals, food and other high-molecular materials are marked with fine effects and clear and firm markings. Better than ink coding and no pollution; flexible pcb board marking, dicing; silicon wafer micro hole, blind hole processing; LCD liquid crystal glass two-dimensional code marking, glass surface punching, metal surface coating marking, Plastic buttons, electronic components, gifts, communications equipment, building materials, and so on.

Electronic components, integrated chips, electrical appliances, communication equipment, tools, precision machinery, frames, watches and clocks, auto parts, crystal glass marking, plastic cases ETC.

Advantage:

1. Focused UV light spot size is small,heat-affected area during processing is minimum,So it is used in ultra fine and special material’s marking.

2. 3D function ,step engraving ,curve engraving ,any surface engraving .

3. Since UV laser did not produce any thermal effects and burning issues, the result of the marking is precise ,smooth and steep.

4. A lot of material will absorb UV light at 355nm except Copper, so UV laser are suitable for processing more types of material .

5. Portable, all-in-one machine,saving space.

6. Multiple Marking form: Rotating Marking.Multistage Marking.

7. Support different file formats: PLT, AL, DXF, BMP, JPG and so on.

8. OEM customization can be accepted.

Property

●Choose the laser that is suitable for the power or power density of the material being processed, it can be processed on most non-metallic materials.

● Laser is processed in the non-mechanical "tool", no mechanical extrusion and stress on the material, no tool wear, no toxins, no pollution.

● Low material consumption, no thermal deformation.

● Easy to handle. The use of Computer Numerical Control technology enables automated processing. It is a high speed and efficiency machine for the accessories in the production line and as part of the flexible manufacturing system.

● High machining precision. Precise positioning with the three-dimensional workbench.

● High protection against forgery.

●Low costs. It is true that the one-off investment is higher, but with a large number of continuous machining operations, the cost of each part can ultimately be made extremely low, resulting in a high level of benefit.

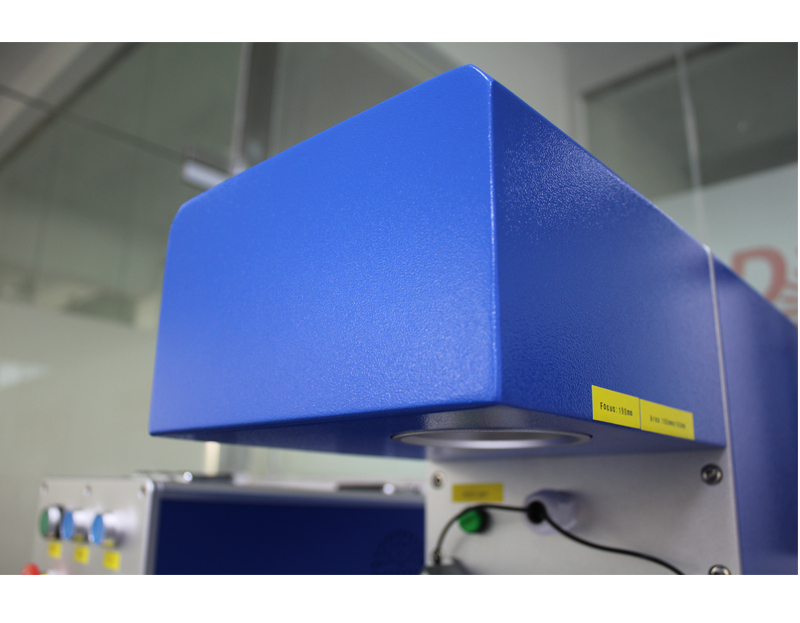

Structure and principle

The "DS-UV5" of the 355 nm UV laser marking machine consists of a power supply for laser source,control card,motor driver,and galvanometer, an XYZ axis galvanometer system, an optical system, a software operating system, Z axis stand, and precise positioning of the work table.

The laser beam output from the laser resonator at a wavelength of 355 nm is then expanded by the beam expander,focused automatically by the Z-axis galvanometer and then reflected by the X-axis, Y-axis galvanometer scanning system, which reaches down to the materials through the optical focusing lens. Under the computer control, a galvanometer scanning system oscillates quickly, which scans the laser beam in the X and Y directions. The surface on which the laser beam is focused is marked. After the continuous process under computer control, preprogrammed characters and patterns are marked on the surface of the material.

Samples