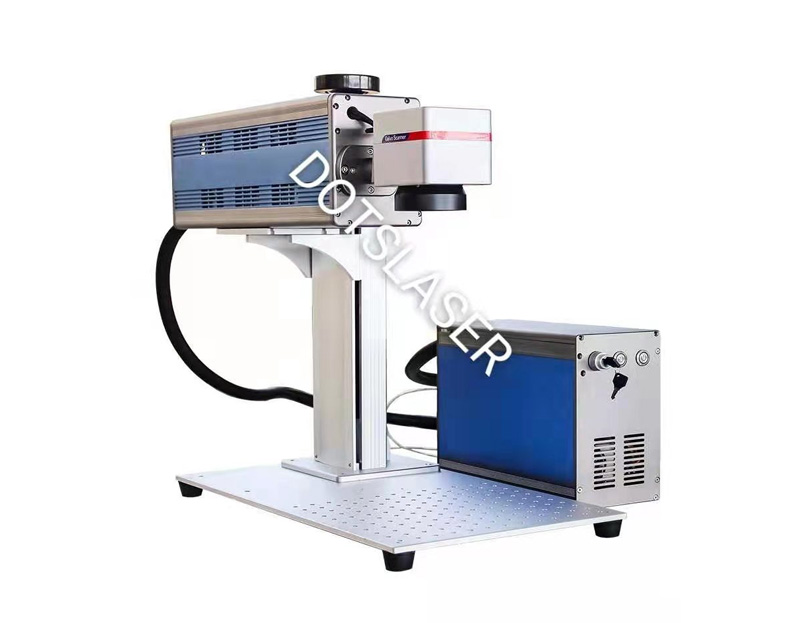

Glass UV laser marking machine

UV laser machine is equipped with a high speed galvanometer scanning system and professional control system. It is a high-tech precision machinery wirh integrated compact design, it is widely used for precision marking, cutting and micromachining for various of glass, LCD, textile and thin ceramic plate, semiconductor silicon wafer IC grain, sapphire, polymer film, etc.

Video shows:

Machine's features

1. 3D versatile techniques

3D uv laser is suitable for engraving round shape items, it's very suitable for engraving glass cup, excellent laser beam suit for marking delicate images, round shape items can be well engraving on details, no need to worry the maeking quality. Dotslaser reliable uv laser machine will perform well on it.

2. High machine precision

Precision positioning with the 3D workbench. UV laser machine is equipped with high speed galvanometer scanning system, power laser souce ensures stable performance, laser marking machine with high marking accuracy, it's welcomed in the market, 24 hours continuous working, saves a lot of labor cost and increase productivity, it is also suitable for mass productions.

3.Non-contact process

UV laser use non-contact marking process, less consumables saves processing cost. Friendly to environment, easy to operate and friendly to greenhand, safe operational environment.

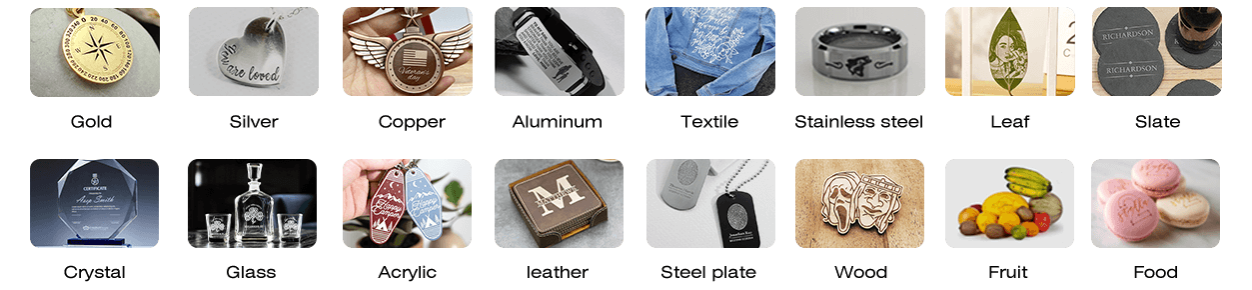

Applicable materials:

Parameter

Maximum power consumption | <1000W |

Marking area:

| 100x100mm,180x180mm |

Min. line width | 0.01mm(According to the materials) |

Minimum character size:

| 0.3 mm (adjusted depending on the material)

|

Laser | |

Laser power | 5W |

Wavelength | 355nm |

Standard marking area:

| 180×180mm |

Max. Processing speed (characters / s)

| 350@180×180

|

Min. Line width:

| 0.01mm

|

Minimum character size:

| Minimum character size:

|

Repeatability:

| ±0.002mm

|

Consumed power | ≤1000W |

Power supply:

| Single phase 200-240VAC 50 / 60Hz

|

Cooling:

| Water |

Why use UV laser mark on glass?

▲UV laser marking on glass is an innovative technology that offers a wide range of benefits. Glass is a popular material that is widely used in various industries, and UV laser marking is becoming increasingly popular due to its unique advantages.

▲One of the primary benefits of UV laser marking on glass is its precision and high resolution. The UV laser has a narrow wavelength, which enables it to create very fine and intricate marks on the glass surface. This is particularly beneficial for the medical and electronics industries, where high-precision markings are required.

▲Another advantage is its durability. The UV laser creates a lasting and resilient mark that is resistant to fading, rubbing, and other environmental factors. This ensures that the marking stays legible and visible over time, which is critical for products that require long-term identification or tracking.

The UV laser demonstrates efficiency and precision in its engraving process on glass, perspex and mirror.

It smoothly navigates through the job at a fair speed, delivering satisfactory results.

Its ability to handle intricate designs and achieve fine details is commendable, making it suitable for applications that require high precision.

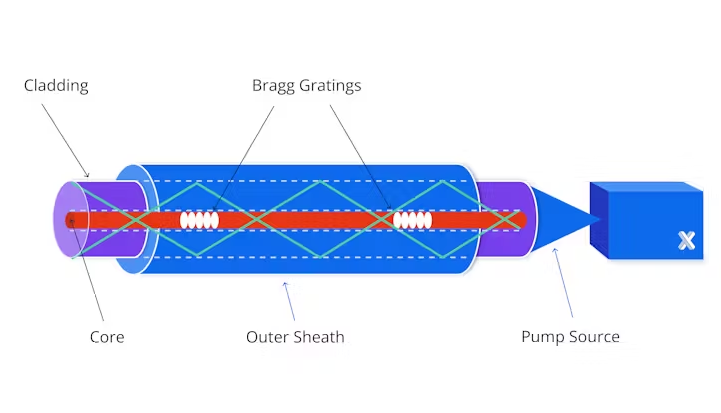

How to distinguish different types of laser?

1. CO2 laser machine mainly concerned with marking and cutting non-materials.

2. YAG laser machine divided into semiconductor lasers, lamp-pumped laser,fiber laser, mainly applied to metal materials and parts made of non metallic materials.

3. Fiber lasers are used principally for cutting and engraving metallic parts. They offer several advantages over other types of lasers, making them a logical choice in industrial applications. Fiber laser high speed, high-precision marking, small unit volume.

4 Main types of glass:

1) Annealed Glass

2) Heat Strengthened Glass.

3) Tempered or Toughened Glass

4) Laminated Glass.

Samples

Shipment and package

Certificate