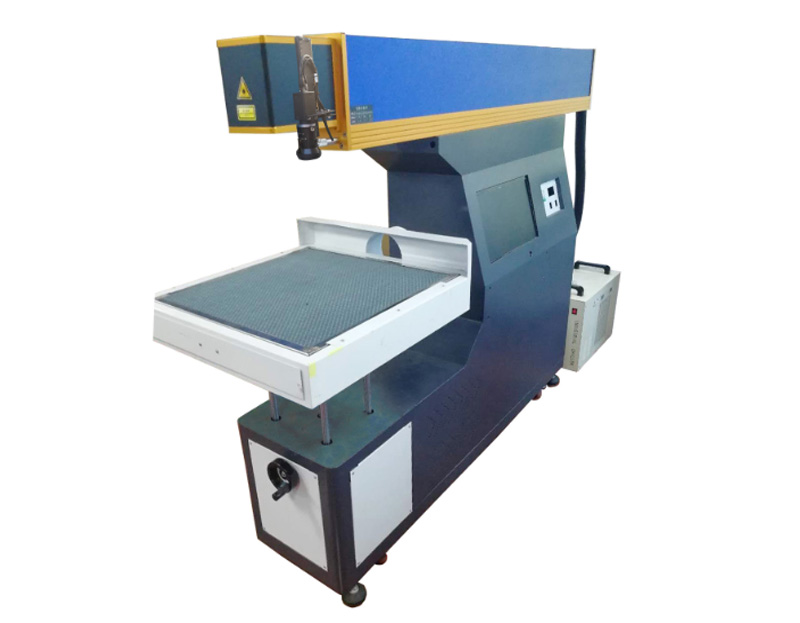

Mold and die repair laser welding machine

Model: DS-200,DS-300,DS-400,DS-500

Professional YAG laser welding machine for mould, die repaire. High performance, cost-efficient.

Product Introduction:

Laser mold welding machine is the current advanced welding equipment. It is a special welding laser equipment specially designed for the mold industry. It is used to repair precision molds and repair errors caused by product production.

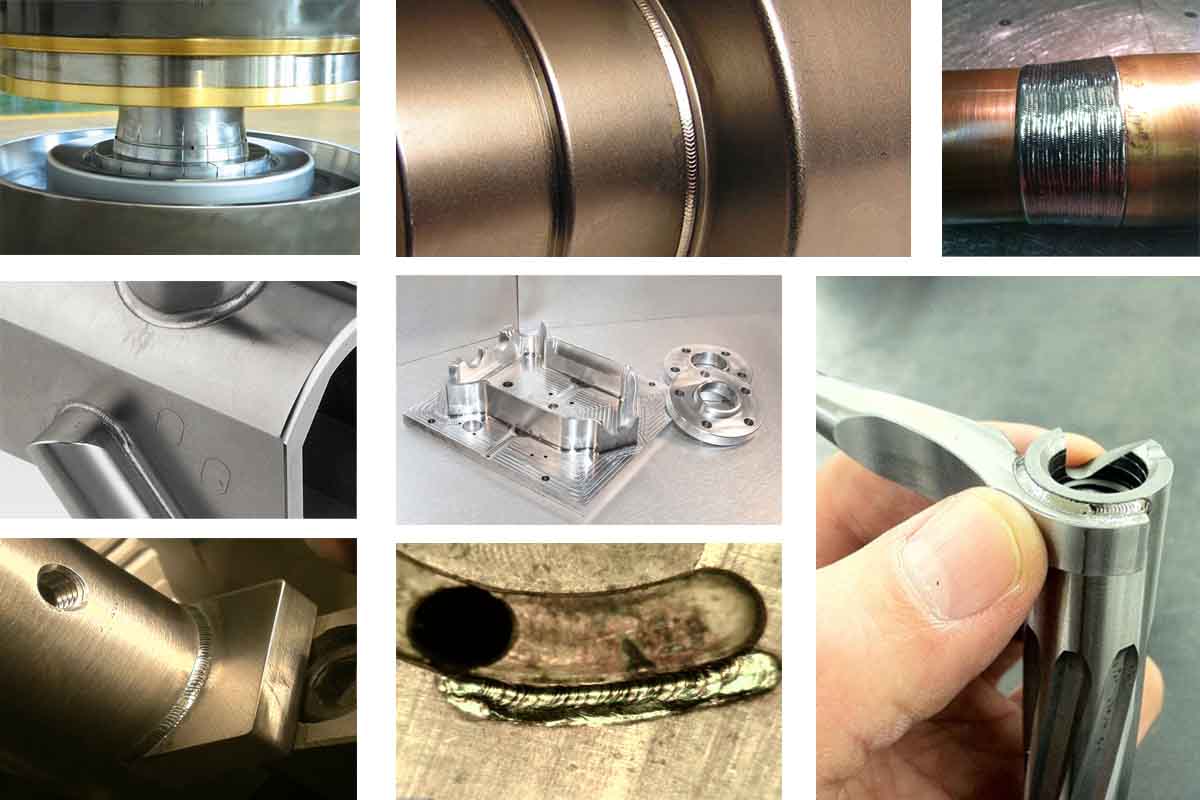

Laser mold welding machine is used in various 3C electronic digital products, mobile phones, toys, automobiles, motorcycles and other mold manufacturing and molding industries. The use of laser welding wire to repair the mold can reuse the used mold again, which greatly saves the production cost of the mold and improves the work efficiency.

Laser mold welding machine technology can also be applied to modify and make up the production design or size of the mold, shorten the production cycle and time of mold product development.

Features of mold laser welding machine

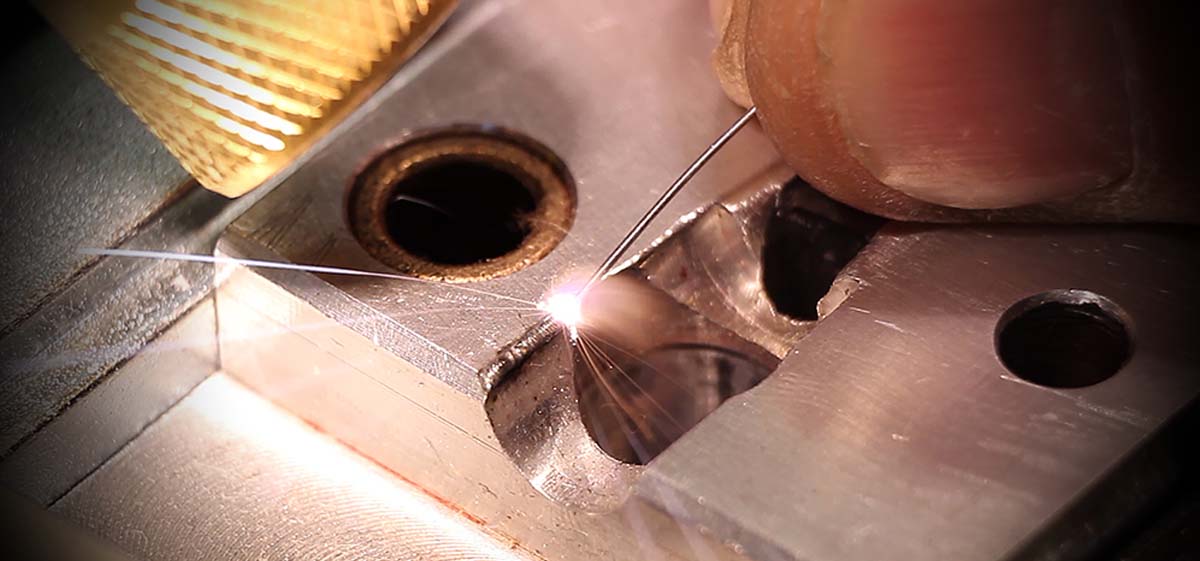

The mold laser repairing is a technology obased on the YAG laser in a high heat energy and a very small point to melt the metal. It effectively handles the welding and repairing work of all small parts, making up for the shortcomings of the traditional argon arc welding technology when repairing fine welding surfaces. The two thresholds of thermal strain and post-treatment are avoided, which greatly saves the production cycle of the mold.

Main advantages of mold laser welding machine

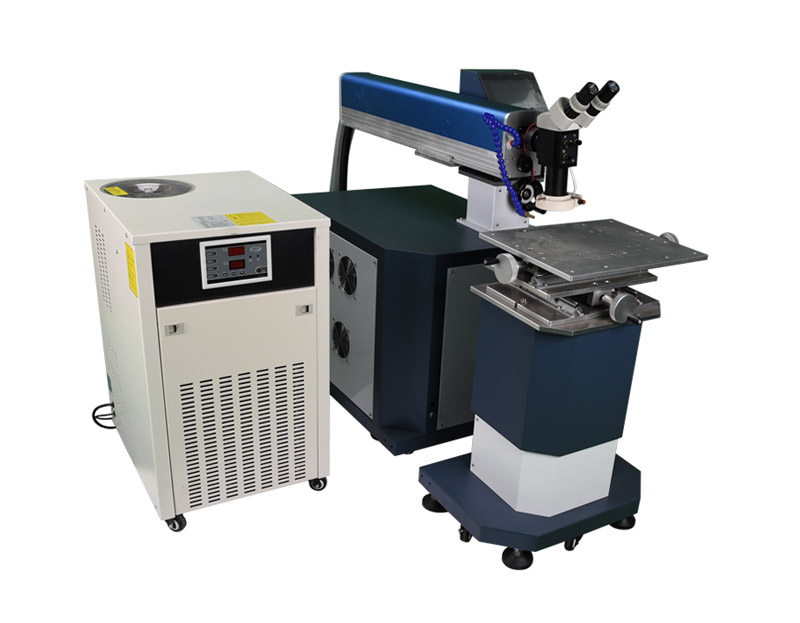

The mold laser welding machine is specially developed for the mold industry. It introduces high-tech and adopts a professional and unique German structure to design the optical path.

1. The mold laser welding machine adopts the ceramic condensing cavity imported from the United Kingdom, which is corrosion-resistant and high-temperature resistant. The service life of the cavity is (8-10) years.Xenon lamp life is more than 8 million times.

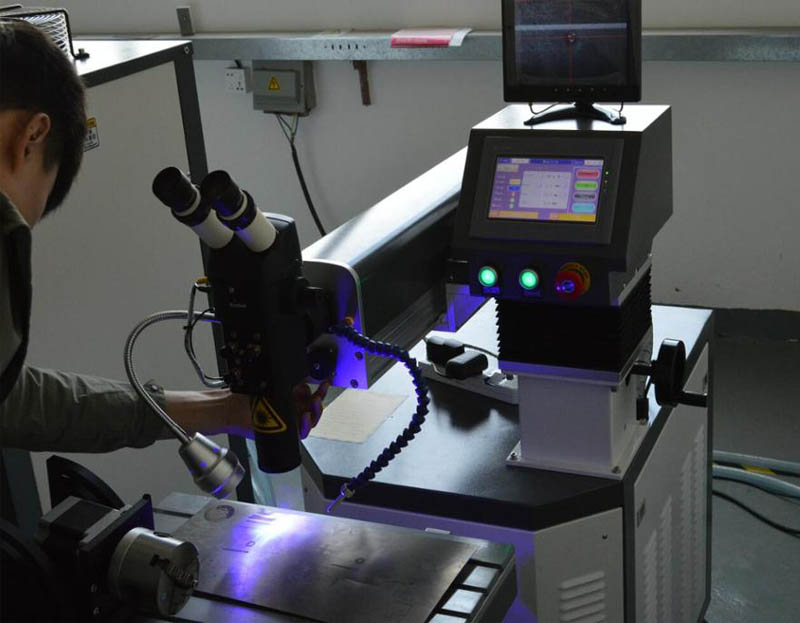

2. The use of the world's most advanced automatic shading system eliminates the stimulation of the laser on the eyes of the staff while working.

3. The laser head of the laser mold welding machine can be rotated 360 degrees, the entire optical path can be rotated 360 degrees, and it can be manually lifted up and down, and the XY axis is pushed back and forth.

4. Mold laser welding machine power parameter adjustment adopts advanced IGBT numerical control, simple operation, fast and durable.

5. The worktable can be motorized or manually.

6. The spot size has been specifically adjusted independently.

Mold laser welding machine applicable material

The materials that can be welded by precision mold laser welding machine are very wide, including: cold working high alloy steel, hot forging high alloy steel, nickel-containing tool steel, high-grade steel, copper alloy, beryllium copper, high toughness aluminum alloy and other metal materials.

Table three-axis travel X = 300mm, Y = 200mm (X, Y can be manually adjusted, Z axis electric lift X, Y electric adjustment, three axis motorized up and down.

Workbench load ≤200KG

Equipment weight 300kg

Machine power supply 220V ± 10% / 50Hz or 380V ± 10% / 50Hz optional.

Parameter:

| Model | DS-200,DS-300,DS-400,DS-500 |

| Wavelength | 1064nm |

| Condenser cavity reflector | Imported ceramic condenser cavity |

| Maximum laser power | 200W/300W/400W/500W |

| Pulse width | 0-20ms |

| Laser frequency | 0-50Hz |

| Spot size adjustable range | 0.3-2mm |

| Cooling system | 1.5p all-in-one |

| Worktable travel | 125x100mm |

| Rated power consumption | 6.5KW |

| Laser model | Nd:YAG pulse |

| Light spot adjustment range | 0.1~0.3mm |

| Light spot size | 0.2~3.0mm |

| Laser output focal length | 80mm/100mm/120mm(optional) |

| Laser cooling | Special water chiller |

| Observation system | Microscope (rotatable 360 degree) or display |

| Protective gas | Argon |

| Welding wire diameter | 0.1mm~0.8mm |

| Power supply | Standard three-phase 380v ± 5% /50Hz/20A; Optional single-phase 220V |

| Dimensions | Machine tool:500×1200×1280mm |

| Chiller:540×650×780mm |

Sample: