YAG laser welding electric devices

YAG laser machine mainly uses for large mold repairing, Yag-controlled laser mold welding machine is to use the high energy heat generated by the laser instantaneously to melt the special purpose welding wire and connect it with the damaged part in the mold, so it can be firmly connected with the original material, after which it shows a re-surface by electric spark and grinding and cutting and some other processing, so the mold is repaired.

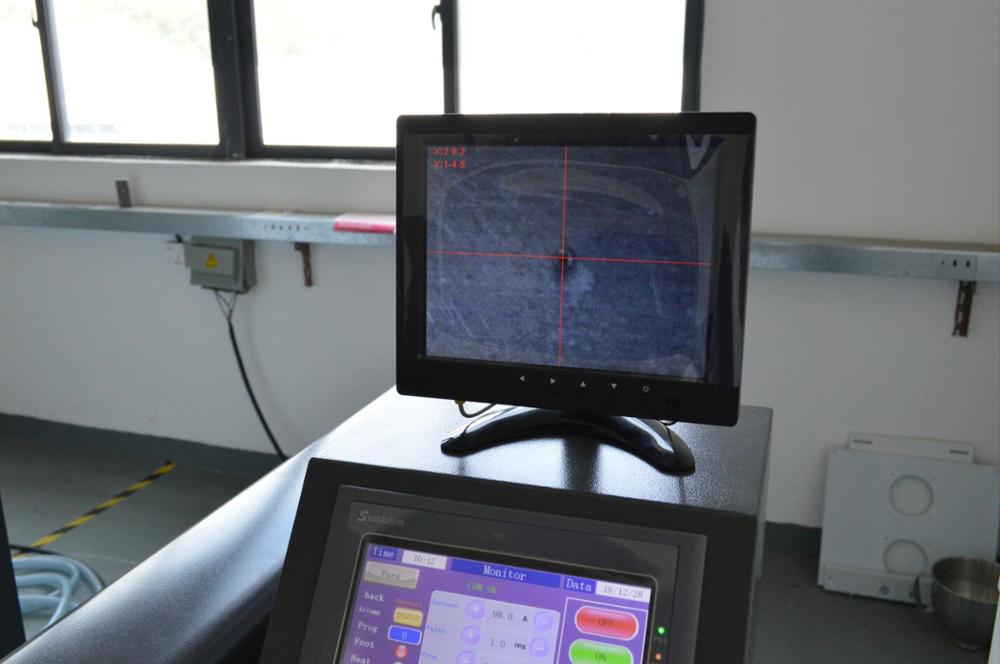

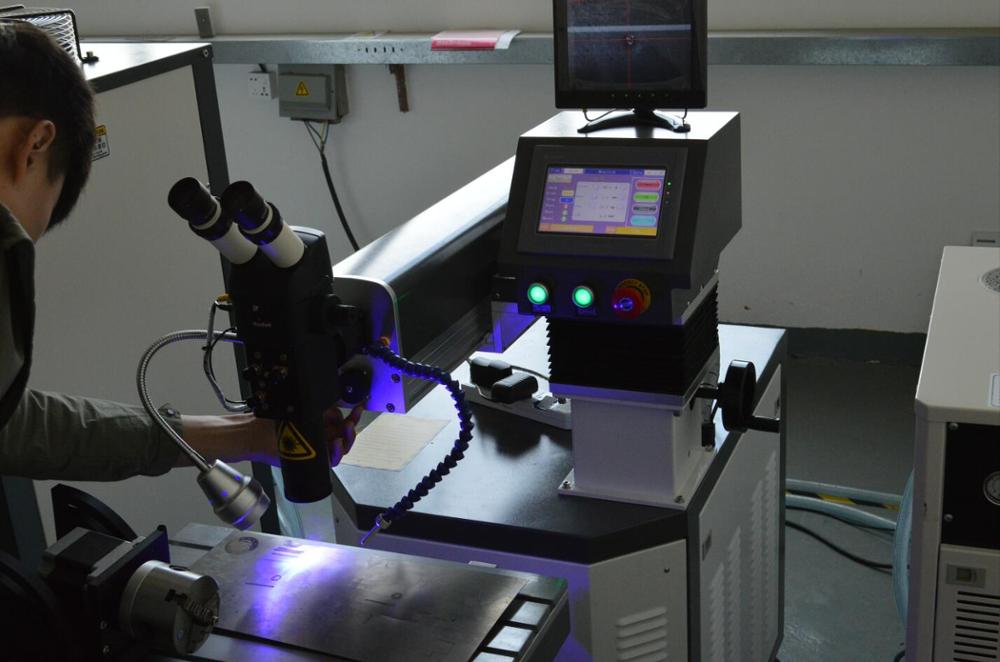

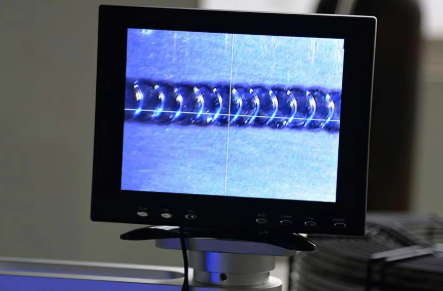

Welding displays:

Product features

1.High precision welding techniques: This 1500W YAG laser welding machine offers high precision and precision for mold repair, ensuring seamless and efficient welding results. It is suitable for a variety of industries, including manufacturing plants, mechanical repair shops, and hotels.

2. Durable: The YAG laser machine has 1 year warranty,it delivers long-lasting performance and reliability. Its robust construction and water-cooling system ensure optimal operation and minimize downtime.

3. Multi-industry compatibility: The machine can be used in a wide range of industries, including clothing stores, building materials stores, energy and mining, and construction engineering, making it a universal solution for a variety of applications.

4. Energy efficiency: Rated at 8-12kw, the machine is energy efficient and can be powered by 380v or 220v, making it suitable for use in different environments.

5. Full support: The seller provides video factory inspection and mechanical test reports to ensure transparency and trust in product quality.

Parameter

NO. | Name | Mould Laser Welding Machine |

1 | Machine model | DS-1500 |

2 | Laser power | 1500W |

3 | Laser wavelength | 1070±10 nm |

4 | Pulse width | 1-100ms |

5 | Laser frequency | 1-1000Hz |

6 | Spot size adjustable range | 0.3-2mm |

7 | Cooling system | Water cooling |

8 | Worktable travel | 200x300mm |

9 | Rated power consumption | 7KW |

10 | Laser model | CW |

11 | Power range | 0-100% |

12 | Observation system | Microscope (rotatable 360 degree) or display |

13 | Protective gas | Argon |

14 | Fiber cable length | 8m |

15 | Power supply | Standard three-phase 220v ± 5% /50Hz/20A; |

Applicable industries:

1. Mobile phone and other electrical metal pieces

2. Electronic components

3. Small sheet metal

4. Pipes

5. Medical device

6. MOLD repair

7. Military manufacturing

8. Advanced instrumentation

Mold laser welding machines are used for metal plate molds, welding, pipe/tube connection welding, as well as the manufacture of sensors, level switches and fine automotive parts mold repair.

Applicable materials:

Laser welding machine is suitable for welding of gold, silver, titanium, nickel, tin, copper, aluminum and other metals. And has been widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automotive and other industries.

Samples welding display:

What're the improvements compared with traditional welding machine?

1. High energy density, low heat input, small heat deformation, narrow and deep melting zone and heat affected zone.

2. High cooling speed, can weld fine weld structure, good joint performance.

3. Compared with contact welding, laser welding eliminates the need for electrodes, reduces daily maintenance costs, and greatly improves work efficiency.

4. Thin weld, large penetration, small taper, high precision, smooth appearance, smooth and beautiful welding appearance .

5. No consumables, small size, flexible processing, low operation and maintenance cost.

6. The laser is transmitted through optical fiber and can be cooperate with pipelines or robots.

Details description:

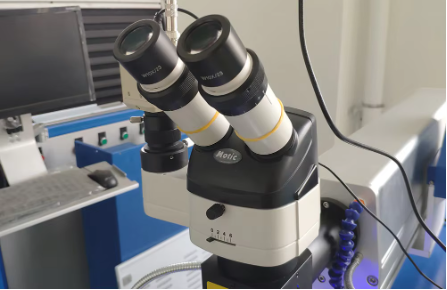

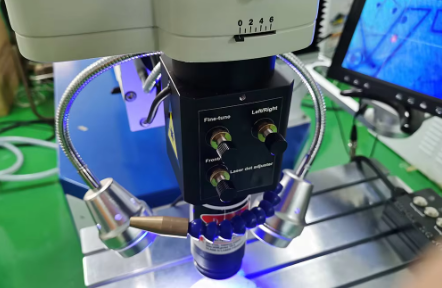

1. High definition microscope

10x microscope magnification, cross cursor indication, and advanced automatic shading system. Keep same with the laser output of the protective gas to ensure a beautiful and smooth solder joint.

2. CCD camera

Using China famous brand CCD camera, LCD screen and red pointer, CCD camera can take pictures of welding details, and transmit the signal to the LCD screen, welding effect is more clear and intuitive.

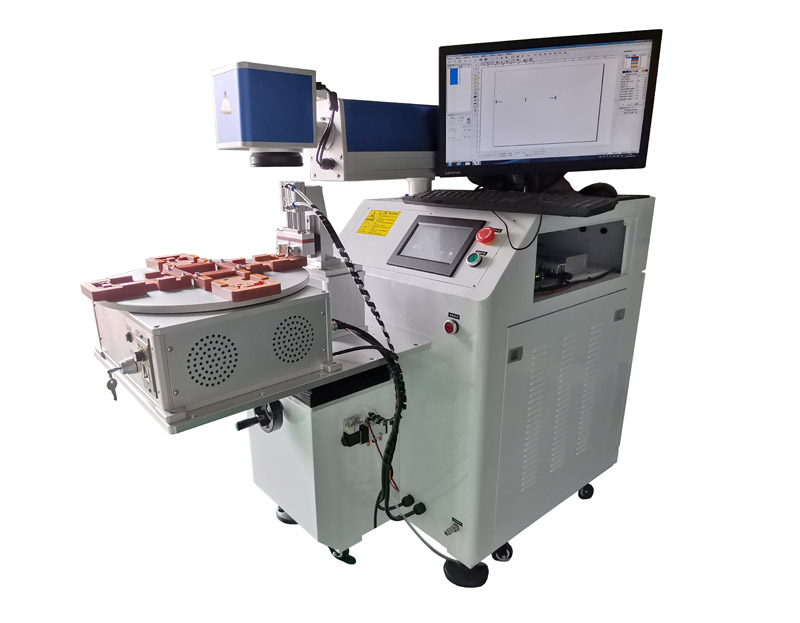

3. X/Y/Z axis movable worktable

For the table electric lift, fixed focus faster. X/Y platform design movement is flexible, can complete a one-time combination welding curve, straight line, single point and other complex processes.

4. Laser head

The laser head can rotate 360 degress, which is more convenient for positioning and welding special-shaped objects.

5. Dual LED lights

Comes standard with 2 high light camera auxiliary lights, white CCD auxiliary lights, and blue microscope auxiliary lights. The auxiliary lighting adopts energy-saving high-light bulb, which has clear image, good heat dissipation effect and will not burn the skin for a long time.

6. High power chiller

Industrial chiller, cooling capacity of 3600W, high-power refrigeration effect is more stable, the use of compressor can quickly cool the laser, to ensure that the laser power is stable, efficient and fast operation.

The exclusive waterless warning and automatic protection system, if there is no water or water flows in the opposite direction, the system alerts and stops working, which can effectively protect the working life of the laser.

Certificate