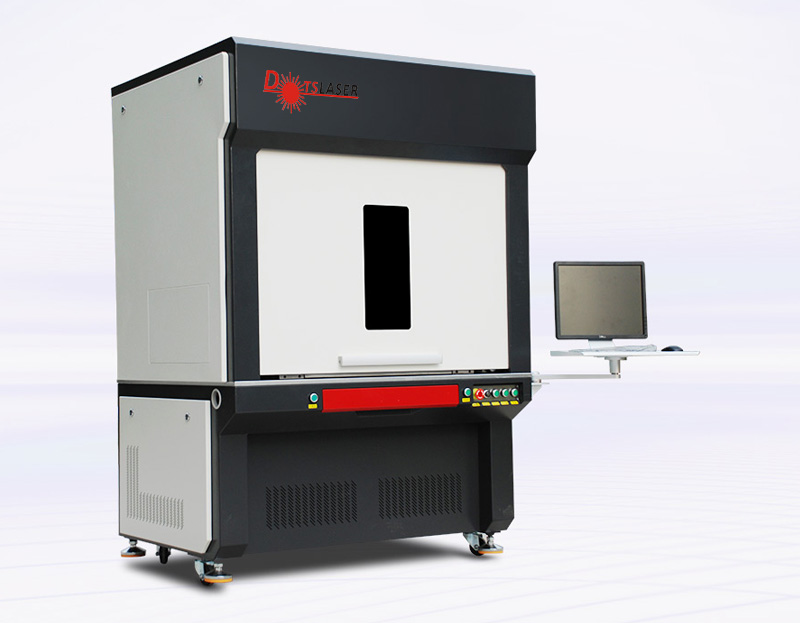

YAG mold laser welding machine

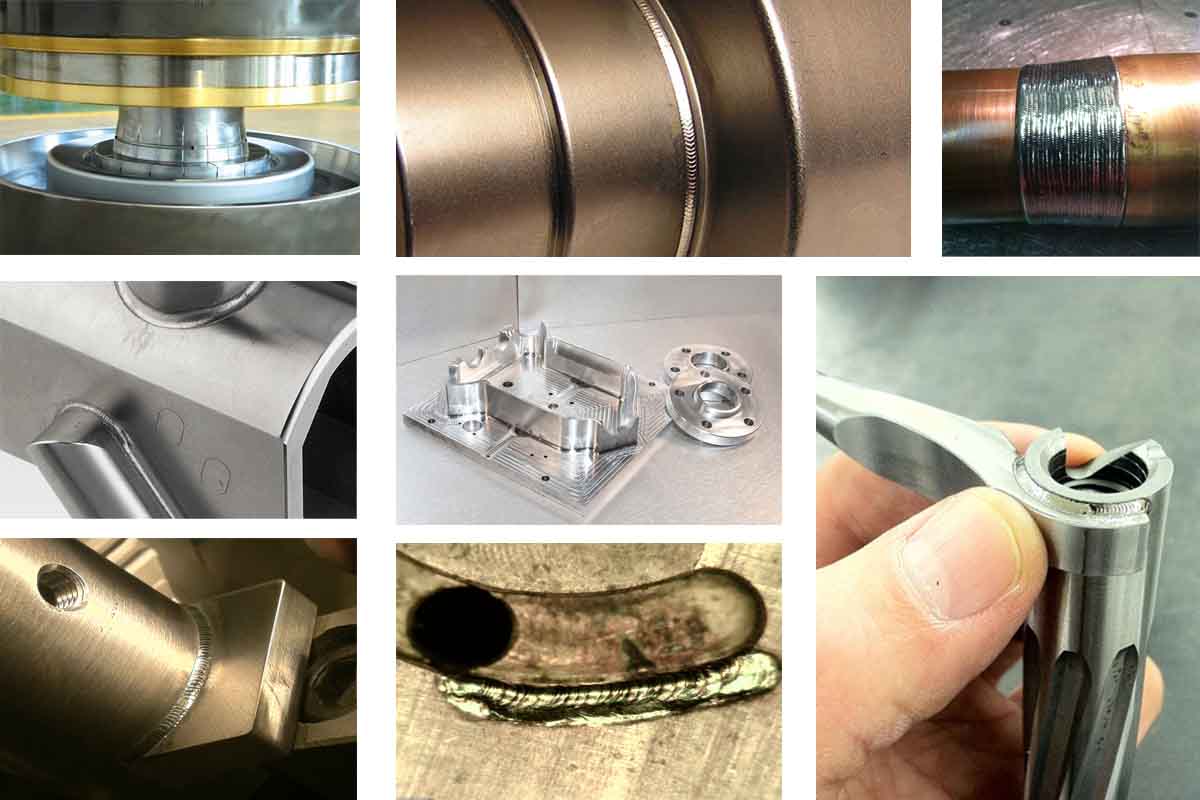

Laser mode welding machine is a advanced equipment, it is specially for welding delicate mode repairing, laser mold welding machine in a variety of 3C electronic digital products, mobile phones, toys, cars, motorcycles and other mold manufacturing and forming industries. The repair of the mold with laser welding wire can make full use of the used mold again, which greatly saves the manufacturing cost of the mold and improves the work efficiency. Laser mold welding machine technology can also be applied to modify and make up for the production design or size of the mold, reducing the production cycle and time of mold product development.

Video shows:

Machine's features

1. Stable laser beam

After pass through the optical fiber, the spot has becaome more uniform and stable, which is improve welding quality quickly. After the laser is focused, a small light spot with high power density, it's specially optimal for mode repair with strong pertinence and best effect.

2. Advanced techniques

Adopt advanced automatic shading system eliminates the stimulation of the laser on the eyes of the staff while working.

3. Resonable and compact design

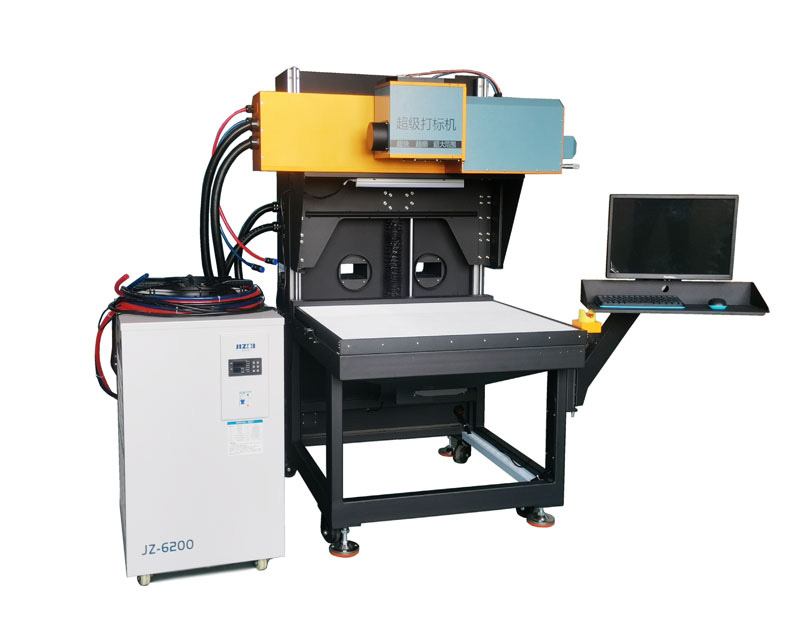

The three-dimensional boom can help you solve the problem of large mold repair without moving the mold, and the joystick controls the translation stage (200mm×300mm Automatic translation stage) movement. It is easy to realize laser repair of large molds and super large molds with sharp tools, long life and high precision;

Parameter

Name | YAG mode laser welding machine |

Mode | DS-1500 |

Laser power | 1500W |

Laser wavelength | 1070±10nm |

Pulse width | 1-100ms |

Laser frequency | 1-1000Hz |

Welding depth | ≤0.3.0mm(depends on materials) |

Spot size adjustable range | 0.3-2mm |

Cooling system | Water cooling |

Worktable travel | 200x300mm |

Rated power consumption | 7KW |

Observation system | Microscope (rotatable 360 degree) or display |

Protective gas | Argon

|

Fiber cable length | 8m |

Power supply | Standard three-phase 220v ± 5% /50Hz/20A; |

Host size/net weight | L 960×W 550×H 680mm / 120 KG |

Table size/net weight | L 610×W 410×H 580mm / 55 KG |

Boom size/net weight | L 1600×W 1070×H 1680mm / 120 KG |

Applicable industries

Laser mode welding uses advanced laser techniques, it's especially design for mode repair, it is used to repair precision molds and repair errors caused by product manufacturing. Laser mould welding machine is used in various 3C electronic digital products, mobile phones, toys, automobiles, motorcycles and other mold manufacturing and molding industries. The use of laser welding wire to repair the mold can reuse the used mold again, which greatly saves the production cost of the mold and improves the work efficiency. Laser mold welding machine technology can also be applied to modify and make up the production design or size of the mold, shorten the production cycle and time of mold product development.

Main components description:

1. Special chiller: which can meet the requirements of long-term, high-power welding with better stability, water chiller control equipment's temperture not overheat or turning lowest temperture, it can improve welding efficiency and productivity greatly.;

2. Gas protection system: so that the product is always protected by argon gas during the welding process, maintaining the original color of the product and improving the welding quality;

3. Three-dimensional boom: to help you solve the problem of large mold repair, no need to move the mold, the joystick controls the translation stage (200mm×300mm);

4. Automatic translation stage movement: it is easy to realize laser repair of large molds and super large molds with sharp tools, long life and high precision;

5. Dedicated welding control system: with extremely high stability, LCD touch screen is easy to operate, learn and understand, smart software supports many kinds of languages transforming;

6. Strong expansibility: can be combined with assembly line, photoelectric detector, pneumatic fixture and other devices for fully automatic processing;

Samples

Work principle of laser welding machine:

◆ It is mainly composed of laser, welding control system, electric lifting table, three-dimensional electric boom, laser welding head and cooling system. The laser welding process works by taking advantage of the excellent directivity and high power density of the laser beam. The laser beam is focused in a very small area by the optical system, and a heat source area with high energy concentration is formed at the welded part in a very short time, so that the welded object is melted and a firm welding spot and seam are formed. Because of its unique controllability: laser pulse width, period, peak power and other parameters can be changed, it has been successfully used in various types of welding.

Components display:

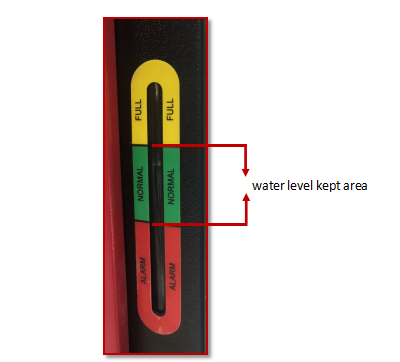

1. The water inlet of the chiller, the cooling water must use pure or distilled water, and the replace is once a month.

2. Water level of chiller, water should keep in the green area.

3. Foot pedal, left pedal control worktable or boom move up, right pedal control worktable or boom move down.

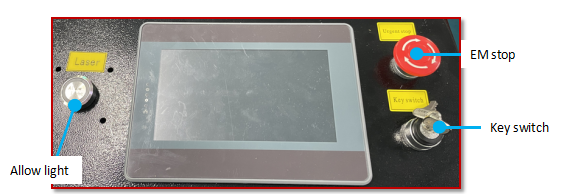

4. EM stop-uses in stop emergency situation.

Key switch-turn on or turn off the whole machine(except water chiler

Allow light output-turn on/off the output functions of laser.

Shipment and package

Warranty

● One year for laser source.

● One year for other accessories,such as galvo head,lens,control board,power supply,consumable parts are not in warranty,such as keyboard and mouse.

● DOTSLASER promises to maintain products which are produced and sent according to a formal contract,and guarantees every repaired machine will function good if used properly.

● DOTSLASER has the rights to repair or replace a product in warranty period if it has a material or technical problem. We will charge for the maintenance under normal circumstances. It will be free if the machine has special problems.

Certificate